See how KSP Fulfillment hit 10 million robotic picks with automation strategies for labor stability, accuracy, scalability, and ROI that 3PLs can replicate.

Discover how KSP Fulfillment achieved 10 million robotic picks, stabilizing labor, scaling operations with RaaS, and shaping the future of 3PL automation and customer trust.

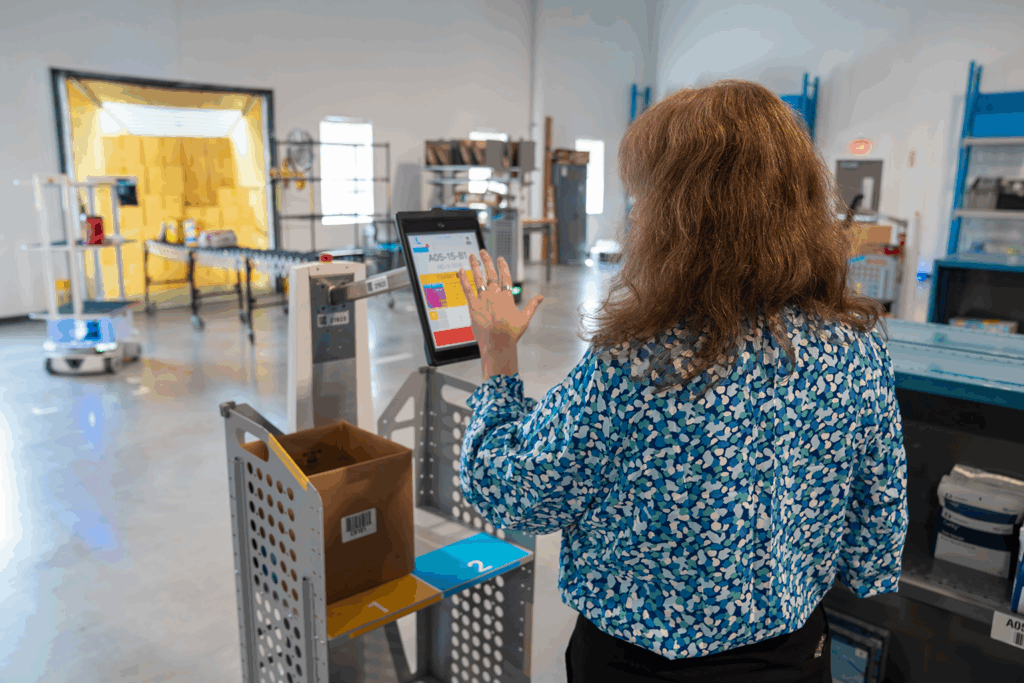

Learn how warehouse automation improves human work by reducing strain, speeding training, boosting safety, and enhancing inclusion.

