WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

The Most Popular Ways to Use Robotics in Your Warehouse

Mary Hart, Sr. Content Marketing Manager

According to a Peerless Research Group survey, over 40% of warehouses have yet to install a robotics automation system or service. If you’re part of that group, you might be wondering what robotics could do for your fulfillment center. Let’s look at how facilities like yours have benefited from robotics. It might just change your mind.

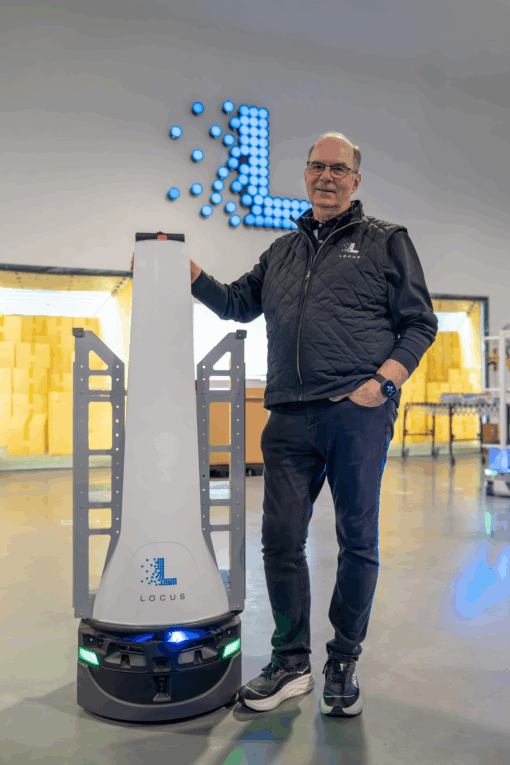

Meet Your Robot Coworkers

BMW found that robots and humans working together are 85% more productive than humans working alone. As an added benefit, warehouse and fulfillment center associates love working with LocusBots.

“It’s very simple,” said Elio Rodriguez, Warehouse Picker at Geodis. “I like working better with the robot because it’s faster and it’s easier.”

Tanya Snyder, Customer Service representative at Geodis, concurs, saying “I was ecstatic when I first saw the robots. When they brought them over to returns, I wanted to be the first one to learn.”

Facilities also rave about the ability to get associates up and working quickly with the LocusBots. Compared to training associates on traditional cart- picking methods including handheld scanners, gauntlets, and other additional tools, training new hires to collaborate with LocusBots has drastically reduced the time it takes to get new associates picking, and then their productivity increases with the bots.

Increased Picking Productivity

At Geodis, “Some of the benefits we’ve seen with Locus are picking productivity and efficiency, “ said Eli Camplei, Director of Operations. Warehouse associates who were averaging 100 UPH with traditional picking methods are now averaging upwards of 175 UPH, and even around 200 UPH, with the Locus solution.

Picking productivity has also improved at Kenco after they implemented the Locus Solution. “Prior to the LocusBots, we were at 30-40 units per hour per picker,” said Kristi Montgomery, VP of Innovation, Research and Development. “We’re now in the range of anywhere from 120-150 units per hour. We’ve also increased our volume and throughput and increased our visibility to what’s happening on the floor.”

Real-Time Insights

With Locus, facilities like Kenco above and Carhartt have gained immediate, actionable data from the software. "With the dashboard, we can see when products are starting to ramp up and go out by tracking where the robots are going on a day-to-day basis," said Tony Gariety, VP of Distribution Operations. “We make adjustments based on that data to place more products into the needed areas to reduce traffic.” The live mapping gives Carhartt the information they need to improve efficiency throughout the year, and even during peak.

Meet Peak Volume Increases

Thanks to Locus, peak season was incredibly successful for DHL. Justin Kastman, Director of Operations, said "We had a record day of over 110,000 units picked that were supported by Locus in the each pick process."

Reduce Costs

Our customers praise the cost reductions they gain by moving to robotics. Locus Robotics’ Robots-as-a-Service purchasing model allowed Kenco’s customer to avoid a large capital expense by reallocating the cost into the operating budget with the ability to increase and decrease with order volumes.

The costs can also be found in training time. Instead of spending weeks training a new associate, they can be trained in less than a day on the Locus solution and get to working on the floor. “It’s a huge cost savings factor when you’re constantly bringing new people during peak season,” said Felix Torres, Assistant Operations Manager at Geodis. With Locus, new associates can get up to speed quickly and work faster.

Now that you’ve seen how these facilities have benefited from robotics automation, are you curious as to how you can gain the same benefits in your facility?

Talk to us and we’ll tell you more!