Discover how Staples Canada modernized fulfillment with Locus Robotics, doubling productivity, improving order accuracy by 73%, and cutting training time by 70% through flexible, scalable warehouse automation.

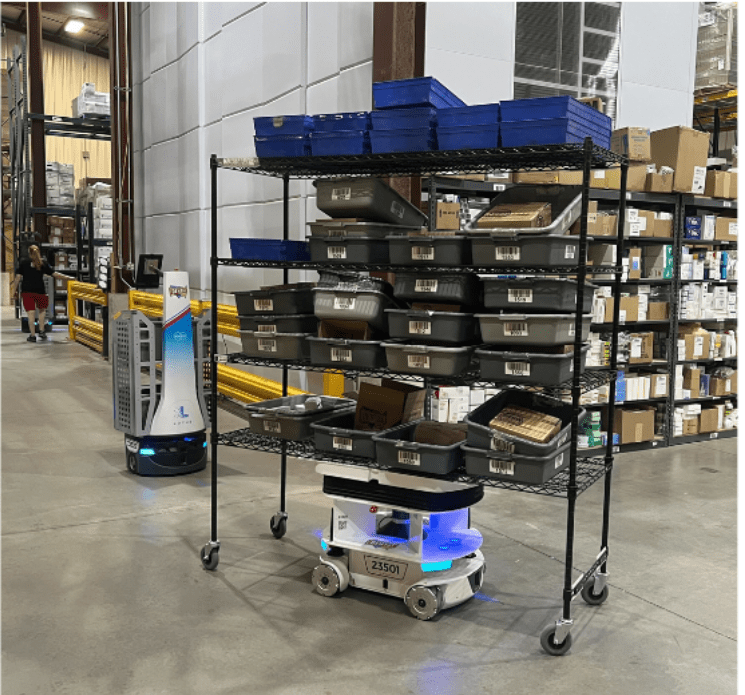

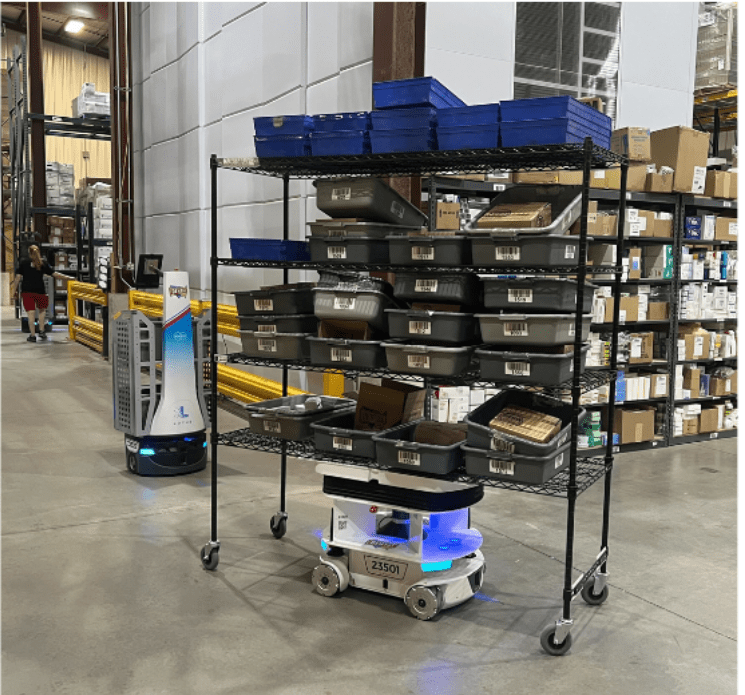

Discover how S&S Activewear increased throughput by 50%, halved training time, and improved employee safety with Locus Robotics’ record-fast 49-day AMR deployment.

Learn how warehouse automation helps you handle peak season with ease to boost throughput, reduce labor strain, and scale operations with AI-driven robotics.

