WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Why Flexible Automation Is Winning and What Comes Next

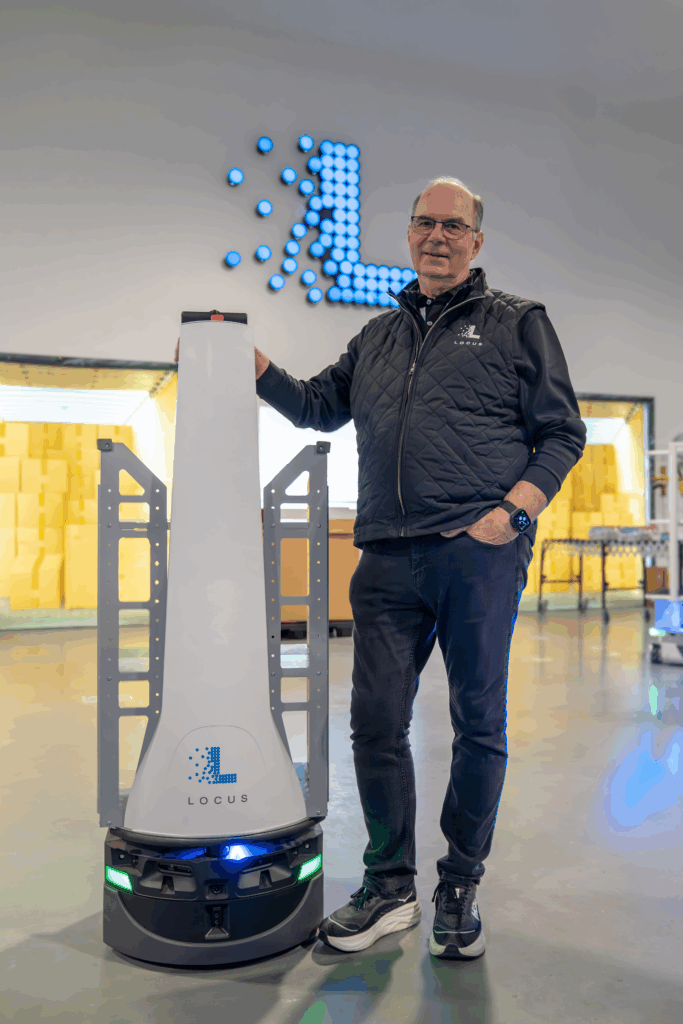

Rick Faulk, Chief Executive Officer

The 2025 Future of Warehouse Automation report from STIQ is a timely and insightful look into the evolving warehouse landscape and it captures a reality that every supply chain leader knows firsthand. Static, fixed warehouse systems no longer cut it when it comes to your warehouse operations. Instead, agility, scalability, and rapid deployment for warehouse automation are true business requirements.

One of the most important takeaways from the report is the sharp rise in flexible Person-to-Goods (P2G) systems, the emergence of Robots-to-Goods (R2G) fulfillment, and the growing importance of AI-based System-Directed Labor (SDL), which STIQ refers to as Software-Directed Labor. These trends are redefining fulfillment, and they’re exactly where the Locus solution suite is focused.

Flexibility and Scalability: The Defining Trend

Right out of the gate, STIQ names flexibility and scalability as the “major leading trend in the warehouse automation sector.” That’s not a surprise to us, as these qualities are foundational to everything we’ve built, from our fleet of autonomous mobile robots (AMRs) to the intelligence behind LocusONE™, our orchestration platform.

Flexibility means your automation can adapt to your business, and scalability means you can grow without needing to re-architect your infrastructure. The Locus solution suite delivers both, and the market is demanding it more than ever.

P2G 3.0 and the Future of Modular Fulfillment

STIQ defines the current era as “G2P/P2G 3.0,” a phase marked by modular, best-of-breed systems working in concert to support flexible and scalable fulfillment. Gone are the days of monolithic infrastructure; the warehouses thriving today are those that deploy automation that adapts, integrates, and grows as business needs change.

