By downloading, you’ll explore the STRIDE framework, practical examples, and the importance of comprehensive risk analysis, equipping you with the knowledge needed to effectively safeguard your warehouse operations.

Fleet Feet partnered with Körber and Locus Robotics to implement autonomous mobile robots, boosting warehouse efficiency, speeding up training, and doubling order fulfillment.

In this episode, Mary Hart interviewed Drew Eubank and Jordan Frank of the Zion Solutions Group to discuss the future of warehouse automation.

In this episode, Mary Hart interviews Austin Feagins, Senior Director of Customer Solutions at Staci Americas, about how to prepare for a peak season in the warehousing industry.

Kevin Lawton, host of The New Warehouse podcast, discusses the major shifts in the warehouse and supply chain industry, including a shift from the idea of a fully automated warehouse to a focus on collaborative robotics and enabling workers to do more with less.

This eBook will explore case studies of large warehouses that have successfully automated their operations. These real-world examples will illustrate the benefits and practical steps involved in transitioning to an automated warehouse.

See how Locus Robotics is driving efficiency, productivity, and cost savings for businesses just like yours.

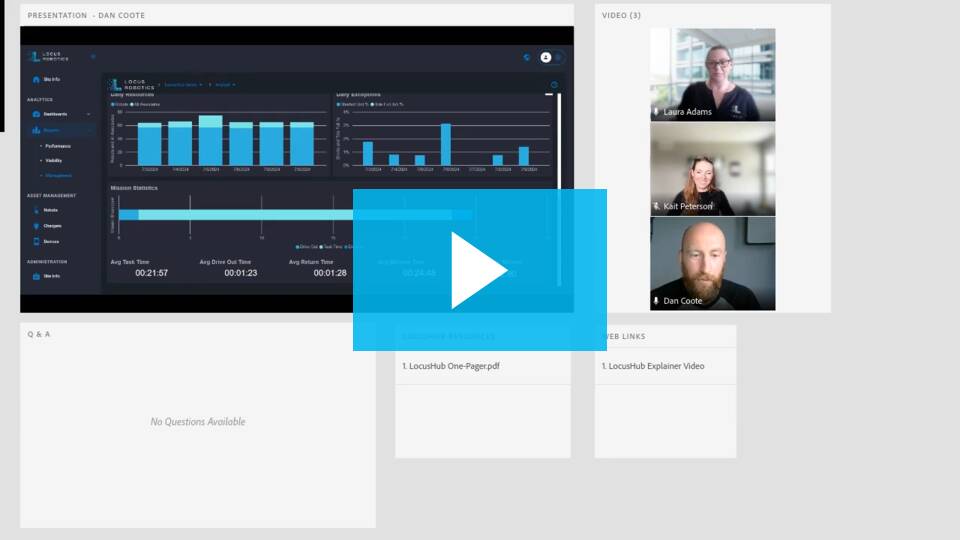

The webinar reviewed LocusHub reports, introduced the Analyst Report, and demonstrated key metrics analysis with timeline graphs.

Discover how pick velocity and innovative automation strategies can transform warehouse operations.

More than 80% of warehouses aren’t automated because they’re still using old, ineffective manual processes. Use this checklist to determine if your warehouse could be more efficient with automation.

More than 80% of warehouses aren’t automated because they’re still using old, ineffective manual processes. Use this checklist to determine if your warehouse could be more efficient with automation.

Anthony Pendola, Senior Manager of Distribution at Fleet Feet, and John Santagate, Senior Vice President of Robotics at Korber Supply Chain Software, talk about the benefits of humans and robots working together in a warehouse setting.

Thomas Stearman, the Director of Industrial Engineering at UPS, discusses the importance of pick velocity — how fast items can be picked and prepared for shipment. UPS has implemented strategies such as batch picking, warehouse execution systems, and automation technologies to improve pick velocity. These technologies have not only increased efficiency but also improved employee satisfaction and reduced turnover.

With over 180 locations and four million square meters of storage space, Rhenus Logistics faced a labor challenge in their Hörselgau facility. They implemented Locus Robotics on their mezzanine, which improved training time and increased productivity by over 50%. During peak season, Rhenus scaled up from 135 bots to 162 with the Robots-as-a-Service model. The partnership between Rhenus and Locus has been successful, and they are considering a solution for their level zero with Locus.