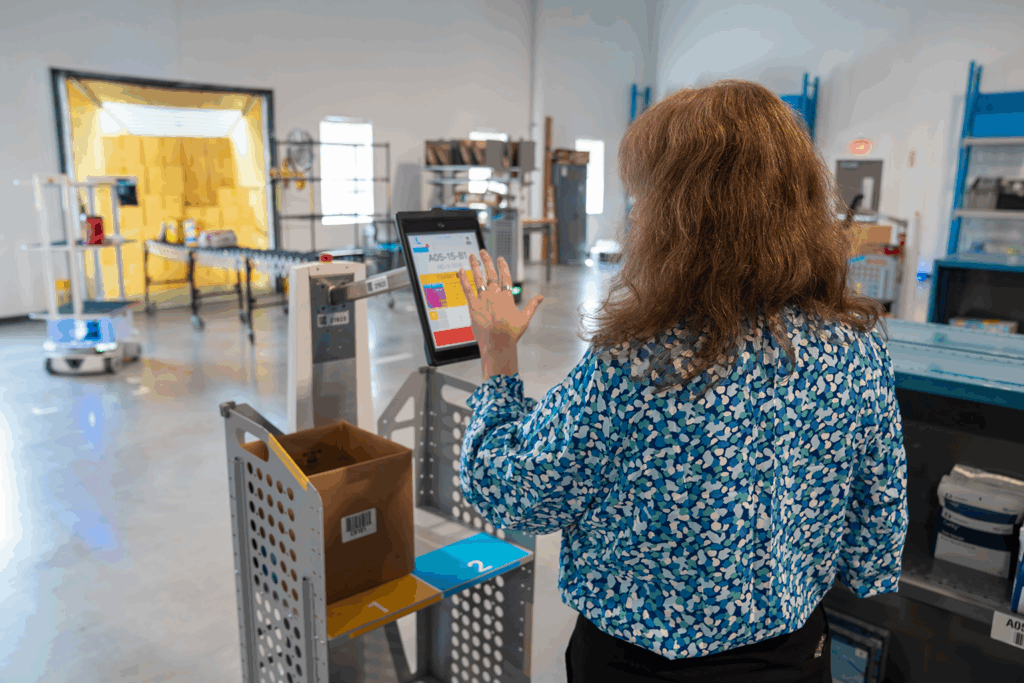

Discover how warehouse leaders balance automation with the human touch by prioritizing continuous improvement, communication, and flexibility to enhance employee experience and customer outcomes.

Explore the human side of warehouse automation as Tony Altman shares how flexibility, improvement, and trust drive technology adoption that benefits customers and employees.

Low-code platforms give warehouse managers flexibility to adapt systems, integrate automation, and boost efficiency without long dev cycles. Learn practical steps from Datex experts in this playbook-style guide.

Discover practical ways to apply AI in your warehouse with expert insights from Oscar Mendez, focusing on real ROI, physical AI, and step-by-step implementation strategies.

