WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Late to the Automation Game? Find the Right Solution

Mary Hart, Sr. Content Marketing Manager

According to research from Gartner that was revealed at the Gartner Supply Chain Symposium, employee turnover in the supply chain is 33% more than it was pre-pandemic. Warehouses are struggling to keep the associates they have and hire new full-time or temporary associates to fill those positions.

Labor challenges and what warehouses can do about them were the subject of a recent Supply Chain Brain webinar, “Say Goodbye to Supply Chain Woes With Berkshire Grey and Locus Robotics' Best-in-Class Integrated Solution”.

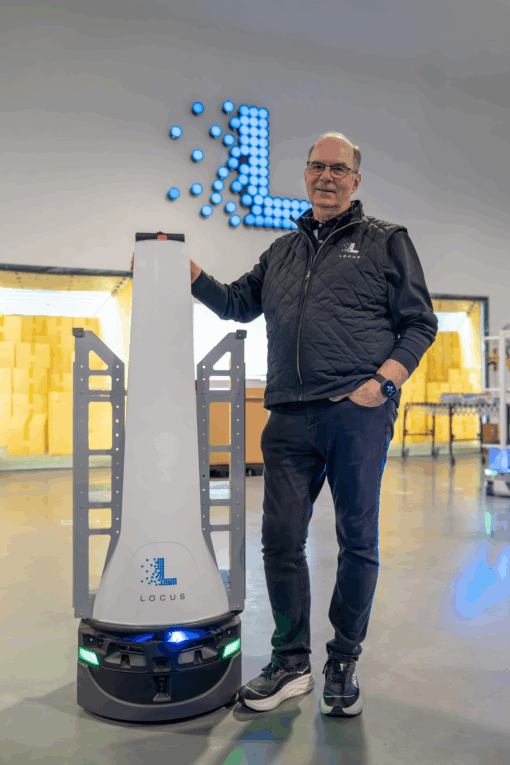

In this webinar, Steve Branch, Vice President of Sales Engineering at Locus Robotics sat down with Noah Maynard, Principal Solutions Architect at Berkshire Grey to discuss the key business issues facing warehouses today and how their new integrated solution can help.

Key Business Struggles for Warehouses

Today’s warehouse executives have to deal with a number of stumbling blocks to succeed, which can include:

- Labor scarcity

- Costs of labor to meet living wages and be competitive

- Growing demands from customers or clients

- Insufficient capacity to handle the next peak with space and labor constraints

- A market that’s flooded with point solutions

Customers are demanding flexible and seamlessly integrated best of breed robotic automation solutions to address these challenges and deliver top-quality customer experiences.

That solution can be found in the new combined solution from Berkshire Grey and Locus Robotics.

Put Wall + Bots = Success

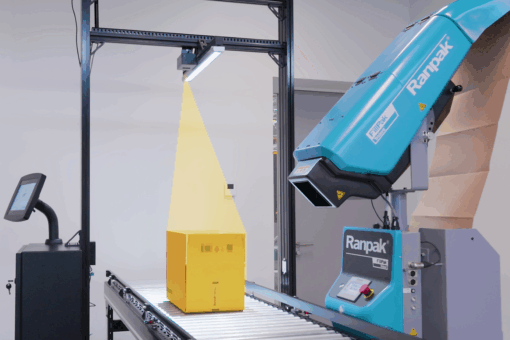

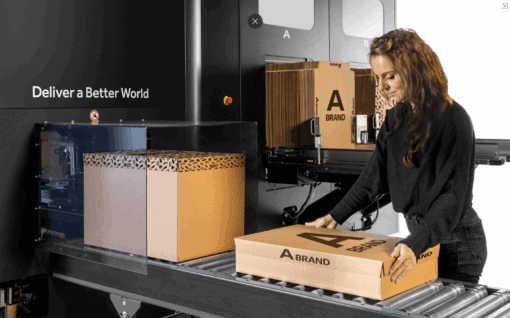

Berkshire Grey and Locus Robotics combined solution brings together the Berkshire Grey Robotic Shuttle Put Wall with Identification (BG RSPWi), which can hold up to 240 orders, with the Locus Origin and Locus Vector autonomous mobile robots (AMRs).

The solution uses the Put Wall, AMRs, and human associates together for automated picking and putaway. On the webinar, Maynard noted that thanks to the AMRs, the Put Wall can be implemented quickly and flexibly in a warehouse as conveyors aren’t needed.

Customers also benefit from the tight partnership that led to this integration, along with the flexibility and scalability to adapt to a warehouse’s changing needs over time.

Improve Associate Productivity

With the joint solution from Berkshire Grey and Locus Robotics, warehouses can get more capacity out of their facility with the same amount of labor.

“Warehouses that have implemented the combined solution have seen their batch picking productivity improve by 50% or more without changing the number of associates,” said Branch. For sortation, rates that were in the 250 to 275 range increased to the 750 to 800 range by adding the solution.

This solution also provides these benefits with your current warehouse associates:

- Sort customer orders 3x faster

- Streamline the takeaway and pack-out processes

- Increased productivity with near 100% SKU coverage

- Improve picking productivity by 1.5-2x

- Reduce space required for consolidation by 70-80%

- Minimal fixed infrastructure

Why Automation is the Present and Future

Warehouses that aren’t augmenting their workers with automation are behind the curve, according to Maynard who shared his thoughts on why customers should move to warehouse automation.

“Those who haven’t automated are late to the game,” said Maynard. “There is a lot of opportunity out there for automation. When you automate, you’ll get the benefits of the efficiencies quickly.”

With the combined solution, customers also have the ability to add more put walls over time; add pick paths; and add bots as order needs change and your warehouse expands and grows.

Unlike conventional fixed solutions, the Berkshire Grey and Locus Robotics’ solution can be added to and updated without any interruption to your warehouse operations.

Is This Solution Right for Your Warehouse?

When asked for a profile of the best type of facility for this solution, Branch offered the following:

- eCommerce, Retail, or Wholesale

- 800 units per hour (UPH) of throughput or more. Any less may not yet need this solution.

- Large pick floors where SKUs are spread throughout the facility

- Multi-zones and multi-level mezzanines

He also suggested a few things to consider before looking for a new solution:

- Know your requirements and order profile

- Assess the dimensions and weight of the products you pick and put away

Maynard added that warehouses should get a picture of their operations and costs as they are today. Look for solutions that will grow with your facility over time and not interrupt your current operations.

If you’re wondering if your facility is a fit for the Berkshire Grey and Locus Robotics’ combined solution, engage with a provider and consider a site visit.

Talk to us and we’ll tell you more!