Discover why real-world data is essential for effective warehouse AI. Learn how Locus Robotics uses authentic operational data to deliver smarter, scalable, and trustworthy automation.

Learn how warehouse leaders can turn AI from theory into action. Explore practical steps for using data, automation, and human expertise to drive smarter, scalable fulfillment.

Locus Robotics VP of Sales Sean Pineau shares the future of warehouse automation where people, technology, and collaboration drive smarter, more flexible fulfillment.

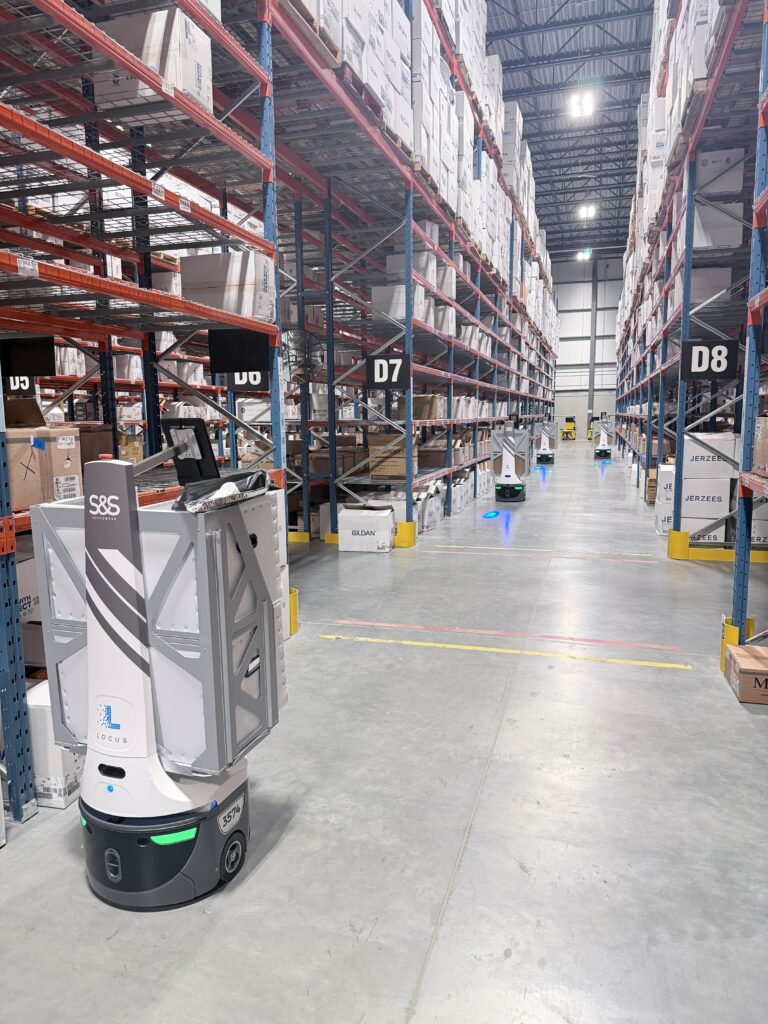

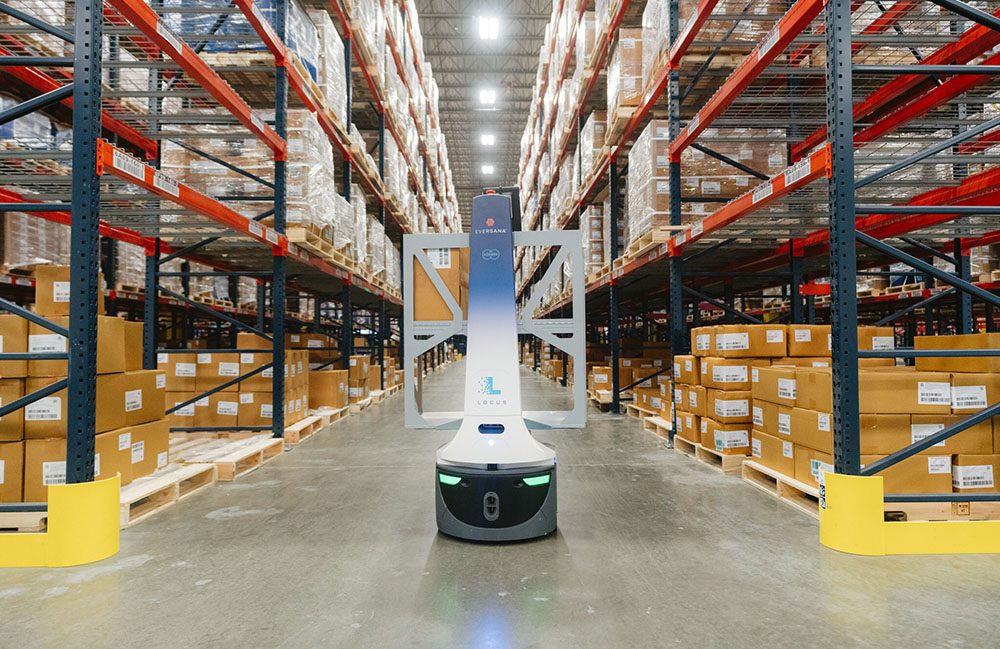

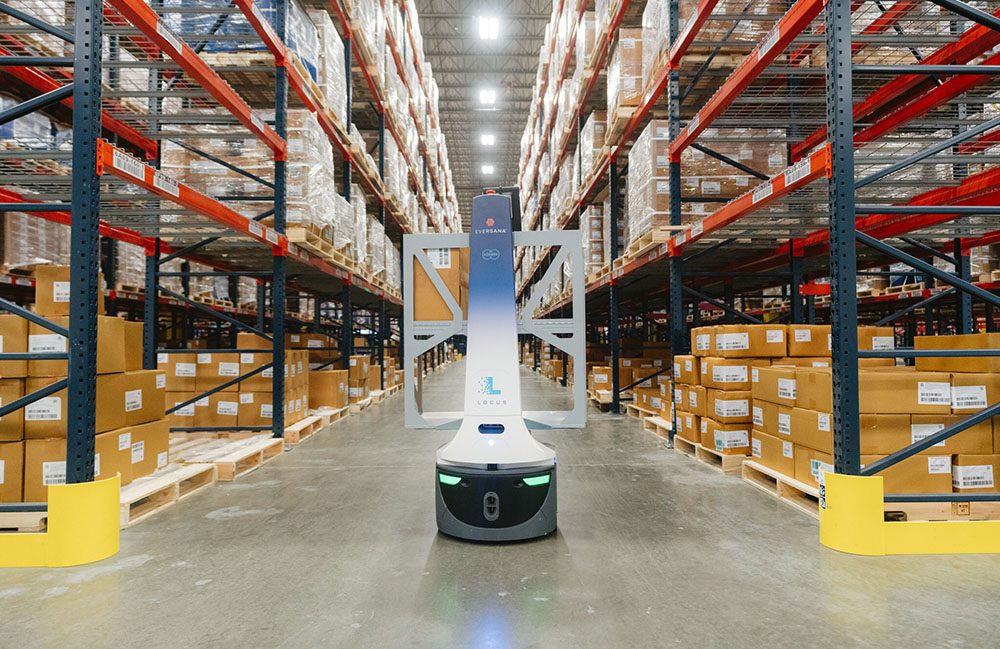

Autonomous mobile robots (AMRs) go far beyond picking. Discover how Locus Robotics’ AMRs power returns, cold-chain, pallet picking, and point-to-point fulfillment at scale.

Facing hiring gaps? See how AMRs, AS/RS, AGVs, and RaaS help warehouses boost throughput, cut errors, and scale fast, without overhauling existing systems.

Discover how 3PLs navigate the Ever-Peak era with automation, intelligent orchestration, and scalable workflows to maintain speed, accuracy, and resilient fulfillment performance year-round.

Explore 2026 workforce predictions on how economic caution, AI adoption, and generational change are reshaping hiring, retention, and career longevity in a rapidly evolving talent market.