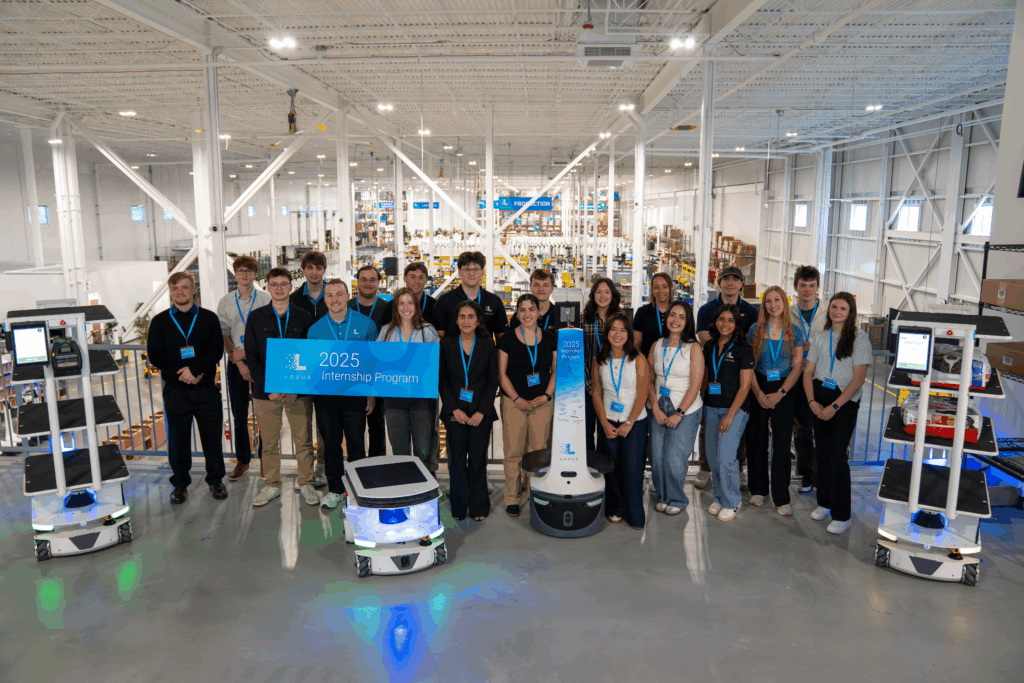

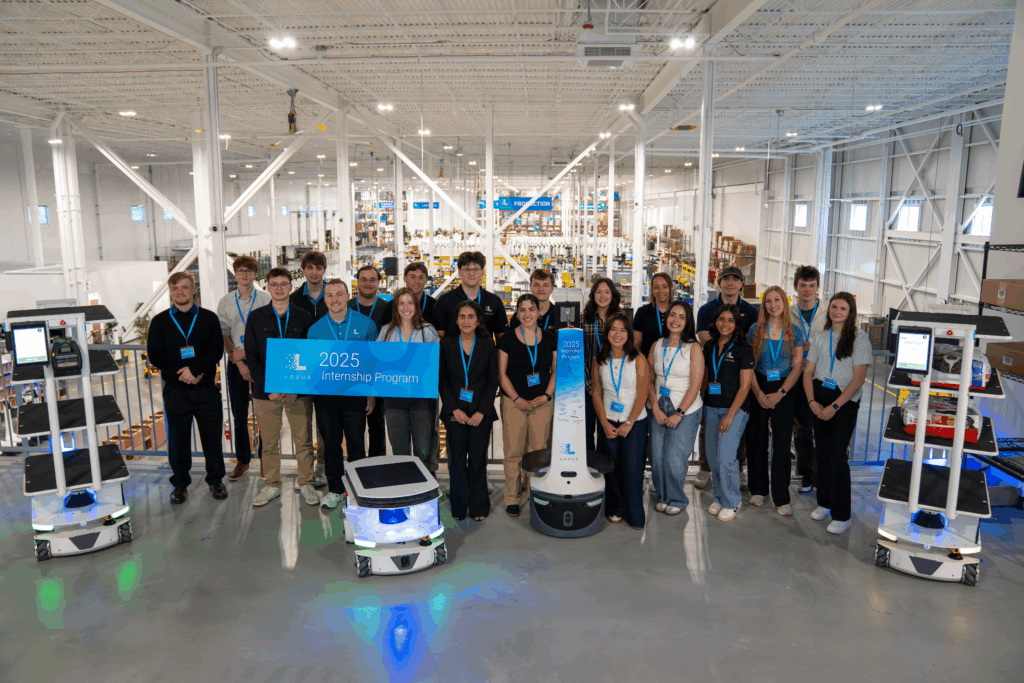

Discover how Locus Robotics’ summer internship program empowered interns across departments to innovate, collaborate, and grow through real-world projects, mentorship, and a supportive, engaging workplace culture.

Prepare your warehouse for peak season with year-round planning, volume modeling, simplified training, and AMR support. Practical steps to boost throughput, protect teams, and meet SLAs with flexibility.

Discover how low-code platforms like Datex Studio help warehouses modernize WMS, boost flexibility, and integrate automation to drive ROI, adaptability, and competitive advantage in complex fulfillment environments.