Kait Peterson, senior director of product marketing at Locus Robotics, claims person-to-goods (P2G) robotics outperforms goods-to-person (G2P) systems in warehouses. P2G involves workers collecting items for robots, offering flexibility and scalability for any facility size without major infrastructure changes, making it ideal for seamless automation.

Go! Retail uses LocusBots for both picking and putaway, after learning that the bots were dual-purpose. Larivee says, “We have the bots do both picking and putaway. They deliver empty totes for picking and full cases. With our previous system where we used push carts and hand scanners, putaway could take three to five hours. Now that we use Locus for putaway, our daily restock has sped up by about 40% in one day.”

Locus Robotics has spurred DHL Supply Chain to improve other areas of their building, from the conveyor line to improved packaging operations.

Making the move to a new greenfield warehouse and automating that facility demands a strategic and systematic approach. This checklist goes over the critical steps that you need to accomplish to ensure your automation strategy is accomplished with precision and delivers the intended benefits. By adhering to this checklist of best practices, you can anticipate a significant return on investment (ROI) and evade common obstacles that can impede progress.

Making the move to automation while staying in your current brownfield warehouse facility demands a strategic and systematic approach. This checklist goes over the critical steps that you need to accomplish to ensure your automation strategy is accomplished with precision and delivers the intended benefits. By adhering to this checklist of best practices, you can anticipate a significant return on investment (roi) and evade common obstacles that can impede progress.

Find out how to navigate your retail warehouse automation options and find the right technology to streamline your operations without a complete overhaul.

The demand for flexible, scalable solutions that create efficiency and productivity in your warehouse has never been more critical.

Download this on-demand webinar to learn the top benefits of Persons-to-Goods (P2G) over Goods-to-Person (G2P) warehouse automation, including:

* Streamlined operations

* Boosted productivity

* Improved accuracy

* Increased employee retention

Whether you’re grappling with fluctuating order volumes, seeking to reduce labor costs, or aiming to enhance your team’s efficiency, our Senior Director of Product Marketing, Kait Peterson will illuminate the path to achieving these goals through the strategic adoption of P2G warehouse automation.

Learn the reasons why prioritizing pick velocity over storage density can significantly boost warehouse efficiency, meet customer demands for rapid delivery, and enhance overall operational productivity.

Home Case Study Warehouse Efficiency Soars at Premier® Yarns with […]

See how Concordance Healthcare Solutions transformed distribution with Locus Robotics, boosting efficiency and employee retention.

The GEODIS team decided to use autonomous mobile robots (AMRs) to optimize logistics operations in the warehouse and chose Locus Robotics as their vendor. GEODIS integrated 12 Locus Vector with Cart AMRs across a 40,000 square feet picking area. The Vector AMRs are unique — they can attach and handle carts, allowing for the transportation of heavier products and increasing the throughput of orders per mission.”

Home Video Rhenus – Higher LPH Mezzanine Picking Rhenus, a […]

Every warehouse has a boogeyman and for many managers, it’s automation. They picture giant scary robots gobbling up jobs, crushing workers, and wreaking all kinds of havoc. But most automation fears are as light as a feather, not stiff as a board. Allow me to bust the top 9 warehouse automation fears with some cold, hard facts.

Home 3PL Case Study Bluegrass Supply Chain View The Case […]

Discover the top challenges faced by warehouse managers and how robotic automation can alleviate these pressures.

Discover the built-in safety features of AMRs for seamless human-robot collaboration.

Learn how our robots can excel in both ambient and refrigerated cold storage warehouses to help improve productivity.

Robots don’t replace jobs — instead, they pave the way for increased employee morale plus associate upskilling and career growth.

Learn how AMRs give your warehouse the flexibility to thrive during peak season.

Explore how to optimize workflows, accelerate deployment, and build in flexibility from day one with greenfield facility warehouse robots and automation.

Learn how robots give brownfield warehouses an easy, cost-effective way to upgrade operations, reduce costs, improve productivity, and scale flexibly.

Home 3PL Case Study Amware Download the Case Study “Having […]

Home Healthcare Case Study ABB Optical Improves UPH to over […]

Home 3PL Case Study JAS Contract Logistics Select Language English […]