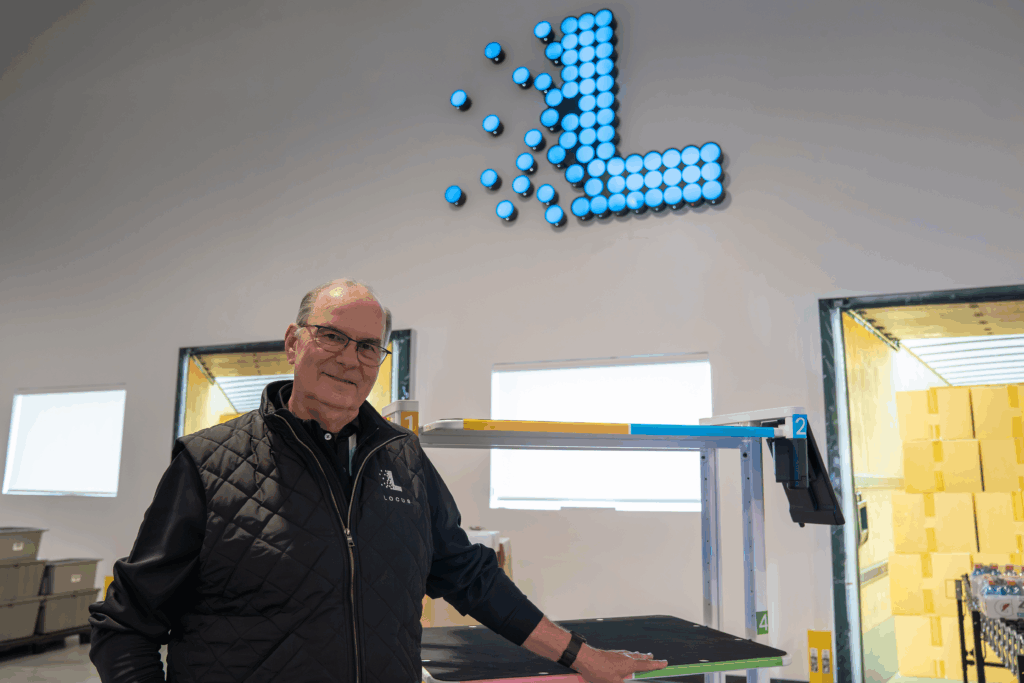

Locus Robotics marks a major milestone as CEO Rick Faulk announces the first shipment of Locus Array, introducing Robots-to-Goods (R2G) automation powered by Agentic and Physical AI.

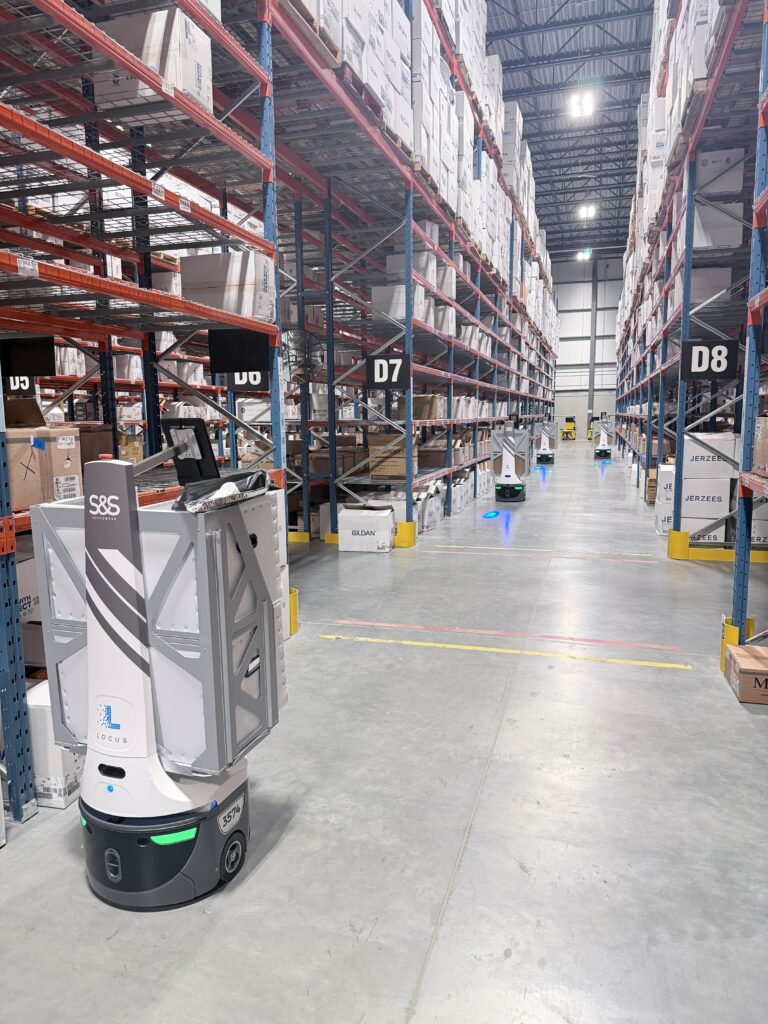

Discover how S&S Activewear transformed warehouse productivity with Locus Robotics to boost throughput 25%, cut training time in half, and achieve record fulfillment speed, balance, and scalability.

Learn how brushing and quishing scams target warehouses during peak season. Discover how to spot malicious QR codes, protect devices, and strengthen warehouse cybersecurity through smarter awareness and verification practices.

Learn key warehouse automation lessons from fulfillment leaders that cover quality, flexibility, visibility, and culture to sustain performance and scale automation success.

Learn what defines a great 3PL partner as Barrett’s Bryan Corbett shares why culture, consistency, and automation, and not just price, drive long-term fulfillment success.

Explore the difference between R2G and G2P warehouse automation. Learn how Locus Array delivers zero-touch fulfillment, flexibility, and scalability to modernize warehouse operations.

Discover how Robots-to-Goods (R2G) enhances warehouse safety, retention, and efficiency while empowering people to thrive alongside robots.

Discover how Agentic and Physical AI work together to create real warehouse intelligence. Learn how Locus Robotics fuses digital reasoning and physical execution to power modern warehouse AI.