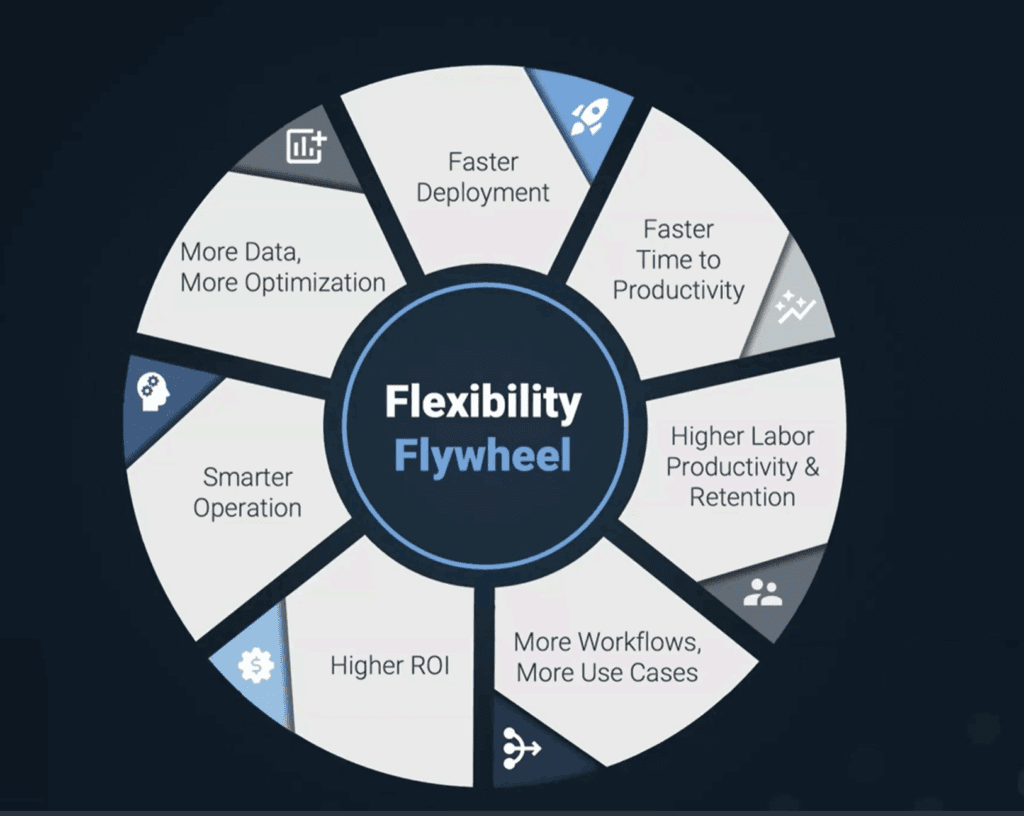

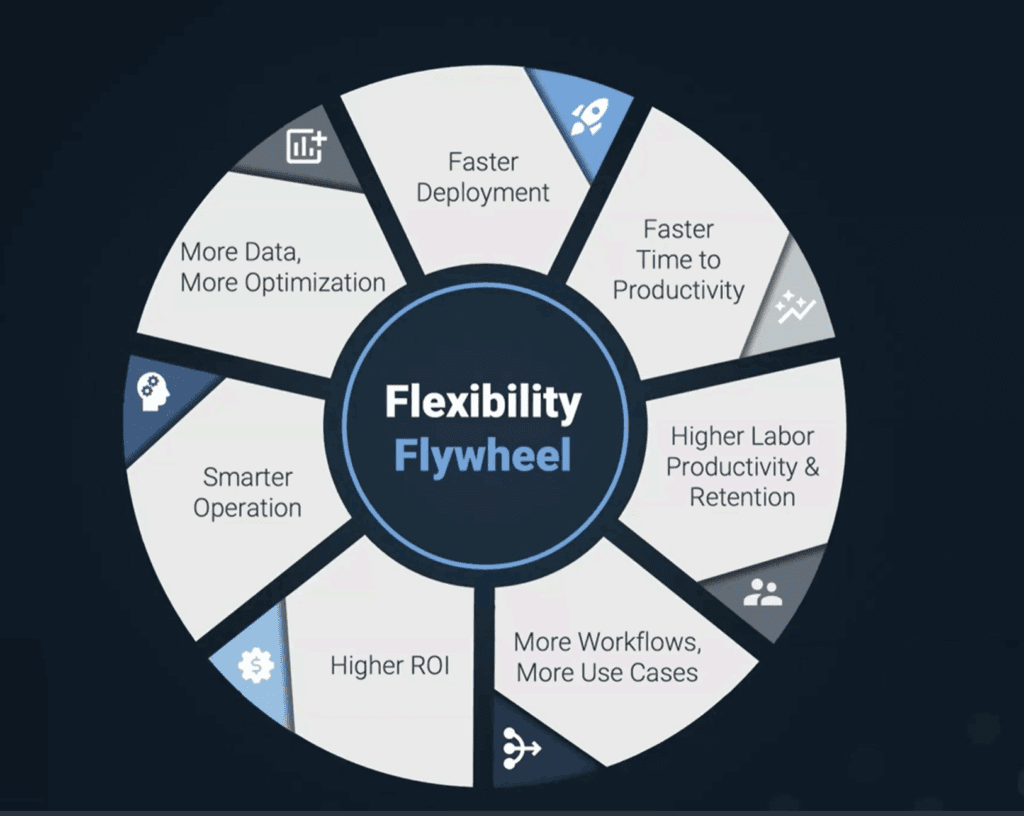

Discover why optimizing for flexibility, and not storage density, is key to scaling warehouse fulfillment and avoiding throughput bottlenecks in rigid systems.

