WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Avoiding the Warehouse Density Trap: Why Flexibility Beats Maximum Storage

Zaven "Zavo" Gabriel, Sr. Product Marketing Manager

Pressure is the constant every warehouse leader knows too well: SKUs multiply, SLAs tighten, and labor gets scarcer and more expensive. At the same time, demand can spike without warning, moving sideways as often as it climbs. When the system hits its limit, the reflex is always the same to hire temps, approve overtime, and hope the wheels stay on. It’s reactive, expensive, and unsustainable.

But the real risk isn’t the labor crunch or unpredictable demand. Instead, it’s what so many operations fall into when trying to solve them, which is the Density Trap.

The Density Trap, Defined

The Density Trap is the idea that more storage equals better performance and that if you can pack more SKUs, totes, and inventory into the same footprint, you’re winning.

It’s a trap.

Fixed systems, whether grid storage, ASRS, or Goods-to-Person (G2P) architectures, optimize for density first. And what they achieve is impressive, but the more tightly you pack the system, the less room it has to flex. The moment your operation needs to change, that density becomes a constraint.

Do the math. You might have 170,000 totes stored neatly inside a grid, but if you only have 34 pick stations feeding outbound orders, you’re functionally accessing just 0.02% of your inventory at any given moment. The other 99.98%? Is technically “in the system,” but practically out of reach when you need it most.

If you’re running tight cutoffs, medical SKUs, or peak volumes that spike without notice, that isn’t just inconvenient. In situations like that, the lack of availability can be a deal-breaker.

Fixed Systems, Hard Limits

Overfitting storage density strangles availability and bottlenecks throughput.

Throughput in a fixed system architecture is fundamentally capped. It’s unavoidable that the maximum output will never exceed the rate of a single station, multiplied by the number of stations. Once you hit that ceiling, you’re out of road and when volumes shift, when priorities change, and when SKUs turn over, the system is stuck.

When that rigidity compounds, you overbuild to account for peak throughput (“build the church for Easter Sunday”), underperform off-peak, and spend the rest of the year paying for both. For warehouse operators, that cost shows up in missed SLAs and idle labor. For execs, it’s stranded CapEx and brittle scaling.

A flexible system breaks that ceiling, since you add capacity where and when you need it. With intelligent orchestration, throughput becomes elastic. It’s not limited by fixed nodes, but scalable by design.

What We Built Instead

Maximizing storage isn’t the goal of a fulfillment operation. Fulfillment is. Storing more stuff in the same footprint is great, but it’s only worth doing to the extent that it helps you get orders out the door as efficiently as possible.

At Locus, we made a deliberate choice to avoid the Density Trap by optimizing for flow and not just storage. When we designed the LocusONE™ platform, we didn’t optimize for cramming the most totes into the tightest space. We optimized for flexibility and flow with how many orders you can get out, how quickly, how predictably, and how easily the whole system can adapt when conditions change. Because conditions will change.

Through LocusONE™, the robot fleet — Origin, Vector, Array, or any combination of the three — works as a single orchestrated system. They give you capacity where you need it, when you need it. They’re not bolted to the floor, and the system doesn’t lock you into one process or layout. The workflows adapt as your SKUs, volumes, and priorities evolve, so you can start small with one zone or one workflow, then expand when and where it makes sense, without construction projects or guesswork. When your needs change, your system flexes with you.

And when peak hits, the same fleet breathes with demand, avoiding the bottlenecks baked into rigid architectures. No more waiting for storage you can’t reach.

Let Go of the Wrong Metric

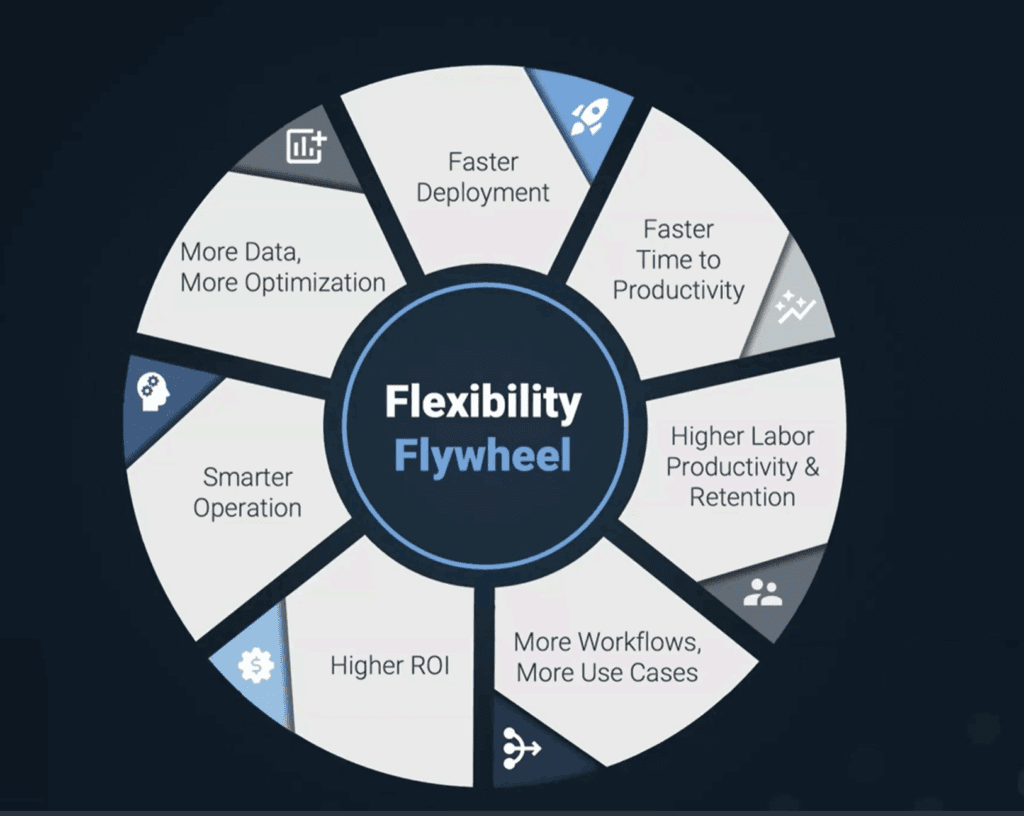

Storage density is easy to measure, but it’s also easy to get wrong. Because storage ≠ flexibility, and flexibility is what drives fulfillment.

We’ve seen it firsthand in customers:

- Scaling without construction

- Hitting record UPH on day one

- Tripling their fleet for peak season in the same building

- Cutting training time from weeks to minutes

- Cutting staff turnover to single digits

All because the system moved with them.

The Bottom Line

If your fulfillment system can’t flex, your business can’t scale, and no amount of extra storage will fix that.

That’s why we built LocusONE™ for flexibility on purpose to help you move, adapt, and scale without limits.

Avoid the density trap and design for flow to make fulfillment a competitive advantage, not a constraint.

Flexibility and throughput aren’t opposites. With the right system, you get both, and that’s the Locus difference.

Let’s talk about how to stay fast and keep scaling, even when the plan changes.