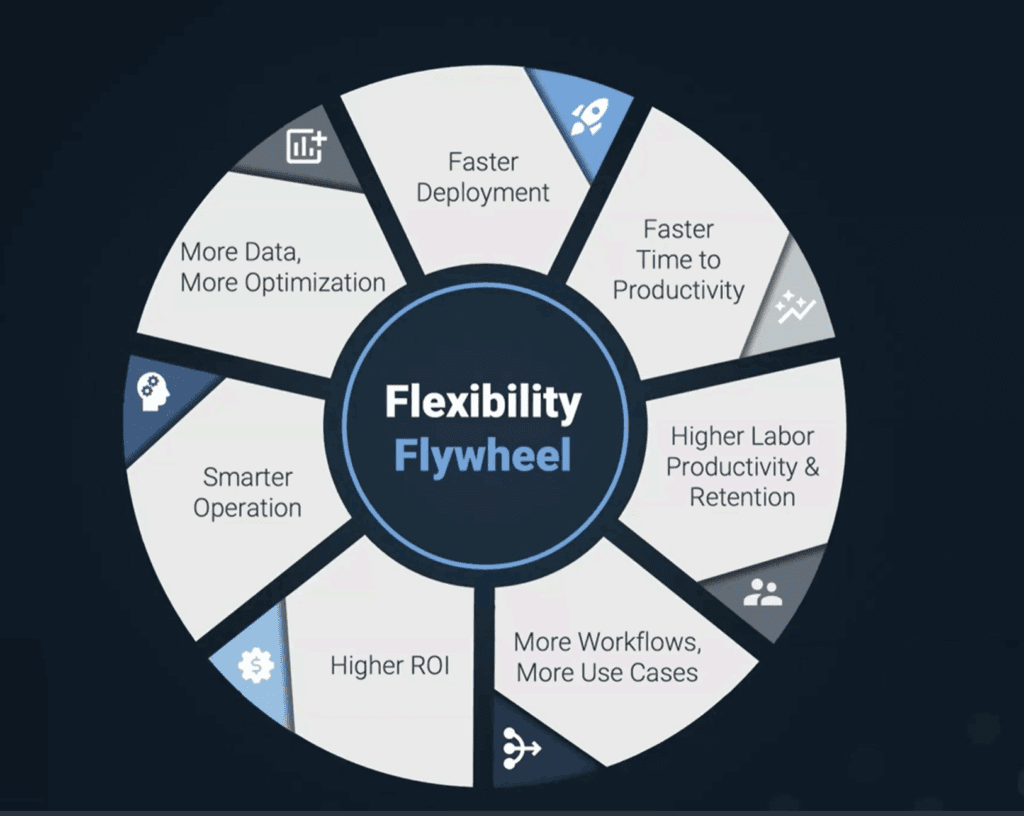

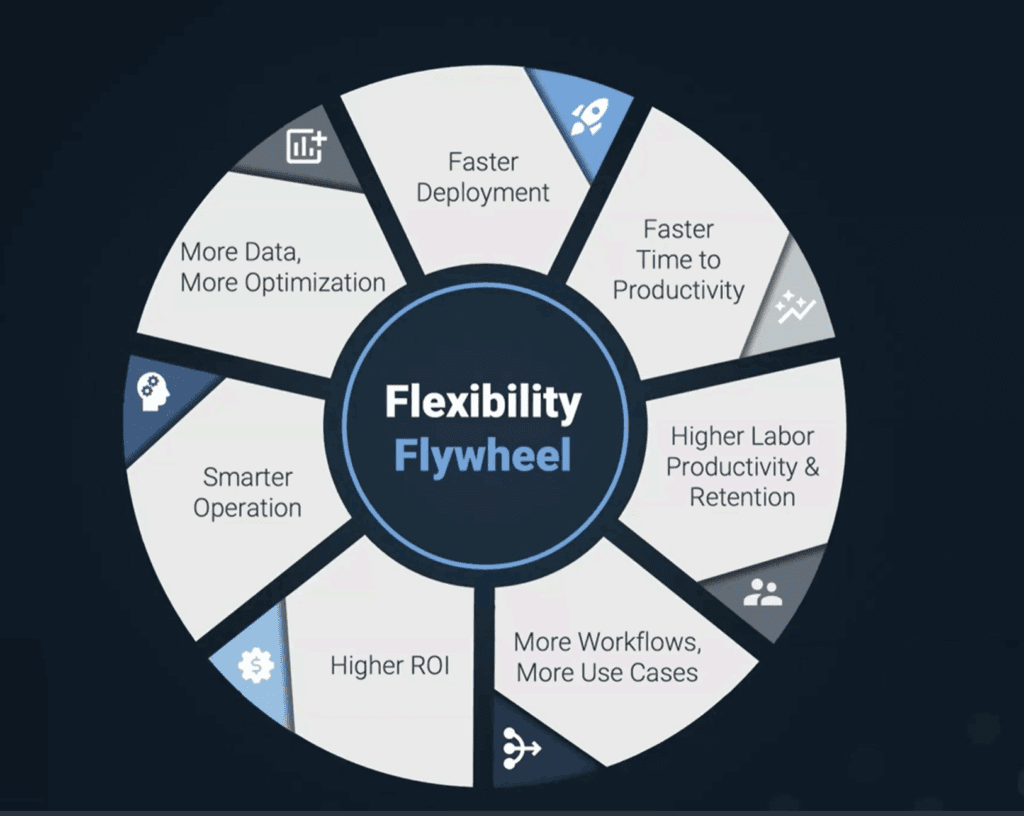

Discover how RaaS for warehouse ROI turns automation into a continuously improving, AI-driven system that boosts flexibility, efficiency, and long-term value without major capital investment.

Warehouse flexibility drives measurable performance. Explore seven levers from deployment to workforce to help fulfillment operations adapt, scale, and evolve with modern warehouse automation.

Explore the 3PL automation playbook for faster ROI, higher consistency, and smarter scaling with expert lessons from Peak Technologies leaders on training, workforce retention, and integrated automation strategy.

Discover how 3PL automation drives faster adoption, predictable performance, and long-term ROI for logistics providers, featuring insights from Peak Technologies leaders on consistency, integration, and workforce success.

