WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

In warehouse automation, “AI” has become a catch-all term that is applied to everything from dashboards to genuine autonomous reasoning, but not all artificial intelligence delivers results.

Some systems think but don’t act, while others act but don’t think. The future belongs to those that can do both.

That’s where Locus Robotics stands apart with agents that reason and robots that act, unified by a single orchestration platform that turns digital intent into physical outcomes instantly and at scale.

Two Halves of the Intelligence Spectrum

True warehouse intelligence lives at the intersection of digital reasoning and physical execution.

Inside every modern warehouse, there are two essential domains of intelligence that should work in concert, although in practice, they rarely do:

- Agentic AI (Digital Space): Software “agents” that reason, plan, and make decisions to optimize workflows, balance labor, and orchestrate orders.

- Physical AI (Real World): Robots and sensors that perceive, move, grasp, and execute tasks safely, intelligently, and efficiently on the floor.

In an ideal environment, these two layers constantly inform one another as digital agents make intelligent decisions based on real-world data, and physical robots execute those decisions while feeding new data back into the system.

However, most vendors specialize in only one half of the spectrum, as software providers build digital systems that model and predict but stop short of physical execution. Some robotics companies, meanwhile, excel at movement and safety but lack the digital intelligence to adapt or self-optimize. And across the industry, many companies lack the data, the expertise, or both — preventing them from connecting digital intelligence with real-world action at scale.

The real opportunity — and what we’ve built at Locus Robotics — lies in fusing both sides into a single, vertically integrated system where every decision becomes a physical action, and every action drives smarter decisions.

Closing the Loop Between Reasoning and Action

That’s why we designed LocusONE™ as a complete intelligence loop where digital reasoning and physical execution continually inform each other.

Within LocusONE™, Agentic AI serves as the reasoning layer while our System-Directed Labor (SDL) engine continuously evaluates orders, priorities, and labor availability. It optimizes routes and thinks holistically about how every associate and robot can work together to maximize throughput.

Physical AI, in turn, executes those decisions instantly and securely. Each Locus Robot senses, reasons, navigates, and collaborates safely with people and other automation systems. The orchestrator agent closes the loop: as tasks are completed, data flows back into the reasoning layer, where the AI refines future decisions.

That fusion of planning and execution is what we call Physical AI in motion: intelligence that doesn’t just predict outcomes but creates them.

Why Most AI Stops Halfway

Across the industry, many companies talk about AI, but most deploy only digital intelligence, which is great at plans and predictions, but weak at outcomes.

Digital-only AI forecasts and simulates, but it stops at the screen, so humans still have to turn insight into motion, which slows decisions and reduces throughput.

Conversely, robotics that focus purely on motion excel at precision, but without digital reasoning, they can’t adapt to real-time change. The result is a widening gap between intelligence and impact.

Bridging the Gap: Agentic + Physical AI

Locus Robotics bridges that gap by merging both domains into one architecture.

- Our Agentic AI analyzes real-time order data, hourly progress, and workforce capacity to determine the optimal next action.

- Our Physical AI executes that plan autonomously by navigating complex environments and collaborating safely with humans.

- Our Orchestration Layer functions as an agent, linking the two in milliseconds. This guarantees that every digital decision translates into a physical action, and each action feeds new insights back into the system.

That continuous feedback loop transforms warehouses from reactive operations into self-optimizing ecosystems.

Reinforcing the “Real AI” Foundation

As our Head of AI and Data Science, Dr. Oscar Mendez, outlined in his post “Real AI for Real Warehouses”, true warehouse AI must be Physical, Trustworthy, and Holistic. Those three traits define what we mean by real intelligence in motion.

- Physical because intelligence must live in the real world and is embedded in robots that move, sense, and adapt.

- Trustworthy because decisions must be explainable and transparent to operators.

- Holistic because AI should orchestrate the entire warehouse, not just a single workflow.

Building on that foundation, every insight from our agentic layer is grounded in real operational data from tens of GB per second of robot and workflow intelligence across more than 350 sites and 6 billion picks. Instead of lab-level experimentation, this AI learns from real warehouses every second of every day.

And, like Dr. Mendez’s “AI Complexity Ladder,” our roadmap builds business value incrementally, from perception and navigation to full-fleet orchestration, ensuring each layer of intelligence is proven, practical, and delivering ROI before we scale further.

How Agentic + Physical AI Show Up on the Floor

Consider a high-volume fulfillment center running on LocusONE™. The agentic layer continuously monitors order flow, and when a surge hits and hundreds of new e-commerce orders drop in within minutes, the AI reprioritizes picks, reroutes Locus Robots, and reallocates human associates where they’re most effective.

