WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Robots as Teammates: How Automation Improves Warehouse Work for Humans

Mary Hart, Sr. Content Marketing Manager

When most leaders think about warehouse automation, they focus on throughput, efficiency, and ROI. But beneath those metrics lies a quieter transformation in how automation reshapes the day-to-day experience of warehouse associates.

In recent conversations on the Warehouse Automation Matters podcast, leaders from Staples Canada, Radial, and Motivational Fulfillment & Logistics Services shared how their organizations are using automation to not only move faster but also to make warehouse jobs more rewarding, less stressful, and more sustainable.

Building Better Workdays for Humans with Robots

At Staples Canada, automation was about efficiency, but it was also about building a better workday.

“Our priorities were to improve the quality of our associates’ lives as well as provide exceptional service to our customers,” said Mert Selcuk, Senior Manager of Supply Chain Strategy and Capabilities at Staples Canada.

That perspective shaped every decision that Selcuk made with his team. Autonomous mobile robots (AMRs) were chosen not only for flexibility and scalability, but because they could be integrated with minimal disruption and empower associates rather than burden them. Frontline workers were involved from the beginning, helping to shape the proof-of-concept process so adoption felt like a shared success, not a top-down mandate.

The payoff was tangible. Selcuk recalled an associate who assumed the facility had a slow day when work finished early, only to learn the team had hit its usual volume more quickly. That extra time meant more balance for workers, a reminder that automation can create space in the day rather than compress it.

Motivational Fulfillment echoed this philosophy as President and CEO Tony Altman described automation as a tool for reducing employee strain. “We see automation as a way to improve the employee experience,” he said. “Automation can reduce physical strain and fatigue, improve safety, and create opportunities for skill development and career growth”.

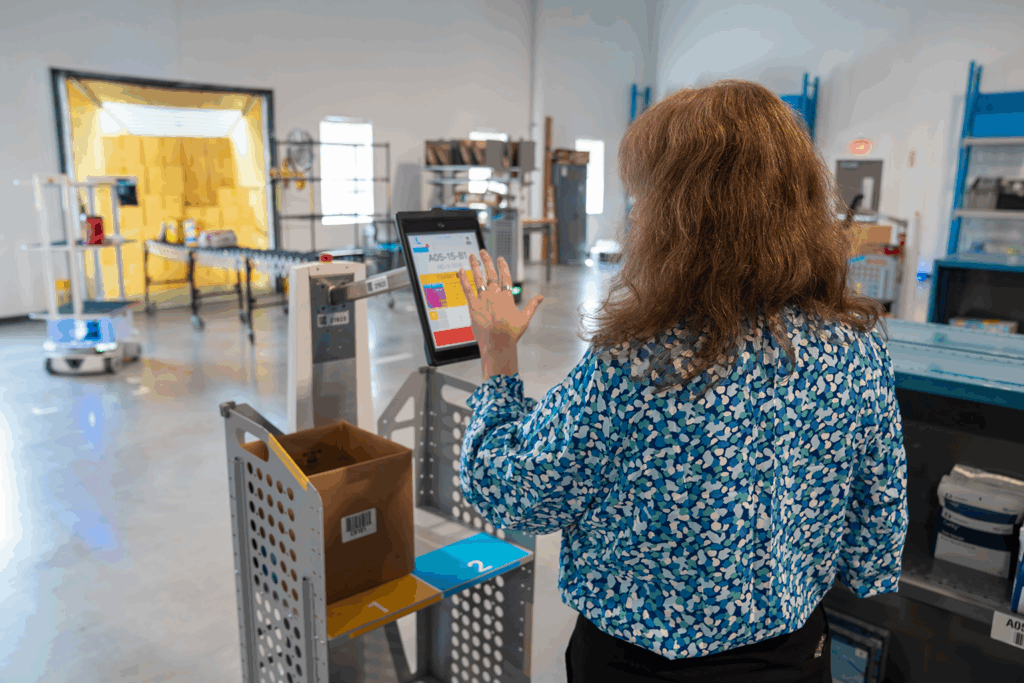

In both organizations, robots are practical teammates that help associates be more efficient and achieve more without sacrificing their well-being.