Discover how Radial built a repeatable playbook to scale warehouse automation across sites, balancing quality, workforce adoption, and flexibility for long-term fulfillment success.

Explore lessons from Radial on scaling warehouse automation, from multi-site rollouts to workforce adoption, ensuring accuracy, speed, and consistency in 3PL fulfillment.

See how KSP Fulfillment hit 10 million robotic picks with automation strategies for labor stability, accuracy, scalability, and ROI that 3PLs can replicate.

Discover how KSP Fulfillment achieved 10 million robotic picks, stabilizing labor, scaling operations with RaaS, and shaping the future of 3PL automation and customer trust.

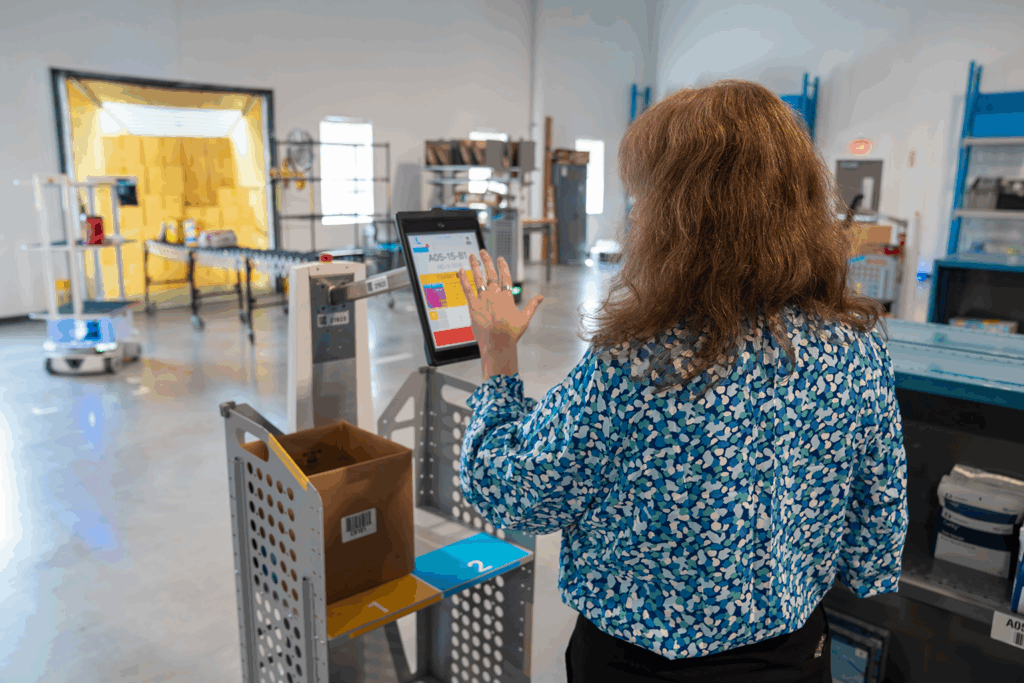

Learn how warehouse automation improves human work by reducing strain, speeding training, boosting safety, and enhancing inclusion.

Discover how warehouse leaders balance automation with the human touch by prioritizing continuous improvement, communication, and flexibility to enhance employee experience and customer outcomes.