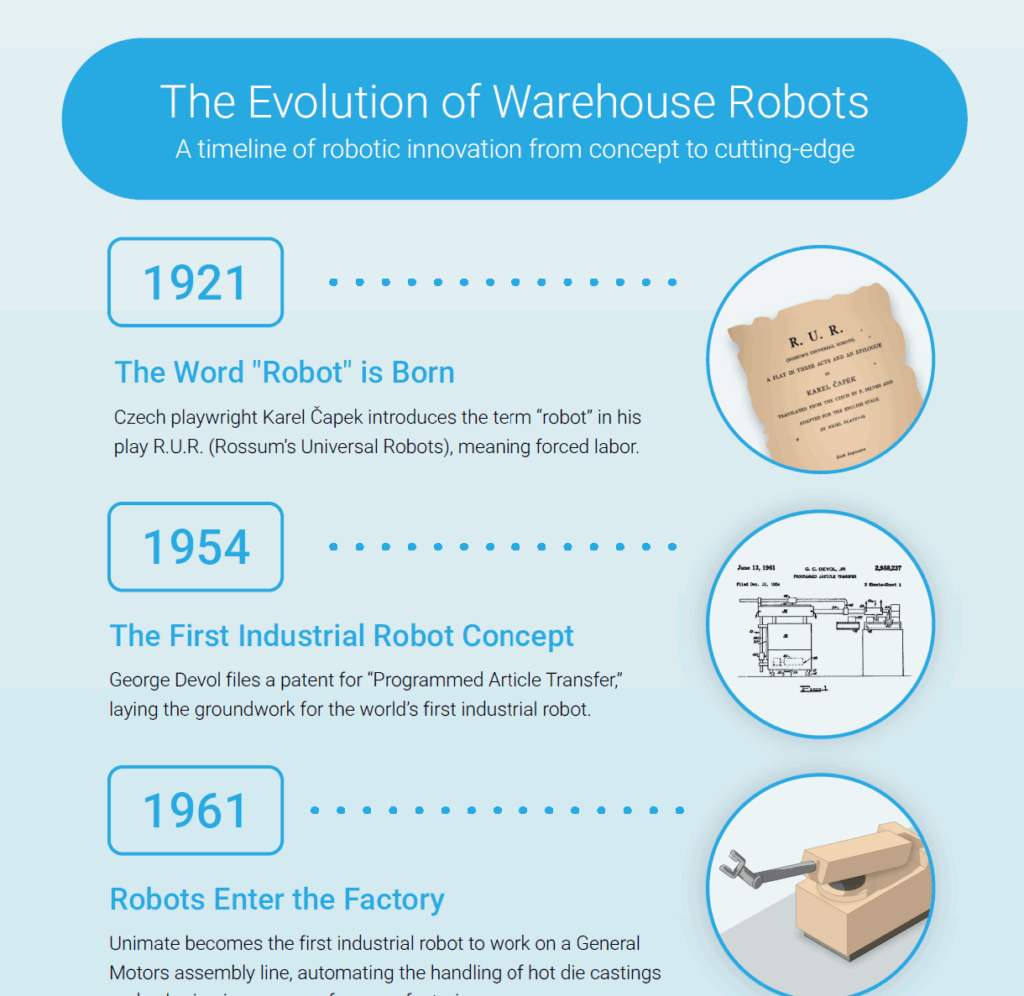

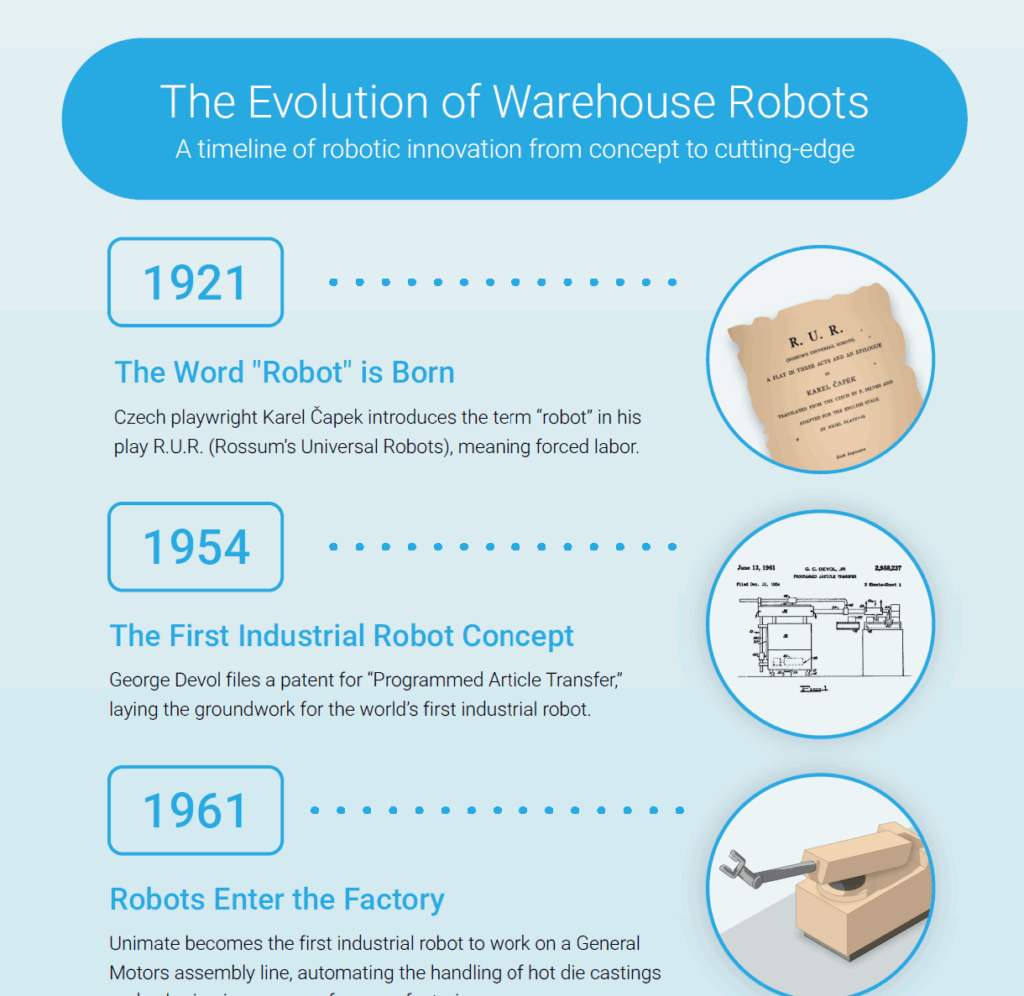

Explore the evolution of warehouse robotics, from early industrial robots to AI-powered fleets, and see how automation drives flexibility, throughput, and efficiency for modern fulfillment operations.

Prepare your warehouse for peak season with this strategic checklist. Identify stress points, assess labor and tech gaps, and plan automation for resilient, scalable operations.

Discover how Motivational Fulfillment boosted productivity by 61% and cut labor needs by 20% using Locus Robotics to deliver faster picks, higher accuracy, and improved associate safety across multiple sites.

Discover how Dental City increased picking productivity by 300% and achieved 99% order accuracy by automating fulfillment with Locus Robotics’ AMRs, without expanding their warehouse footprint.

Explore how AI is transforming warehouses with physical, explainable, and holistic intelligence to boost productivity.

In this episode of Warehouse Automation Matters, Mary Hart interviewed Mert Selcuk, Senior Manager of Supply Chain Strategy and Capabilities at Staples Canada. They discussed the warehouse automation landscape and focused on the implementation challenges, strategies, and technologies involved.

In this episode of Warehouse Automation Matters, Mary Hart interviewed Chris Caouette, Chief Revenue Officer at North Bay Distribution, on challenges and innovations in the 3PL and e-commerce fulfillment space.

