WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Who We Are

We’re redefining warehouse automation with unmatched flexibility, unlimited throughput, and actionable intelligence. LocusONE™, our intelligent, AI-driven, enterprise-grade robotics platform, and our fleet of purpose-built autonomous mobile robots transform workflows, dramatically boosting warehouse productivity, operational efficiency, and workplace safety.

Our award-winning solution improves productivity 2-3X and reduces labor costs, cutting them in half.

Any Environment

Seamless Deployment

Optimized Productivity

Versatility Matters

Any payload. Any process. Any use case.

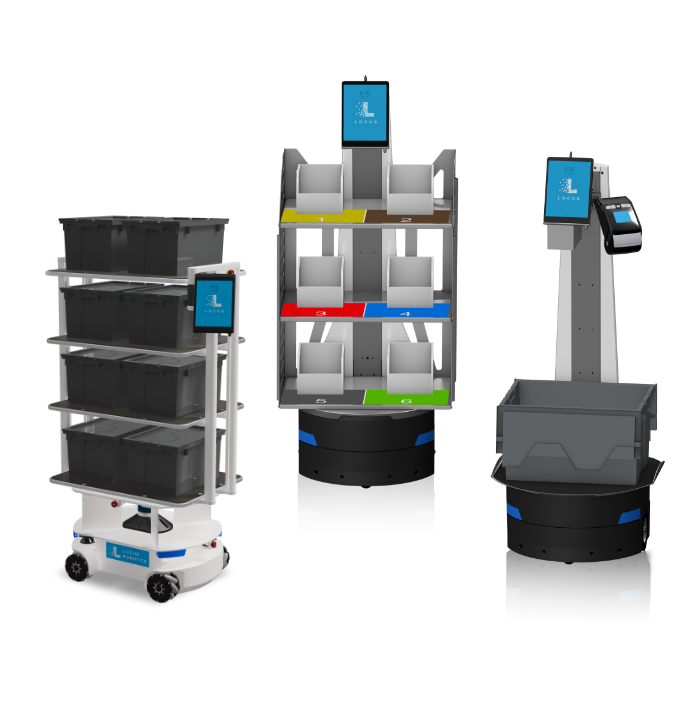

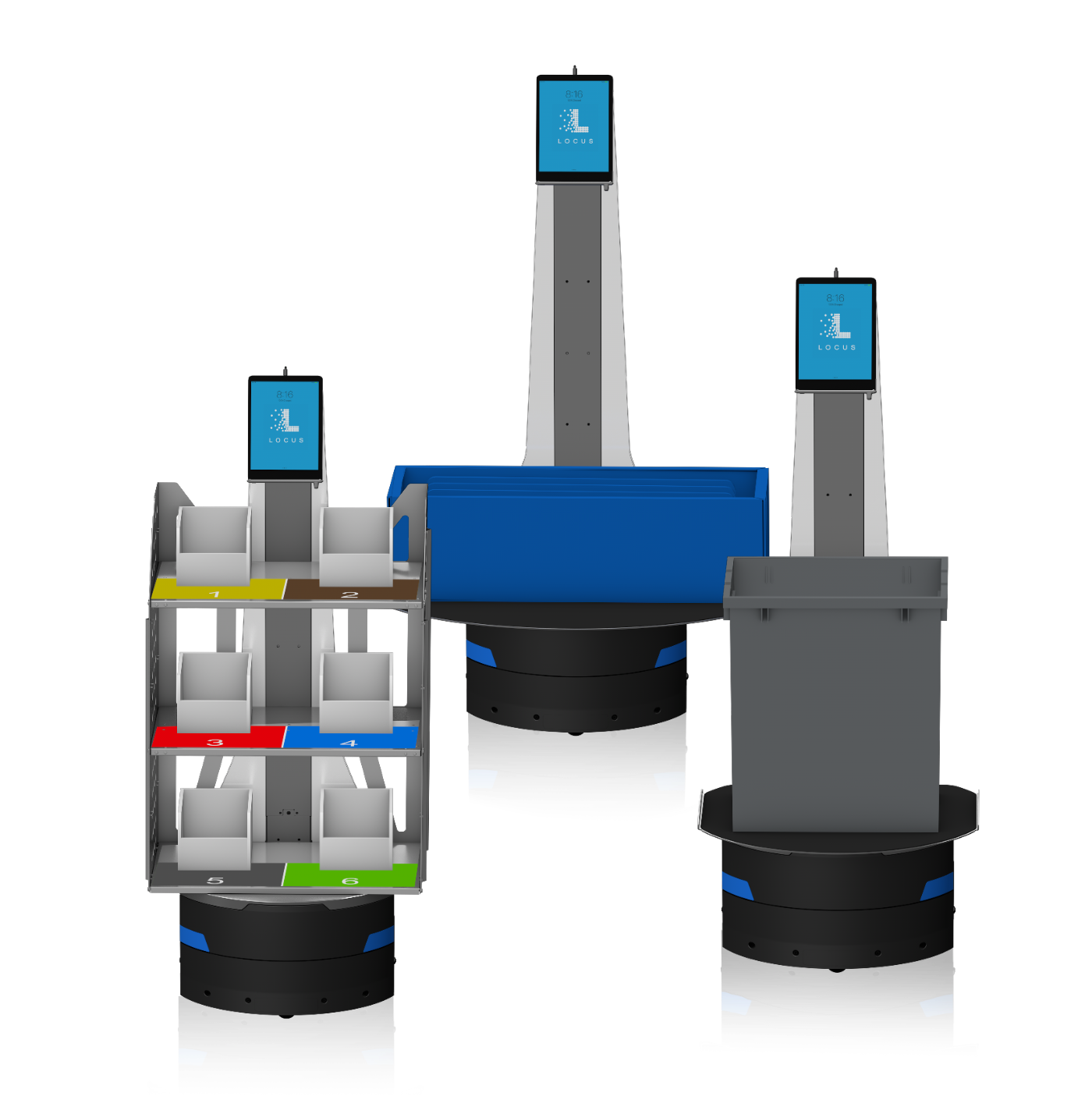

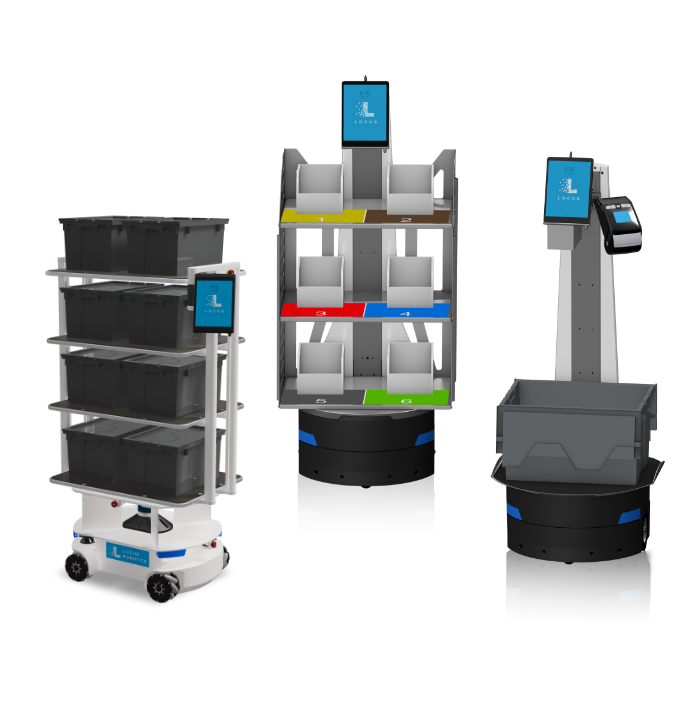

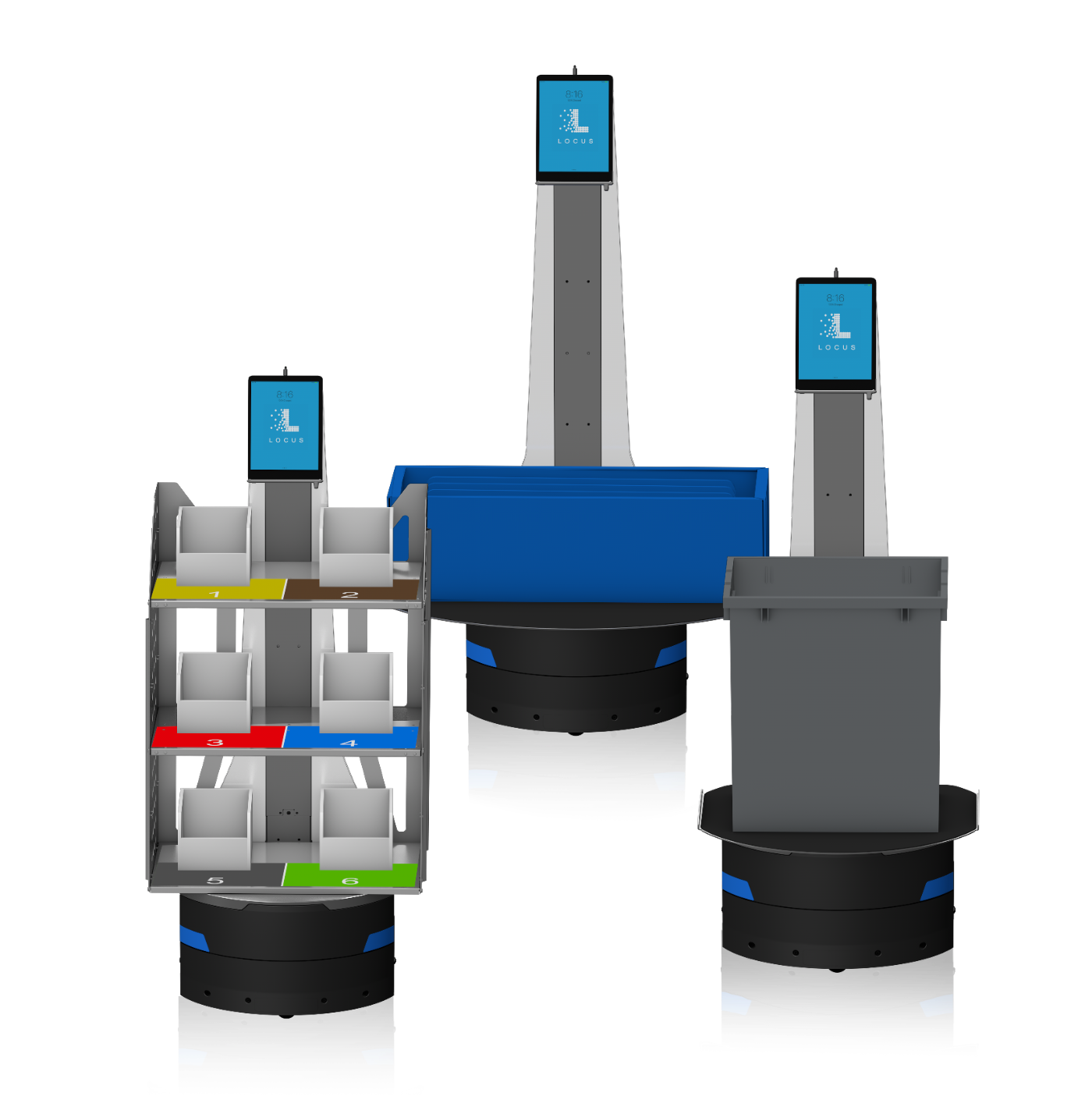

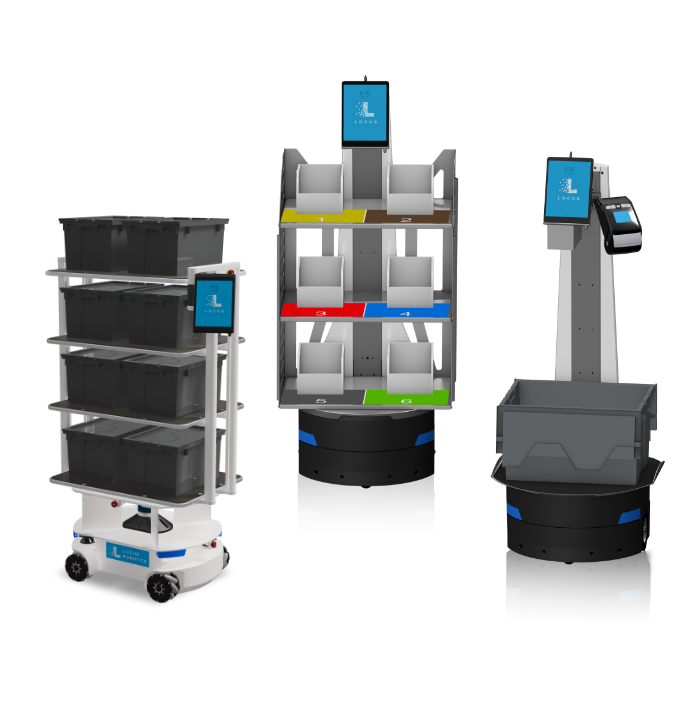

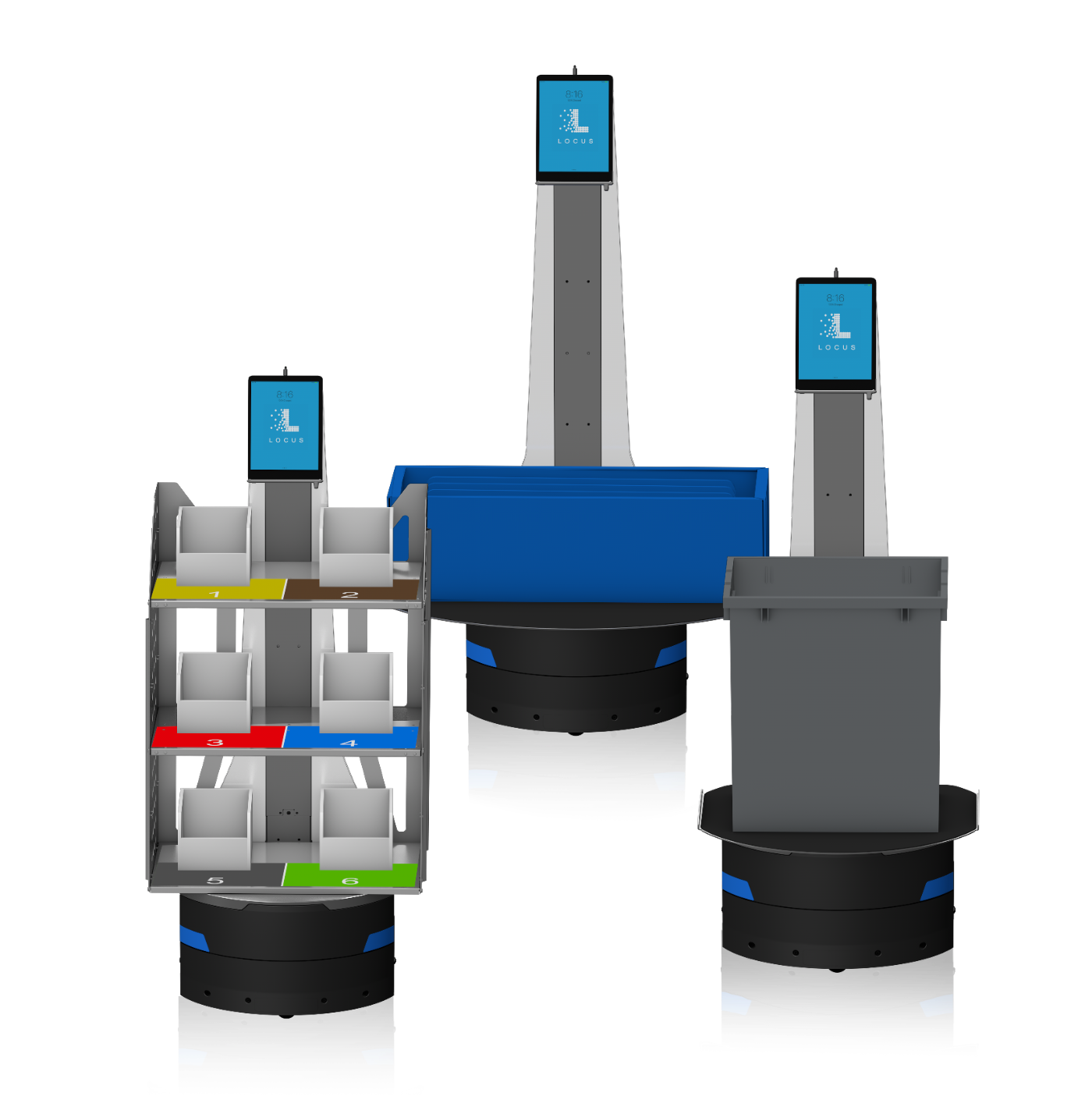

The Locus fleet includes multiple types of robots. Whether you serve one industry or a dozen, Locus' robotic warehouse automation has the right robot for the job.

Picking

Picking

Actively direct workers to their next discrete, case, or batch order picking location

LEARN MOREActively direct workers to their next discrete, case, or batch order picking location

LEARN MOREPutaway

Putaway

Integrate warehouse putaway with true task interleaving to optimize fulfillment centers

LEARN MOREIntegrate warehouse putaway with true task interleaving to optimize fulfillment centers

LEARN MOREPoint-to-Point Transport

Flexible robotic transport system

LEARN MOREMezzanine Management

Optimize multi-level warehouse fulfillment

LEARN MOREIntelligent, AI-Enabled Warehouse Automation

A data science-driven warehouse automation platform for enterprise-wide AMR deployments and performance management.