Explore the human side of warehouse automation as Tony Altman shares how flexibility, improvement, and trust drive technology adoption that benefits customers and employees.

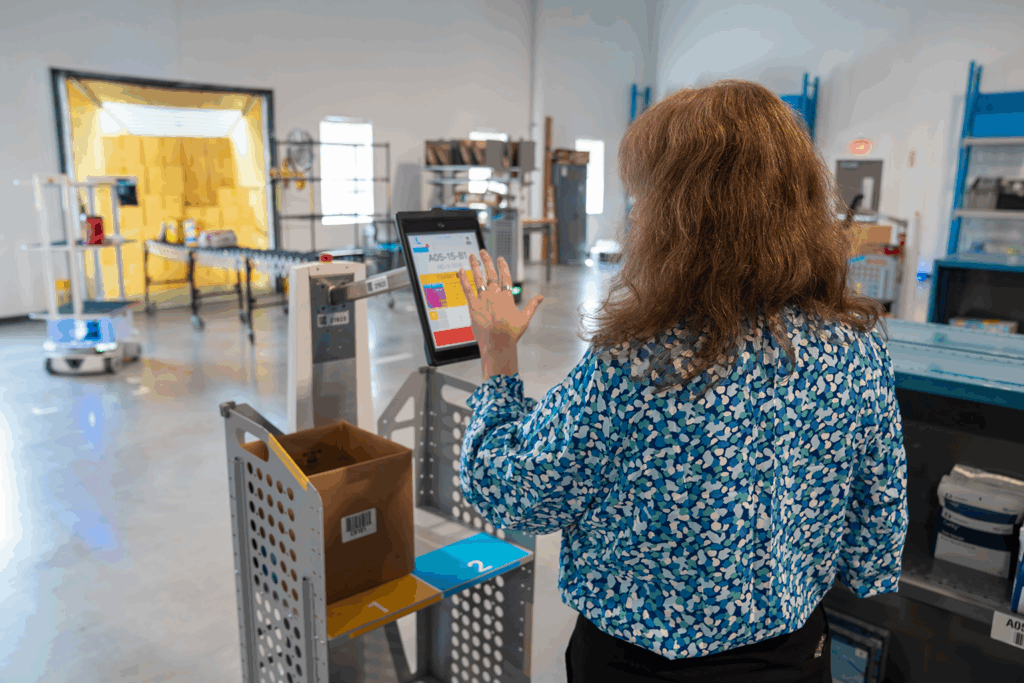

Low-code platforms give warehouse managers flexibility to adapt systems, integrate automation, and boost efficiency without long dev cycles. Learn practical steps from Datex experts in this playbook-style guide.

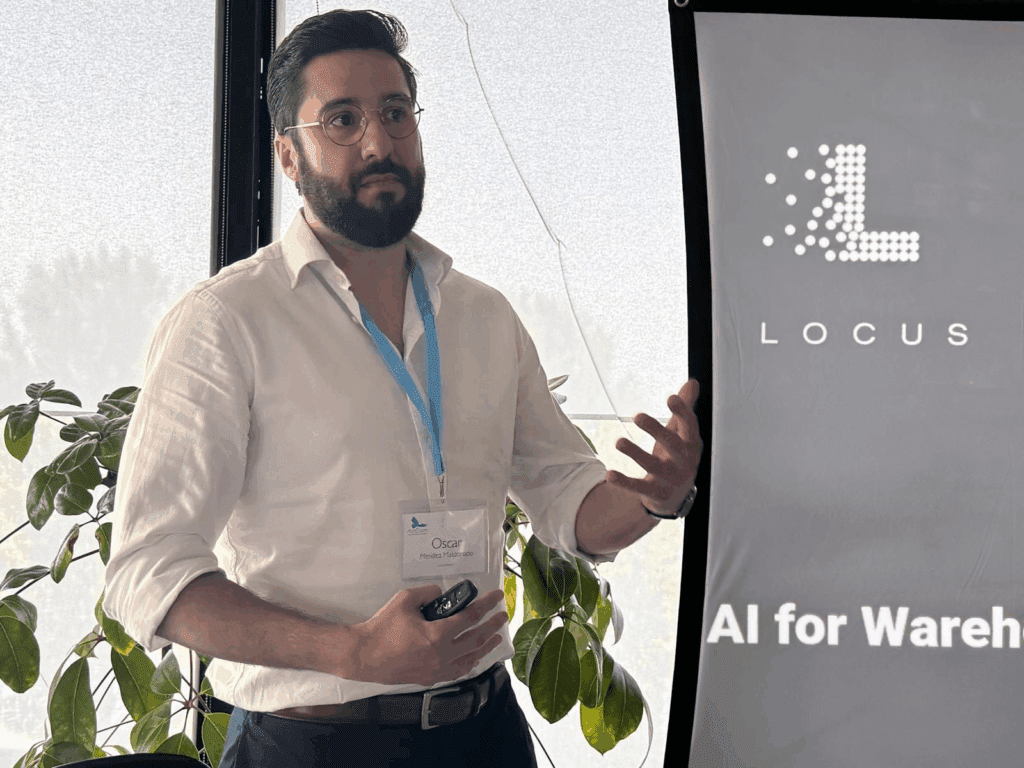

Discover practical ways to apply AI in your warehouse with expert insights from Oscar Mendez, focusing on real ROI, physical AI, and step-by-step implementation strategies.