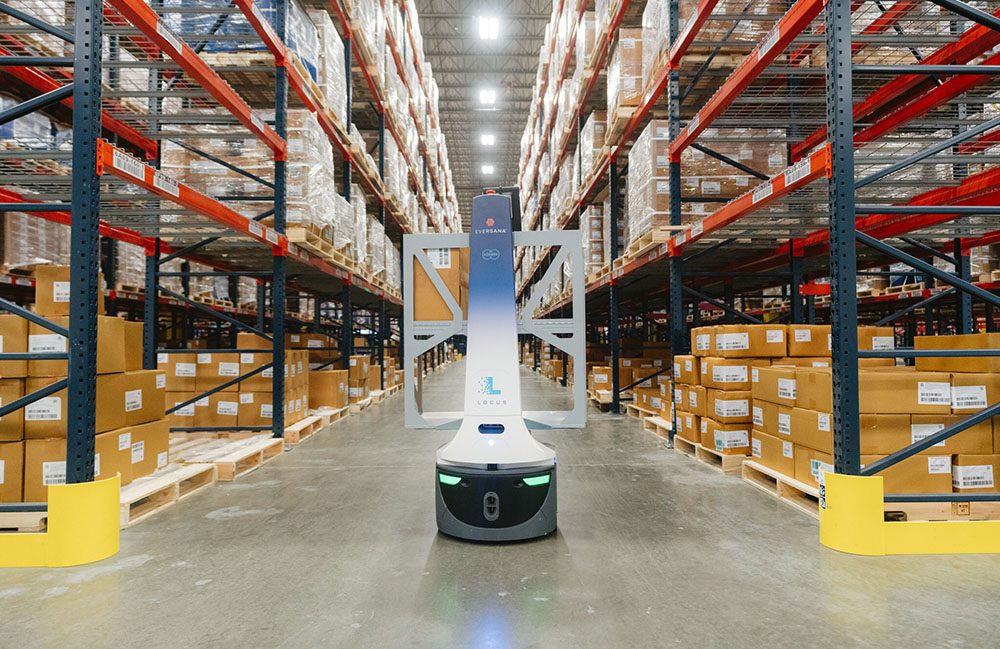

Explore how Locus Robotics builds real-world AI for warehouses that boosts throughput, reduces labor, and earns warehouse managers’ trust from day one.

Discover the essential WMS features for automation-driven warehouses, from real-time orchestration to robotics integration, that help operations scale, optimize labor, and meet omnichannel and same-day delivery demands.

Discover a step-by-step playbook for selecting the right WMS. Learn how to align teams, fix process gaps, and choose a system that scales with your warehouse and automation goals.

Learn key warehouse automation terms, from AMRs and R2G to UPH and system-directed labor, to align teams, evaluate vendors, and scale smarter. A must-have glossary for warehouse leaders.

Discover what really matters when choosing a Warehouse Management System. Learn why inventory accuracy, scalability, and usability outweigh features and how Made4net supports flexible, real-time warehouse operations.

Learn how Staples Canada began its warehouse automation journey by prioritizing systems, goals, and collaboration. This step-by-step playbook helps you start smart with the right WMS, partners, and KPIs.

