WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Smarter Packaging, Stronger Operations: A Step-by-Step Guide to Getting Started

Mary Hart, Sr. Content Marketing Manager

Warehouses looking to automate often focus on upstream processes like picking and inventory movement. But there’s an overlooked opportunity that can drive big returns fast: packaging.

In my recent conversation with Bryan Boatner, Global Managing Director of Automation at Ranpak, on the “Warehouse Automation Matters” podcast, we explored how to use packaging as an entry point into warehouse automation. One key point is that packaging is a high-impact area for driving efficiency, reducing costs, and creating a better end-user experience.

Here’s a practical, step-by-step guide based on Bryan’s expert advice:

Start at the End of the Line with Packaging

Packaging is the final touchpoint in your fulfillment process, which makes it a smart and often lower-risk place to begin automation. Automating packaging tasks, like carton forming, void fill, and sealing, can immediately streamline repetitive work, reduce labor dependency, and improve throughput.

Unlike upstream automation projects, end-of-line automation doesn’t interfere with inventory management or picking logic, which means it can be implemented with minimal disruption. It also creates downstream visibility into bottlenecks and helps reveal inefficiencies upstream.

Focus on Right-Sized Packaging

Replacing one-size-fits-all boxes with right-sized cartons delivers measurable gains:

- Reduce material usage and waste by eliminating unnecessary filler

- Lower freight and dimensional shipping costs by optimizing each package's footprint

- Improve the customer experience by creating a more intentional and branded unboxing moment

Right-sized packaging also supports sustainability goals by using fewer raw materials and reducing the carbon footprint of each shipment.

Eliminate Waste Holistically

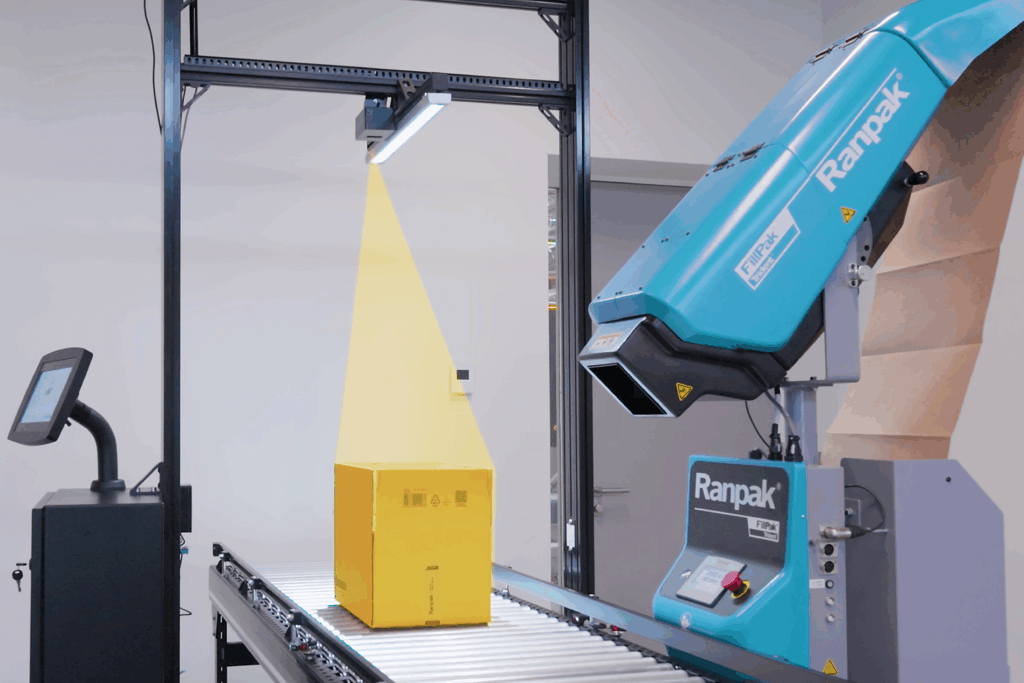

Automation saves materials and improves the entire packing workflow. From robotic carton forming (like Ranpak’s Form’it!) to intelligent void-fill systems (like FillPak Trident with Decision Tower), modern automation cuts waste on multiple levels:

- Reduces pack time through streamlined, repeatable processes

- Improves ergonomics by minimizing manual material handling

- Decreases damage and returns by ensuring secure, custom-fit packing

These systems also enable greater process control, helping warehouses ensure that each order meets quality standards without relying solely on manual checks.

Leverage Data, Even If It Isn’t Perfect

Many warehouse operators hesitate to adopt automation because of imperfect product data. But Boatner emphasized that today’s smart systems are built to adapt in real time.

Ranpak’s Decision Tower, for example, uses machine vision to scan the contents of a carton and dispense precisely the right amount of recyclable paper fill, regardless of the accuracy of SKU dimensions in the WMS. That ability to operate effectively in less-than-perfect data environments is a game changer for busy fulfillment centers.

Track the Right KPIs

Measuring ROI requires the right metrics. Boatner recommended starting with:

- Labor reallocation and utilization

- Throughput rates per pack station

- Shipping volume reduction (due to right-sized cartons)

- Packaging material usage

- Damage and return rates

- Customer feedback on packaging and unboxing

Together, these KPIs offer a more complete view of the value packaging automation brings.

Choose Modular, Scalable Solutions

One of the most practical points Boatner shared is that you don’t need to automate everything at once. Start with modular systems that can scale as your business grows. Whether you begin with a single void-fill station or a full end-of-line solution, the ability to add capabilities without a full rebuild is essential.

Also, don’t overlook maintenance and look for systems your in-house teams can support with minimal outside intervention. Ranpak’s equipment, for instance, is designed to be user-friendly and serviceable, reducing long-term support costs and improving system uptime.

Make Packaging Part of Your Strategy

If packaging hasn’t been part of your automation roadmap yet, it might be time to take a closer look. As Boatner pointed out, packaging is one of the most consistent and repetitive workflows in a warehouse and that makes it one of the ripest for automation.

Want more expert advice? Listen to the full “Warehouse Automation Matters” episode featuring Bryan Boatner.