Training That Builds Confidence

For many warehouses, onboarding is one of the most stressful bottlenecks. Traditional systems require days or even weeks of training, leaving seasonal hires overwhelmed and managers scrambling, and automation has begun to flip that script.

At Radial, the difference was immediate. “The graphical user interface was very intuitive, very easy to use,” said David Welsh, VP of Fulfillment Services Delivery. “A traditional picker may take days and weeks to train, but with automation, we were down to minutes and hours”.

Motivational Fulfillment saw the same pattern, and Altman noted that associates can be trained on Locus robots in less than 10 minutes, which makes scaling up during peak season dramatically easier. The ability to flex the workforce quickly doesn’t just serve customers; it also reduces the stress of steep learning curves for employees.

Faster training also fosters confidence. When associates feel competent and effective sooner, their morale improves, and productivity accelerates. In both companies, automation transformed training from a hurdle into a confidence-building experience.

Inclusion, Engagement, and Recognition

Warehouse automation has also opened new opportunities to engage diverse workforces.

At Radial’s Brownsburg, Indiana site, many associates are Haitian Creole speakers, so multi-language functionality in the robots’ user profiles made a powerful difference. “It’s tailored to their individual needs in both language and preference,” Welsh said. “We’re seeing early adoption, faster buy-in, more engagement from everyone”.

Motivational Fulfillment approached inclusion through communication, as Altman emphasized that new technology is never “sprung” on employees. Instead, management meets with teams to understand pain points and explain why the change matters. “We want to explain how it’s going to make their job easier, improve safety, and improve quality,” Altman explained. That clarity helped employees to see automation as an ally and not a threat.

For Radial and other companies, workforce engagement doesn’t end with training. Radial has introduced dashboards that let associates track their productivity in real time, benchmark themselves against peers, and celebrate progress together. Recognition programs for top performers and most improved employees turn data into pride as associates don’t just see numbers; they see their impact.

Health, Safety, and Retention

Another shared benefit of warehouse automation is employee safety. In Motivational’s facilities, injury rates dropped once robots reduced the amount of walking and repetitive strain tasks required. Associates reported feeling less physically worn down, which in turn boosted morale and retention.

By prioritizing adoption and ownership, companies ensure that safety gains translate into lasting workforce improvements. Retention is harder to measure immediately, but leaders are already seeing promising signals. At Radial, Welsh noted higher associate satisfaction tied to automation, particularly as employees embraced multifunctional roles that broaden their skills and career opportunities. For Motivational, morale and retention were measurably stronger in facilities with robotics compared to those without.

Shared Lessons for Leaders

Taken together, the experiences of Staples Canada, Radial, and Motivational Fulfillment highlight a set of principles any warehouse leader can apply:

- Design automation with people in mind. From solution design to rollout, involve associates early to foster ownership and adoption.

- Simplify the training curve. Make onboarding intuitive and short so new employees feel confident quickly.

- Invest in inclusion. Language accessibility, clear communication, and cultural awareness unlock faster engagement.

- Measure what matters. Productivity dashboards, retention rates, and safety metrics reveal how automation affects both performance and people.

- Think beyond efficiency. Robots reduce strain, open new career pathways, and create a better work-life balance, which are outcomes as valuable as throughput.

The Bigger Picture

As warehouses confront labor shortages, rising costs, and seasonal peaks, automation offers more than a productivity boost. Done thoughtfully, it improves the quality of work life: less strain, faster training, greater inclusion, and stronger engagement.

Across Staples Canada, Radial, and Motivational Fulfillment, the message is consistent. Robots are teammates and that shift may be the most important transformation of all.

Listen to the full episodes of Warehouse Automation Matters with Mert Selcuk of Staples Canada, David Welsh of Radial, and Tony Altman of Motivational Fulfillment to hear more about how warehouse automation improves both operations and the associate experience.