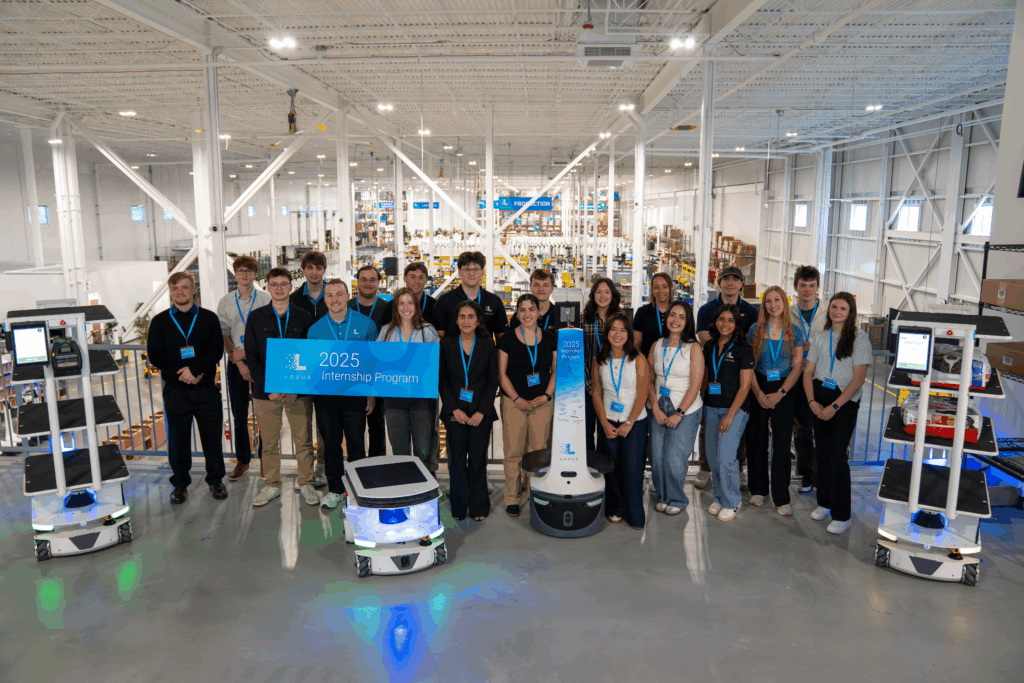

Discover how Locus Robotics’ summer internship program empowered interns across departments to innovate, collaborate, and grow through real-world projects, mentorship, and a supportive, engaging workplace culture.

Prepare your warehouse for peak season with year-round planning, volume modeling, simplified training, and AMR support. Practical steps to boost throughput, protect teams, and meet SLAs with flexibility.

Discover how low-code platforms like Datex Studio help warehouses modernize WMS, boost flexibility, and integrate automation to drive ROI, adaptability, and competitive advantage in complex fulfillment environments.

Discover why optimizing for flexibility, and not storage density, is key to scaling warehouse fulfillment and avoiding throughput bottlenecks in rigid systems.

Explore how Locus Robotics builds real-world AI for warehouses that boosts throughput, reduces labor, and earns warehouse managers’ trust from day one.

Discover the essential WMS features for automation-driven warehouses, from real-time orchestration to robotics integration, that help operations scale, optimize labor, and meet omnichannel and same-day delivery demands.

Discover a step-by-step playbook for selecting the right WMS. Learn how to align teams, fix process gaps, and choose a system that scales with your warehouse and automation goals.

Learn key warehouse automation terms, from AMRs and R2G to UPH and system-directed labor, to align teams, evaluate vendors, and scale smarter. A must-have glossary for warehouse leaders.

Discover what really matters when choosing a Warehouse Management System. Learn why inventory accuracy, scalability, and usability outweigh features and how Made4net supports flexible, real-time warehouse operations.

Learn how Staples Canada began its warehouse automation journey by prioritizing systems, goals, and collaboration. This step-by-step playbook helps you start smart with the right WMS, partners, and KPIs.

