Webinar Registration: The P2G Advantage

Overview & Challenge

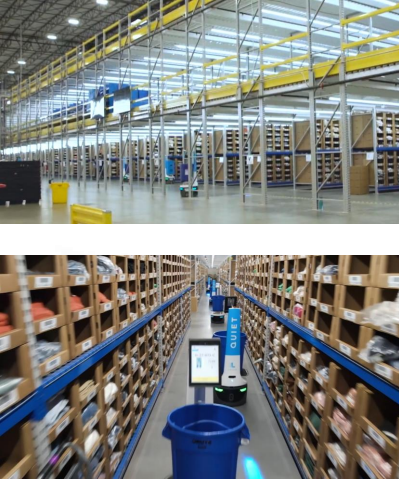

Quiet Logistics is one of the largest third-party fulfillment companies utilizing mobile robot automation. It specializes in inventory management, delivery, and personalized brand experiences for ecommerce retailers. For 6 years, Locus AMRs have helped Quiet with one of its most important customer demands: fast deliveries shipped same-day.

Like many operations seeking to get more out of the same square footage, Quiet warehouses have built vertical fulfillment levels using mezzanines. Each mezzanine is about 74,000 ft2 and adds a layer of complexity when it comes to fulfilling orders quickly with items that are located on different levels.

“The biggest differentiator with Locus is our multi-bot approach. That’s how we can really provide meaningful productivity improvements,” said Steve Branch, Sr. Director of Sales Engineering at Locus Robotics. The Locus fleet recently grew with the acquisition of cutting-edge heavy duty robots, adding the ability to support a full spectrum of product sizes and weights from each picks to heavy pallets.

Locus’s robotics-enabled warehouse execution platform uses the multi-bot approach to optimize.