LocusONE

The LocusONE platform is an industry-defining innovation, offering unmatched flexibility, elastic scalability, and advanced intelligence. With an integrated suite of hardware, software, AI-driven business intelligence, and comprehensive service, support, and security, LocusONE delivers a seamless, scalable, and data-driven approach to warehouse automation.

LEARN MORE

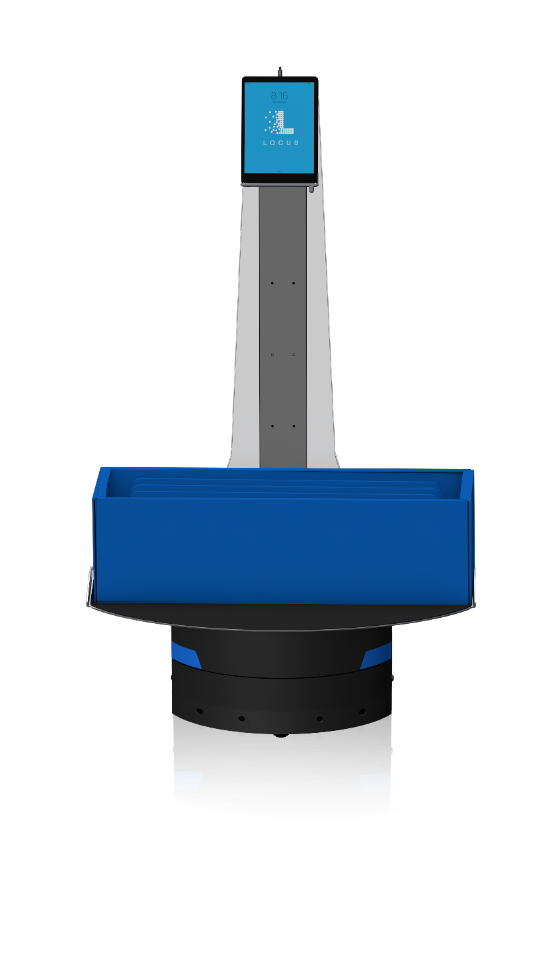

Locus Origin

Designed for high-volume order fulfillment, Locus Origin is a collaborative mobile robot that enhances productivity by over 2x. Its adaptable design supports multi-level shelving and a variety of container types, making it suitable for tasks like picking, putaway, and replenishment. The robot's intuitive user interface facilitates quick training and efficient human-robot collaboration.

LEARN MORE

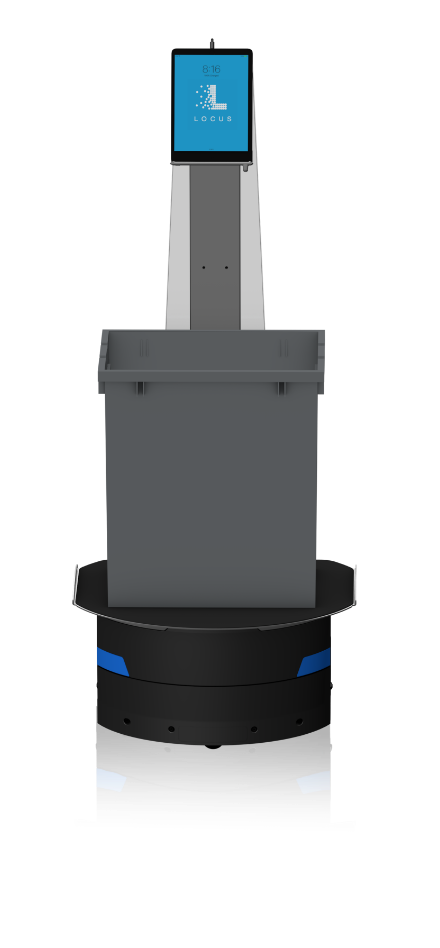

Locus Vector

Engineered for material handling, Locus Vector boasts a high payload capacity and omnidirectional mobility. Its compact design allows it to navigate diverse environments, performing tasks such as case picking and point-to-point transport. This versatility makes it ideal for handling heavier loads and supporting diverse warehouse operations.

LEARN MORE

Customers

Metrics that Matter

6-8

Months to ROI

2-3x

Productivity Gains

50%

Faster Cycle Time

4-6

Weeks to Go-Live

300+

Facilities Contracted

18

Countries

13k+

Bots in the Field

700+

Bots at One Site

Ready To Get Started?

Let’s talk about your operation and how Locus automated robotic system can help you achieve your goals, today and into the future.