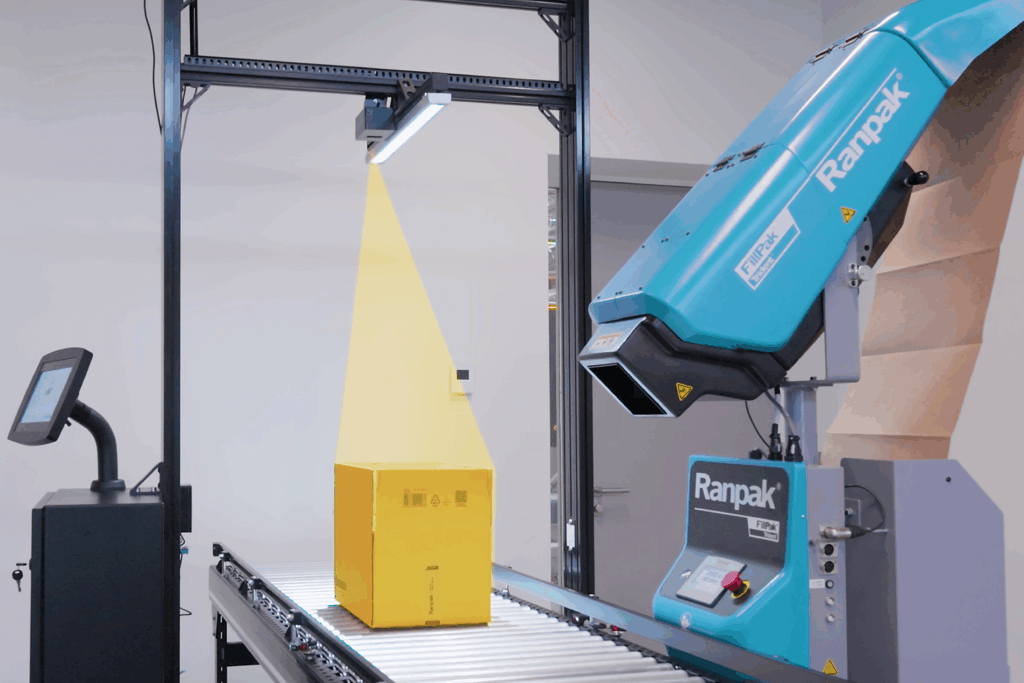

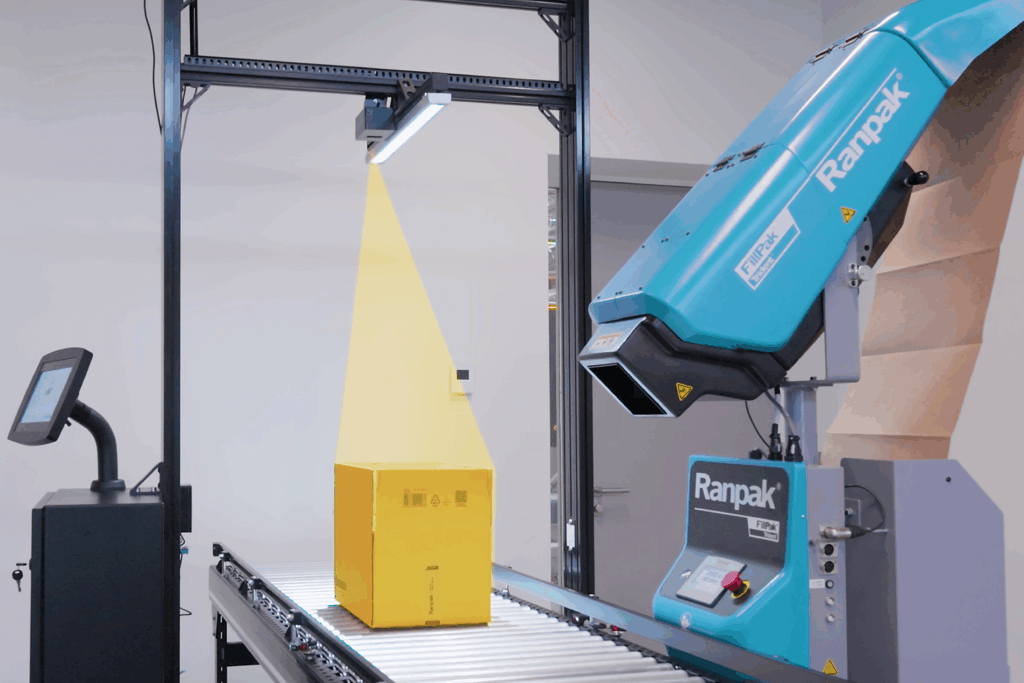

Discover how smarter packaging can kickstart warehouse automation. This step-by-step guide explains how to reduce costs, cut waste, and boost efficiency with modular, right-sized packaging solutions.