At Locus Robotics, that’s exactly what we’ve engineered into LocusONE™, our intelligent orchestration platform that unifies a fleet of specialized autonomous robots:

- Locus Origin handles high-throughput, associate-directed P2G workflows.

- Locus Vector expands these capabilities to heavier payloads and multi-zone operations, without requiring fixed infrastructure.

Together, they enable fulfillment teams to respond in real time to volume surges, labor variability, and changing order profiles.

The R2G Shift and the Rise of Array

STIQ makes another important distinction: for the first time, Robots-to-Goods (R2G) is named and defined as a standalone category of automation. This marks a strategic turning point in how the market views robotic collaboration, and it validates our strategy to lead the next wave of innovation.

Previewed at ProMat 2025, Locus Array is our answer to that shift. Purpose-built for compound mobile fulfillment, Array enables inter-robot collaboration and high-volume payload handoffs without the need for fixed infrastructure. It’s designed for warehouses that want to move beyond traditional P2G and into a zero-touch, total warehouse automation model.

System-Directed Labor: AI in Motion

STIQ also underscores the growing importance of Software Directed Labor (SDL), which we refer to as System-Directed Labor, as a critical enabler of AI-driven warehouse optimization. With LocusONE™, customers are putting SDL into practice to dynamically assign tasks based on priority, location, and throughput goals to balance human and robotic labor in real time.

The impact on warehouse productivity and operations is tangible as System-Directed Labor removes guesswork from the floor and gives associates clear direction. Instead of waiting at pack stations or competing for robots, pickers stay in motion to boost productivity, reduce physical strain, and hit targets with less fatigue.

In our early deployments, SDL has delivered very measurable gains, and we’ve seen a productivity uplift and fewer FTE hours required per line picked.

This is AI in motion that is practical, proven, flexible, and ready to scale. By connecting the Locus Optimization Engine with real-time orchestration, customers can confidently staff their operations for peak performance, knowing each worker and robot is moving with purpose. As one Industrial Engineer put it, “Associates are on a mission to reach their next robot and move with a purpose.” The result in the warehouse is faster speed to competency, a more accountable workforce, and a floor that stays agile even as demands shift.

Data and AI: The Next Competitive Advantage

Beyond hardware, STIQ highlights how data and AI are becoming strategic enablers of warehouse performance. At Locus, we’re actively investing in Physical AI and real-time analytics to help our customers optimize everything from labor allocation to replenishment cycles.

When automation systems become connected AND predictive, warehouses unlock a new level of agility and efficiency.

RaaS: Built for Agility

Another major theme STIQ calls out is the rising adoption of Robots-as-a-Service (RaaS), particularly for 3PLs and asset-light operators. Locus has been a pioneer in this model, offering the ability to deploy automation quickly, scale on demand, and align costs directly with operational output.

The benefits of RaaS are real and include:

- Faster time to value

- Minimal capital expenditure

- Flexibility to grow without long-term lock-in

In volatile environments, this flexibility is essential.

The Future Is Mobile, Modular, and Intelligent

As STIQ makes clear, warehouses are fast becoming factories of the future, and that future requires systems that are modular, interoperable, and deeply intelligent. From P2G to R2G, from SDL to RaaS, and from tactical deployments to data-driven strategy, Locus is already helping customers deliver on what’s next.

About the Author

Rick leads the executive team with over 30 years of experience in executive management, sales, and marketing for some of the world’s most successful technology companies, such as Cisco, Intronis, j2 Global, WebEx, Intranets.com, Barracuda Networks, Lotus Development, Mzinga, and PictureTel. Rick leads the executive team and is responsible for the overall strategy and execution at Locus Robotics. Rick currently sits on various boards and is an advisor to multiple companies, including Retrocausal, Arccos, Cybernetix Ventures, and Leading Edge Ventures. Past board positions include Yodle, Virtual Computer, Bidding for Good, Skill Survey, Influitive, Ntirety, Blue Raven, and Centive.