WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Material Handling Robotics Don't Change and Improve Over Time - Until Now!

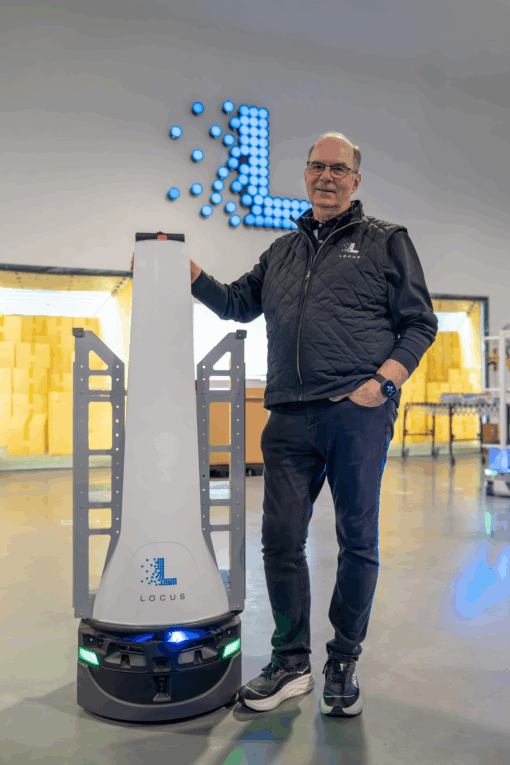

Mike Johnson, President & Chief Operating Officer

LocusEmpower, a robotic, task-based execution system, has the fantastic ability to extend and improve its capabilities with no operator intervention.

It goes without saying that at Locus Robotics, we love technology. Especially robots. You need not look any further than our in-house robot museum and the many spaces filled with robots, images of robots, along with the many LEGO and Star Wars robots to know that our whole company lives and dreams in robots.

So, why do we love robots so much?

The physical Robot is cool, but the magic comes from the virtual side. The innovation is in the software.

Locus has a deep-rooted heritage in the material handling and warehousing industry. We have supported the design and implementation of hundreds of different material handling solutions. In today's new high-tech world, we envision flexibility, change, and continuous improvement. So the ability to design and build a significant material handling solution (the physical robot) and have it improve (evolve) over time is our dream come true.

So how does this happen?

The dream comes to life through a wonderful (and amazing) balance of robot hardware and software! The fantastic thing is that Locus is not only advancing the use-cases that a robot can perform, but also increasing the performance of each function. Imagine if you had a traditional conveyor system that, all of a sudden, could do something different or could instantly process more material. In reality this is not possible, so the use case and capacity of your material handling systems is fixed and limited.

Today, our LocusBots consistently improve associates’ picking performance by a factor of 2X-3X, and that figure will continue to grow significantly over time. Overnight, the available use cases can be extended, and the overall capacity and performance of the system can grow as your operation and business grows or changes.

Here are some incredible incremental improvements we have deployed over time (the same robot in a facility gets better!):

- Better navigation - the robot is smarter and is able to get to the location faster while easily navigating and managing any significant changes to the facility

- New apps - we've added new features such as put-away, transport (point-to-point deliveries), new types of picking

- Gamification/incentives for the associates

- Workflow direction - we optimize worker productivity by directing them to the nearest pick, saving unproductive walking time and item locating

- Robots dreaming of new ways to help you - OK, we actually do not have this. But we humans are always thinking of new use cases and are working hard to develop them! We would love to hear the particular use cases you have!

Your business demands flexibility and the ability to deal with change. At Locus, we do the work to make this easy for you. Your investment in Locus will keep evolving and growing as you do. New performance improvements, new use cases, and other new features are automatically pushed the Locus Robotics solution giving you the latest and highest performing material handling equipment in the industry.

Imagine if, every day, your material handling solution could get better and better. Well, imagine no more…..it CAN!

About the Author

Mike’s 30 years of technical and business leadership experience inform everything from the design of our robots to tackling the practical challenges of a rapidly scaling organization. Nimbly navigating EBITDA, ROI, UPH, CPU, UPO, SLA, FIFO, XML, SQL, C++, and AWS, to name a few, Mike is a logistics industry veteran and expert who intrinsically understands the operational challenges of our customers. He has been instrumental in establishing Locus Robotics as a leader in the Logistics and AMR space, exemplifying our focus on technology in service to the real-world needs of warehouse operators around the globe.