WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

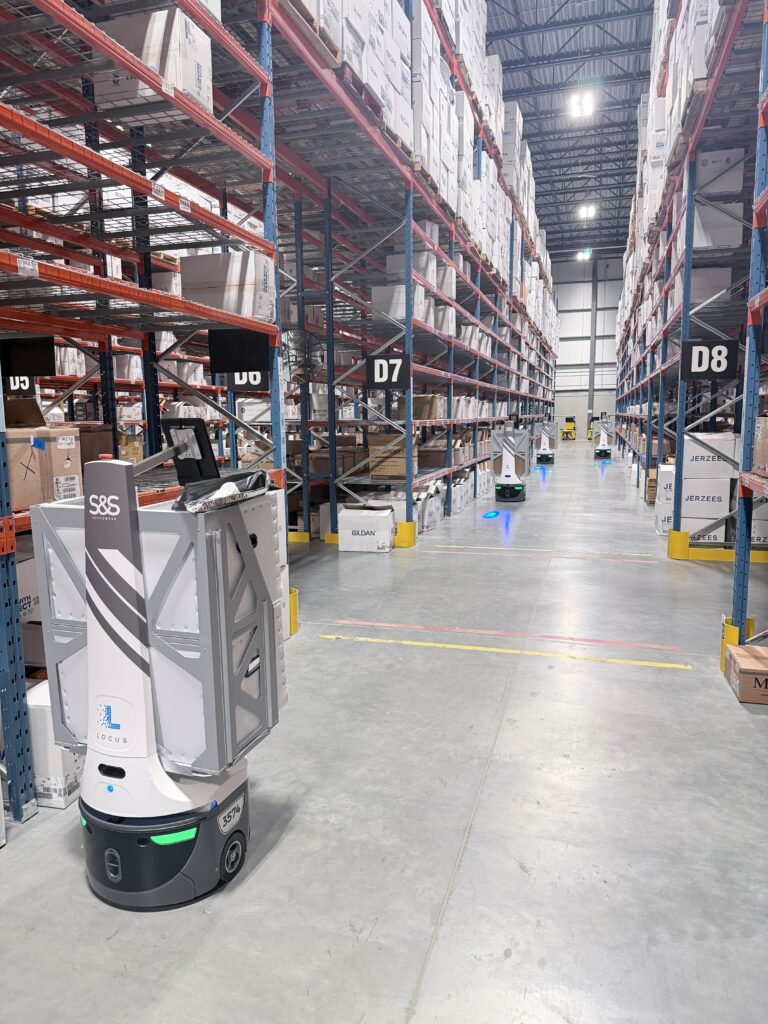

How S&S Activewear Scaled Smarter with Warehouse Robots

Mary Hart, Sr. Content Marketing Manager

When growth outpaces your floor, even the best operations teams feel the strain. For S&S Activewear, a leading distributor of imprintable apparel and accessories with 18 distribution centers across North America, the challenge was how to keep up with rising demand without overextending their workforce.

“We were growing quickly, but it just wasn’t sustainable to keep adding more employees,” said Cole Lohman, Director of Automation at S&S Activewear. “We needed a technology solution that could help our productivity.”

That solution arrived with the 2024 acquisition of alphabroder, a company that was already thriving with Locus Robotics. The success Lohman’s team saw with warehouse automation made the next step clear that it was time to bring robotics to S&S.

From Stock Chasers to Smart Zones

Before automation, S&S relied on stock chasers and batch picking to send associates across the floor to fulfill orders. Associates that used the stock chasers needed to be certified, which typically took 2 days to complete, but then there was an additional 2 to 3 months of time for the driver to feel comfortable and proficient.

“Users were picking from one side of the building to the other,” recalled James Hillier, Regional Director of Operations at S&S Canada. “It took a long time to finish everything.”

The shift to automation was immediate. “It was magic,” said Randy Hazelwood, Shipping Supervisor at S&S Canada. “With Locus coming in, it was a fast changeover.”

The team transitioned to zone picking, where associates stayed in defined areas while Locus Robots moved orders between zones. “That’s enabled our teams to travel less and pick more,” Hillier said. The result was a 25% improvement in throughput and a jump from 48 lines per hour to 70–75 lines per hour.

Even more telling, the Vaughan, Ontario site now holds the top productivity ranking across the S&S network after just three months of running Locus Robotics.

A Lesson in Speed and Simplicity

S&S’s first Locus deployment met and exceeded their expectations.

“Our integration took only 49 days from green light to go-live,” said Mitchell Bluford, Sales Executive at Locus Robotics. “That’s one of the fastest we’ve ever seen.”

The implementation itself was remarkably smooth. “Bringing on new technologies can be challenging at times,” Lohman said. “This one was a little bit boring as it went as expected, with no real stressors at all.”

The facility didn’t need to change its layout or retrain the team from scratch. “The robots worked within our existing warehouse,” Lohman explained. “Locus made the integration incredibly easy.”

That ease translated into real workforce benefits. “The intuitive interface cut training time in half,” Lohman continued. “Stock chaser certification could take up to three months before and now our new associates are productive in days.”

Breaking Records and Building Balance

Warehouse automation quickly changed more than just metrics at S&S Activewear. “We completed and shipped 23,000 lines in one day,” Hillier shared. “After Canada Day, we even hit an hour with over 3,000 lines shipped.”

During their busiest week of 2025, the team fulfilled over 100,000 lines, without the long shifts that used to define peak season. “Last year, we would have been working 12- to 14-hour days,” Hillier said. “Now we’re finishing in eight to nine hours, and people are getting more balance at home.”

For S&S associates, that shift has been tangible. “It’s so efficient that we finish on time no matter how much work there is,” Hazelwood said. “Making customers happy is our top priority, and the system makes that easy.”

The ergonomic gains were just as important. “Working with the robots is less strenuous,” said Benjamin DePrisco, Safety Specialist. “It’s a lot better ergonomically, and we’ve seen a reduction in ergonomic reports compared to when we used stock chasers.”

A Data-Driven Path to Continuous Improvement

Beyond productivity, S&S uses the LocusHub platform to fine-tune performance. “We’re matching how we staff and position our employees to the capabilities of the robots,” Lohman said. “Locus provides a lot of good data to see how efficient we’re being.”

Hillier agrees: “LocusHub reporting is very intuitive. There are so many ways to use it to help run your business.”

That focus on continuous improvement is paying off fast. “We’re building toward hitting our ROI in a very short amount of time,” Lohman said. “And Locus has been a great partner that is very supportive of ongoing improvements.”

Today, S&S runs Locus Robots in 10 facilities across the U.S. and Canada, with four more in the pipeline. The company continues to expand both its automation footprint and its data-driven mindset to scale smarter, not harder.

For S&S Activewear, automation has meant more than efficiency gains. It means balance for associates, consistency for customers, and scalability for the business.

“We’ve set records for productivity, and we’re still improving,” said Bluford. “That’s what makes this partnership special — it doesn’t end at go-live.”