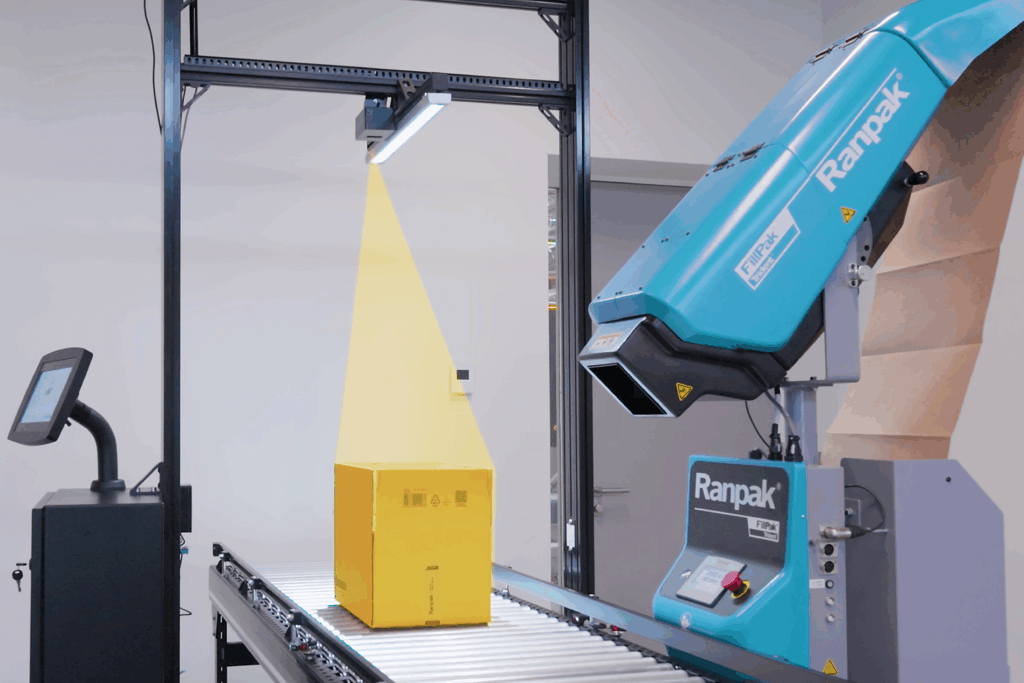

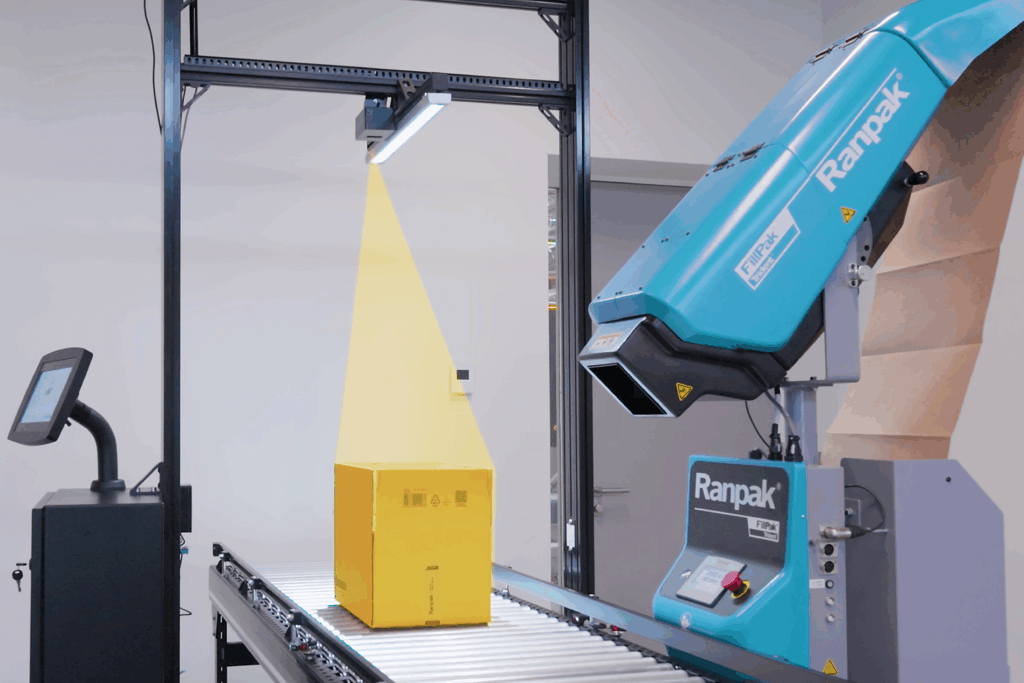

Discover how smarter packaging can kickstart warehouse automation. This step-by-step guide explains how to reduce costs, cut waste, and boost efficiency with modular, right-sized packaging solutions.