There’s no downtime, no manual rescheduling as robots adapt instantly, dynamically plan paths, and associates receive new missions in seconds.

That’s what happens when agents reason and robots act as one system.

Why This Matters Now

Warehouses are evolving from data-rich, but decision-poor environments into operations where insight and action are inseparable.

Agentic AI alone can model the optimal flow, but it can’t move a product.

Physical AI alone can move a product, but it can’t decide which one or when.

Together, they deliver true agility with operations that sense, decide, and act as a single intelligent system that understands the warehouse.

As I wrote in my “Nine Years at Locus” reflection, the next phase of automation is about smarter orchestration that closes the gap between prediction and performance, and Agentic and Physical AI are the mechanisms for that shift.

A Fused Future

This fusion also enables Locus to continually expand our platform. As we add new robot types like Locus Array, which reduces touches per pick by 90%, larger payload robots, and AI vision modules, LocusONE™ acts as the central system that integrates all of them, with reasoning, acting, and learning functioning as one ecosystem.

We’re not building individual tools; we’re building a living network of intelligence that connects digital reasoning with physical capability in what we call decisions that move.

Final Thoughts

The future of warehouse automation will belong to companies that can both think and act instantly, safely, and at scale.

At Locus Robotics, we’re proud to lead that evolution. Our customers aren’t choosing between Agentic AI and Physical AI — they’re choosing both, fused, orchestrated, and proven in the real world.

For a deeper look at how our AI principles translate into real-world results, read Dr. Oscar Mendez’s “Real AI for Real Warehouses”.

At Locus Robotics, we’re leading the next era of intelligent automation where decisions move, warehouses learn, and AI delivers measurable performance at scale.

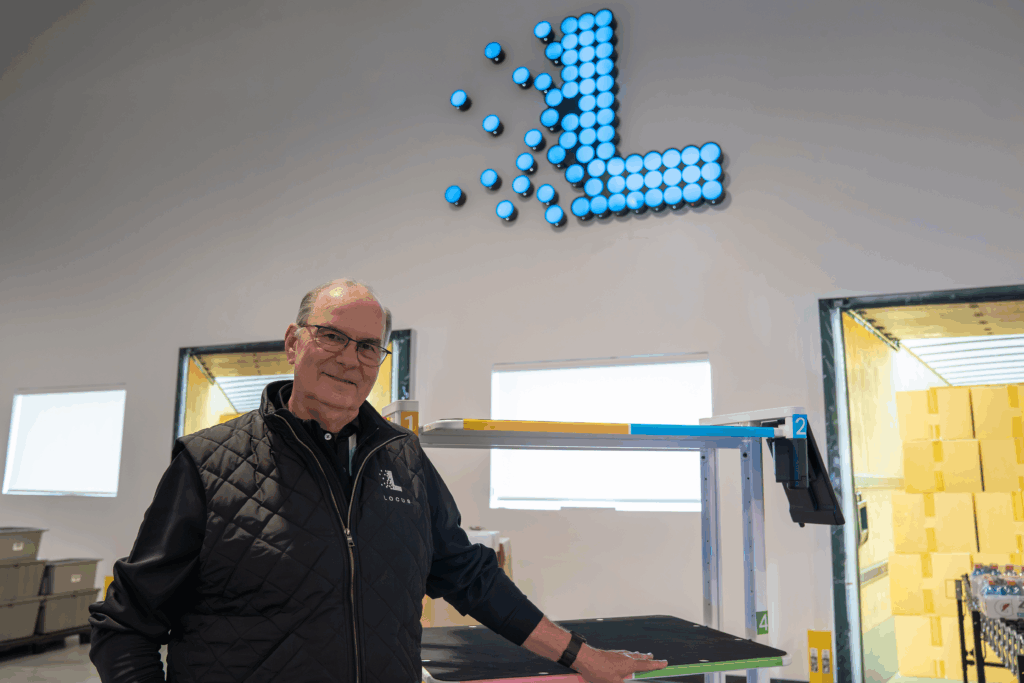

About the Author

Rick leads the executive team with over 30 years of experience in executive management, sales, and marketing for some of the world’s most successful technology companies, such as Cisco, Intronis, j2 Global, WebEx, Intranets.com, Barracuda Networks, Lotus Development, Mzinga, and PictureTel. Rick leads the executive team and is responsible for the overall strategy and execution at Locus Robotics. Rick currently sits on various boards and is an advisor to multiple companies, including Retrocausal, Arccos, Cybernetix Ventures, and Leading Edge Ventures. Past board positions include Yodle, Virtual Computer, Bidding for Good, Skill Survey, Influitive, Ntirety, Blue Raven, and Centive.