Maersk Gains Flexibility and Improves Order Accuracy with Locus Robots

Explore how warehouse robotics delivers faster ROI, reduces operational costs, and boosts fulfillment efficiency. This playbook offers data, case studies, and ROI models to guide smart automation decisions.

In this episode, Mary Hart spoke with Austin Feagins from Staci Americas about the complexities of technology and compliance in beauty product fulfillment. They discuss the unique challenges faced by the beauty industry, including high customer expectations and strict regulations.

Quick and easy integration and deployment, along with Locus’s flexibility helps Boulanger exceed customer expectations.

Discover how agile supply chain strategies and AI-powered warehouse design help operations stay ahead of market shifts. In this webinar, Mary Hart talks with ThruPut Partners’ Kevin Hume.

This white paper explores how Locus Robotics’ Fast Pick functionality helps warehouses achieve up to 400 units per hour by blending the flexibility of Person-to-Goods (P2G) with the speed of Goods-to-Person (G2P) systems. It highlights real-world use cases in e-commerce, healthcare, and retail, showing how Fast Pick boosts throughput, reduces complexity, and adapts to dynamic fulfillment demands.

Discover how Barrett Distribution Centers leverages data-driven decision-making to optimize warehouse operations. Learn key KPIs, slotting strategies, and AI trends in this Warehouse Automation Matters episode with Derek Morse.