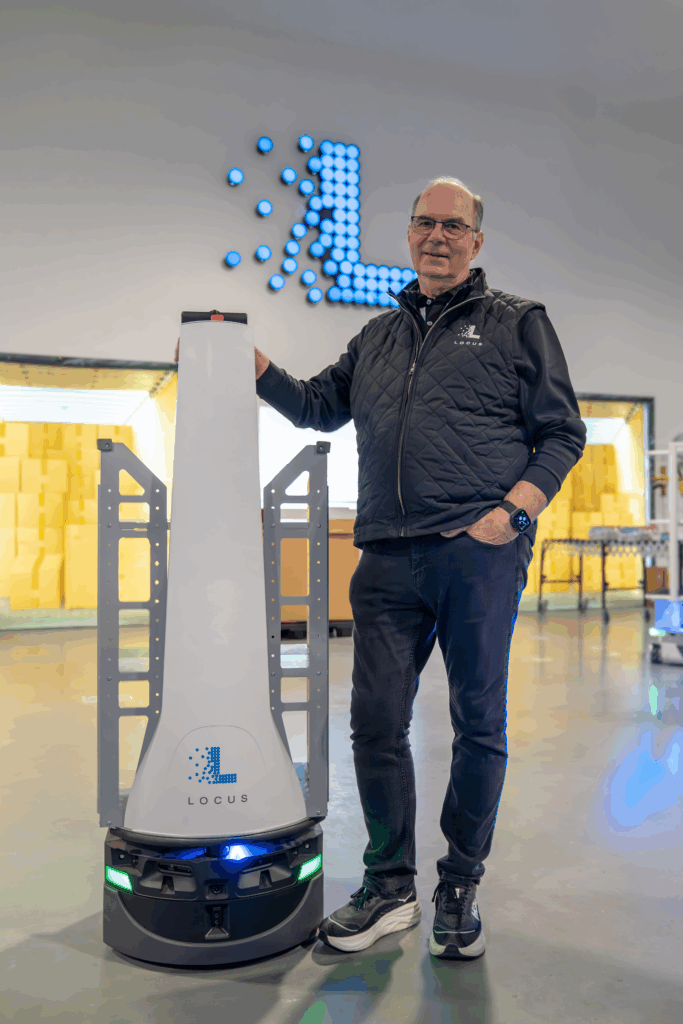

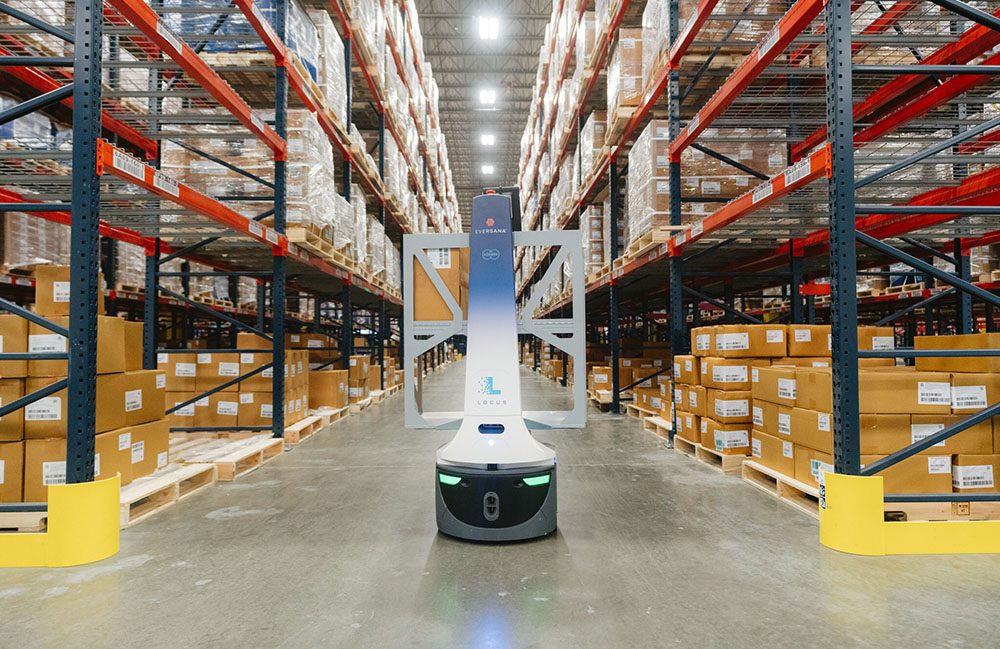

Discover why flexible automation is reshaping warehouses. CEO Rick Faulk explains trends like P2G, R2G, System-Directed Labor, and RaaS, and how Locus Robotics is driving the next evolution.

Discover how smarter, right-sized packaging can boost warehouse efficiency, reduce waste, and free up labor.

Recruiting scams are on the rise, and getting smarter. Learn how to spot red flags, protect your personal data, and ensure any job offer is legitimate in this must-read guide.

Discover how Staples Canada transitioned from manual processes to automation with robots. Learn how cross-functional teamwork, data-driven design, and a people-first mindset powered their successful warehouse transformation.

Learn how to choose the right warehouse automation solution by aligning technology with business goals. Explore strategies for flexibility, ROI, and long-term scalability, plus a real-world success story.

Learn how to choose the right 3PL partner for your retail brand. This playbook outlines key criteria of tech, automation, onboarding, and scalability to help e-commerce leaders grow smarter and faster.

Discover why warehouse leaders consistently recommend Locus Robotics. Explore our latest global NPS results and hear directly from customers about what makes our automation partnerships reliable, responsive, and results-driven.

LocusLABS turns advanced robotics ideas into scalable solutions and boosts warehouse efficiency with AI-powered navigation, real-time labor coordination, and simulation-driven optimization that’s built and tested in real customer environments.

See why live demos and peer insights are essential when evaluating warehouse automation. Discover how Locus Insights Day helps leaders validate solutions in real-world environments before making critical decisions.

Fast-growing brands need 3PLs that go beyond fulfillment. Discover what to look for in a logistics partner, from automation and tech integration to true collaboration.

