Discover how Staples Canada modernized fulfillment with Locus Robotics, doubling productivity, improving order accuracy by 73%, and cutting training time by 70% through flexible, scalable warehouse automation.

Discover how S&S Activewear increased throughput by 50%, halved training time, and improved employee safety with Locus Robotics’ record-fast 49-day AMR deployment.

Discover how Motivational Fulfillment boosted productivity by 61% and cut labor needs by 20% using Locus Robotics to deliver faster picks, higher accuracy, and improved associate safety across multiple sites.

Discover how Dental City increased picking productivity by 300% and achieved 99% order accuracy by automating fulfillment with Locus Robotics’ AMRs, without expanding their warehouse footprint.

Maersk Gains Flexibility and Improves Order Accuracy with Locus Robots

Quick and easy integration and deployment, along with Locus’s flexibility helps Boulanger exceed customer expectations.

By integrating Locus Robots, DHL improved order quality, reduced operational touchpoints, and enabled rapid cycle times, all essential for a healthcare-focused supply chain.

Psycho Bunny tripled productivity by partnering with Saddle Creek and leveraging LocusBots to streamline fulfillment across their expanding business.

This collaboration has provided nGroup with a strategic advantage in the 3PL market, enabling them to deliver exceptional service to their clients while maintaining a safe and efficient workplace.

Fleet Feet partnered with Körber and Locus Robotics to implement autonomous mobile robots, boosting warehouse efficiency, speeding up training, and doubling order fulfillment.

More than 80% of warehouses aren’t automated because they’re still using old, ineffective manual processes. Use this checklist to determine if your warehouse could be more efficient with automation.

Go! Retail uses Locus Robts for both picking and putaway, after learning that the robots were dual-purpose.

Locus Robotics has spurred DHL Supply Chain to improve other areas of their building, from the conveyor line to improved packaging operations.

Locus Robotics worked with MyPillow to implement 33 AMRs at the Shakopee, MN facility near the end of 2022. The team quickly saw results in their operations and continued to feel confident about their decision.

Home Case Study Warehouse Efficiency Soars at Premier® Yarns with […]

See how Concordance Healthcare Solutions transformed distribution with Locus Robotics, boosting efficiency and employee retention.

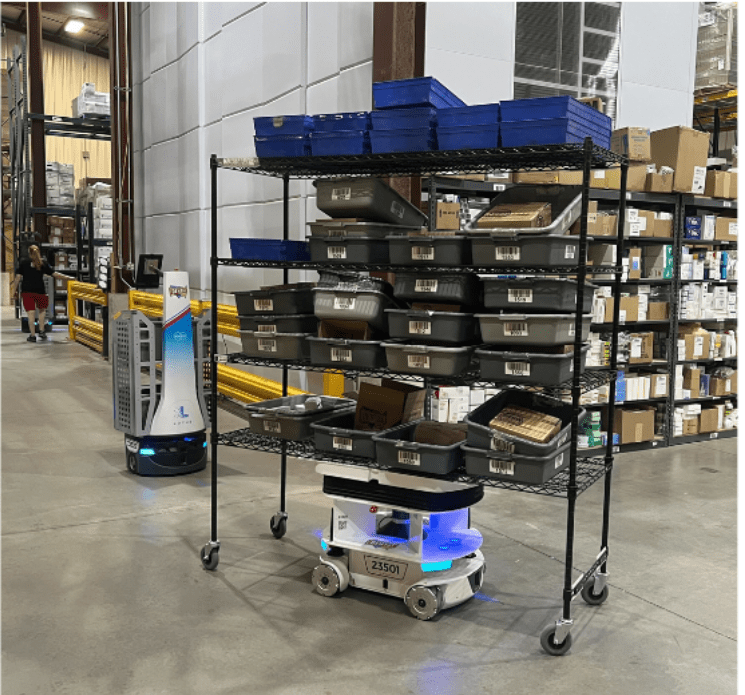

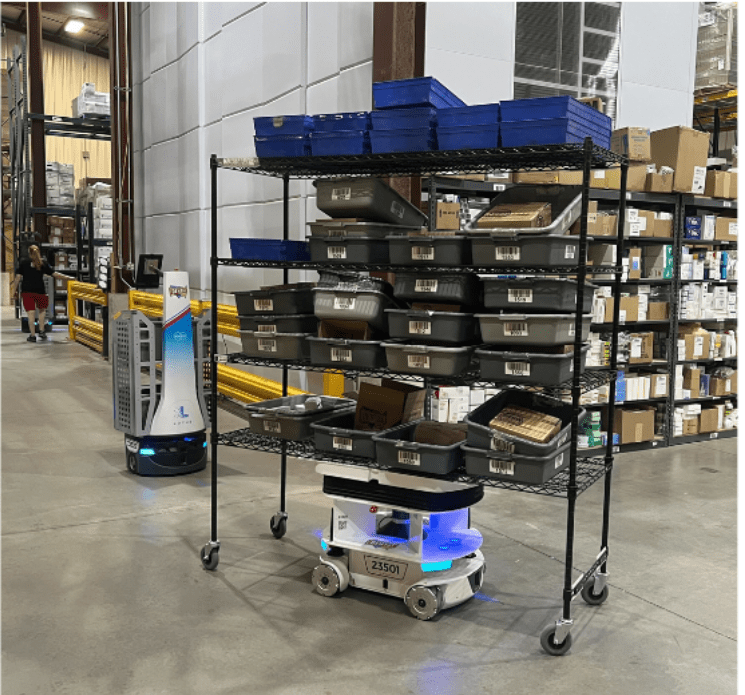

The GEODIS team decided to use autonomous mobile robots (AMRs) to optimize logistics operations in the warehouse and chose Locus Robotics as their vendor. GEODIS integrated 12 Locus Vector with Cart AMRs across a 40,000 square feet picking area. The Vector AMRs are unique — they can attach and handle carts, allowing for the transportation of heavier products and increasing the throughput of orders per mission.”

Home 3PL Case Study Bluegrass Supply Chain View The Case […]

Home Healthcare Case Study UPS Healthcare improves picking time with […]

Home 3PL Case Study Amware Download the Case Study “Having […]

Home Case Study: UniPharma Retailer Unipharma Expedites Their Healthcare Orders […]

Home 3PL Case Study JAS Contract Logistics Select Language English […]

Home 3PL Case Study FM Logistic Select Language English German […]

Home 3PL Case Study Global Freight Management Download the Case […]

Home Industrial Case Study Brother Improves Warehouse Efficiency with Locus […]

Home Case Study: Cardinal Health Cardinal Health Doubles Warehouse Effectiveness […]

Home Retail Case Study Carhartt Shares How They Leverage DHL/Locus […]

Home Case Study: UPS UPS doubles productivity with Locus Robotics […]

Case study on how Kenco addresses labor shortages and increased demand with the help of the Locus solution, significantly improving productivity.

Home Case Study: DSV DSV Providing Same Day Customer and […]

Home 3PL Case Study Geodis Improves Productivity by 2x with […]

Home Case Study: Radial Locus Improves Productivity in Multi-level Pick […]

Home Case Study: Verst Logistics VERST fulfillment productivity soars more […]

Home Case Study: GEODIS LocusBots Ease Labor, Safety Challenges for […]

Home Automotive Case Study ISN Doubles Productivity of Automotive Supply […]

Home 3PL Case Study Saddle Creek Logistics Services Leveraging Locus […]

Home 3PL Case Study GEODIS Drives Digital Transformation with Locus […]

Home Case Study: Port Logistics Group Port Logistics Group – […]

Home Case Study: Boots UK Boots UK – High volume […]