WP: How to achieve 400 UPH with Locus Fast Pick

We’ve seen UPH productivity double, which is huge to anybody operating warehouses on a costs and efficiency play.

Carhartt

Overview & Challenge

Established in 1889, Carhartt is a global premium workwear brand with a rich heritage of developing rugged products for workers on and off the job. To accelerate their growth, Carhartt needed a way they could quickly scale and close their capacity gap to improve distribution and speed.

DHL Supply Chain, a world-leader in thirdparty fulfillment and logistics, was an ideal choice.

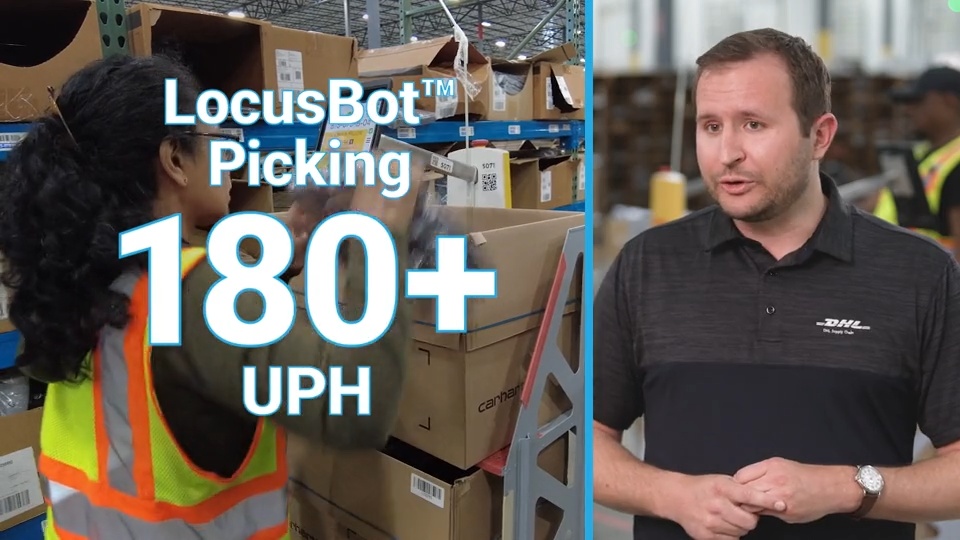

After reviewing options, DHL recommended the Locus solution to help optimize order profiles and “lessen the amount of walking associates had to do. To minimize that, we chose LocusBots to close the gap of some of the physicality and the space challenges of big volume warehousing.” said Tony Gariety, Vice President of Distribution Operations at Carhartt.

With the Locus deployment, “we saw immediate impact to productivity and throughput on day one as well as a big boost in employee morale," said Tim Dolcich, Director of Engineering, DHL.”