WP: How to achieve 400 UPH with Locus Fast Pick

How Beauty & Personal Care Warehouse Automation Solves Fulfillment Challenges

Success in beauty distribution requires speed, consistency, and careful handling. High SKU counts, fragile packaging, shade and batch accuracy, and omnichannel expectations place intense pressure on warehouse workflows.

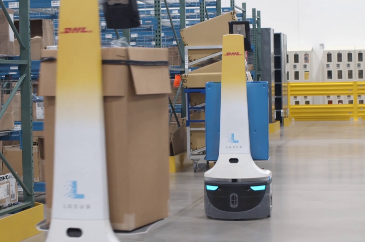

Locus Robotics helps operators match that pace with automation that adapts to your products, people, and processes — not the other way around.

View the DHL Makro Case Study