Locus CEO Rick Faulk reflects on nine years of growth, the core strategies behind scaling automation, and nine bold predictions for the future of AI-powered warehouse operations and robotics.

Discover how packaging automation drives warehouse efficiency, cost savings, and sustainability. Learn how smart right-sizing, void fill, and sealing systems reduce waste, labor, and carbon footprint.

Discover how Staci Americas uses warehouse automation to scale beauty fulfillment with precision, ensure compliance, protect fragile products, and maintain quality from packout to delivery.

Humanoid robots are grabbing headlines, but purpose-built warehouse automation delivers results now. Discover why physical AI is the real future of logistics.

Discover how flexible automation helps warehouses adapt to shifting demand, labor shortages, and SKU volatility without falling into the density trap. Learn why flexibility is key to productivity and resilience.

Discover how Locus Array and Robots-to-Goods (R2G) automation enables 24/7 picking, faster deployment, and higher density to solve labor, flexibility, and throughput challenges in modern warehouse operations.

Learn about warehouse agility, flexible design strategies, real-world examples, and how to adapt to ongoing market and tech changes.

Discover how Locus Robotics’ RaaS model supports the circular economy, reduces warehouse waste, and extends product life while giving back through global donations of robotics tech and equipment.

Discover how to secure your warehouse automation strategy. Learn key steps for managing risks, protecting data, and building resilient, future-ready operations in an increasingly digital and connected environment.

Tariffs are disrupting supply chains and automation plans. Discover why flexible warehouse automation helps 3PLs and fulfillment leaders adapt quickly without major capital risk or steel-dependent infrastructure.

Flexible warehouse automation helps luxury fashion brands reduce costs, boost efficiency, and maintain high-touch service while adapting to seasonal shifts, resale trends, and omnichannel demands without sacrificing speed or personalization.