In this conversation, Mary Hart interviewed Barbara Porter, COO of Fragrance.com, about top trends in retail warehouse automation. They discussed the significant impact of AI and robotics on operational efficiency, the importance of sustainability, and the challenges faced when integrating new technologies. Porter shared insights on consumer expectations, the balance between speed and quality, and the future role of humans in automated environments. The discussion highlighted the necessity for warehouses to adapt to changing market conditions and the benefits of leveraging automation to enhance productivity and employee satisfaction.

In this episode of Warehouse Automation Matters, host Mary Hart and Kait Peterson, VP of Product Marketing at Locus Robotics, discuss the critical role of flexibility and automation in modern warehouse operations.

By integrating Locus Robots, DHL improved order quality, reduced operational touchpoints, and enabled rapid cycle times, all essential for a healthcare-focused supply chain.

Learn how Fast Pick by Locus Robotics enables unlimited warehouse throughput with P2G flexibility. Streamline bulk and high-demand picking for faster, scalable, and efficient fulfillment tailored to dynamic operational needs.

Discover how modern warehouse automation enhances efficiency beyond picking. From case handling to data-driven insights, explore flexible, scalable solutions for your warehouse operations.

Explore data-driven complex warehouse cartonization, sustainability, and holiday cheer from a licensed Santa Claus.

Stay ahead with the latest warehouse automation trends for eCommerce, from Warehouse Execution Systems to autonomous mobile robots. Check how to optimize inventory and boost efficiency with advanced automation technology.

In this conversation, Mary Hart speaks with Ken Ray about the holidays and warehouse automation through complex cartonization.

Psycho Bunny tripled productivity by partnering with Saddle Creek and leveraging LocusBots to streamline fulfillment across their expanding business.

In this conversation, Mary Hart and Chris Budney discussed the critical aspects of preparing warehouses for peak season. They explored the challenges faced by warehouses, including labor shortages, inventory management, and the importance of technology.

Jennifer Chung, director of automation and innovation for North America with DSV, and Laura Adams, director of customer lifecycle marketing with Locus Robotics, tell how Locus helped DSV to meet the seasonal needs of a key customer.

In this episode of “Warehouse Automation Matters,” Mary Hart sits down with Erik Pichette and Adam Schwarz from Locus Robotics to explore the intricacies of optimizing and automating warehouse mezzanines. They discuss best practices for efficient design, from slotting strategies to handling peak demand, and emphasize the importance of collaboration and planning to avoid common pitfalls. The conversation also highlights how AI, machine learning, and innovative solutions are shaping the future of mezzanine automation to boost productivity and ROI.

This collaboration has provided nGroup with a strategic advantage in the 3PL market, enabling them to deliver exceptional service to their clients while maintaining a safe and efficient workplace.

In this conversation, Mary Hart and Guy Courtin discuss the rise of online pharmacies and their impact on logistics companies. They explore how e-commerce trends are reshaping the pharmacy landscape, the unique challenges of delivering pharmaceuticals, and the role of technology and regulatory requirements in ensuring safe and efficient delivery. The discussion also touches on sustainability, returns, recalls, and the future of logistics in the online pharmacy sector.

Whether you’re grappling with fluctuating order volumes, seeking to reduce labor costs, or aiming to enhance your team’s efficiency, our Vice President of Product Marketing, Kait Peterson will illuminate the path to achieving these goals through the strategic adoption of P2G warehouse automation.

Andy Johnston, Senior Director of Innovation at GEODIS, discussed where to start with warehouse automation and emphasized the importance of identifying the workflow that needs to be solved and then finding the right technology to automate it.

This checklist will help ensure that the robotics solutions being considered prioritize human

safety and can integrate seamlessly into warehouse operations.

Andy Johnston, Senior Director of Innovation at GEODIS, discussed where to start with warehouse automation and emphasized the importance of identifying the workflow that needs to be solved and then finding the right technology to automate it.

P2G automation with AMRs boosts warehouse efficiency by optimizing space, speeding integration, and enhancing safety.

Tim Dolcich of DHL Supply Chain discusses with Mary Hart how robots are automating 3PL fulfillment tasks and the importance of human-robot collaboration for future scalability.

In this webinar, Kait Peterson, Vice President of Product Marketing at Locus Robotics was joined by Casimira “Casey” Federspiel and Song Gao of DHL Supply Chain to discuss the reasons for mezzanines and pick towers in a warehouse, along with why integrating automation into these levels is critical for peak optimization.