WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Locus Robotics and Sustainability in the Circular Economy

Mary Hart, Sr. Content Marketing Manager

The concept of the “Circular Economy” was developed by Ellen MacArthur to address climate change, biodiversity loss, waste, and pollution by separating economic activity from the consumption of finite resources. Underpinned by a transition to renewable energy and materials, the circular economy is a system benefiting business, people, and the environment.

There are three main principles of the circular economy:

- Eliminate waste and pollution

- Circulate products and materials

- Regenerate nature

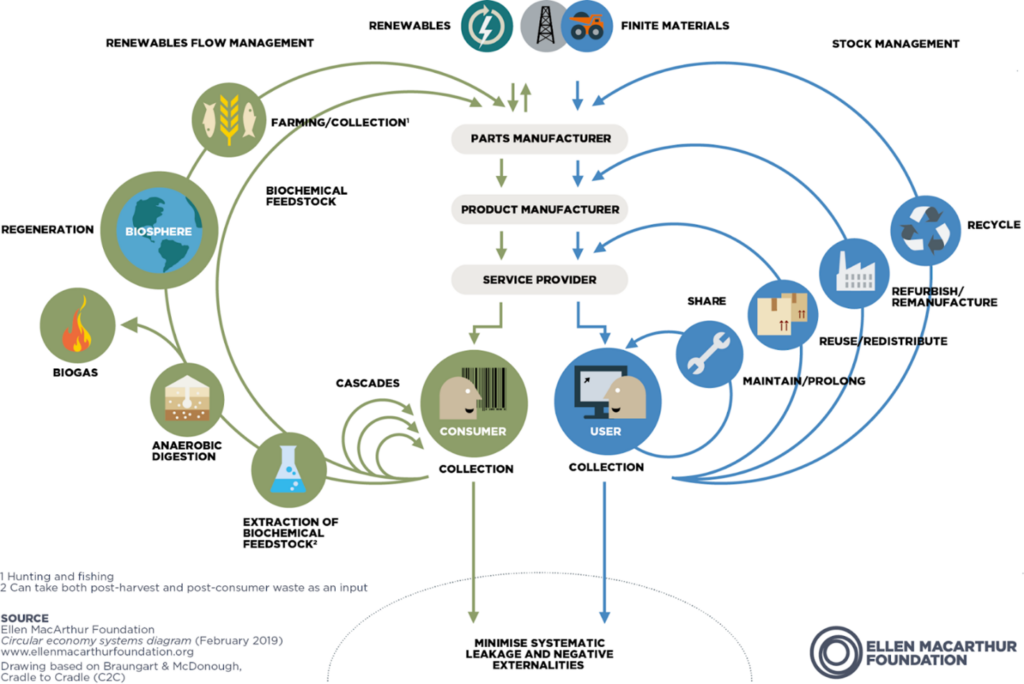

The diagram below illustrates the continuous flow of materials in a circular economy. There are two main cycles: the technical cycle (right) and the biological cycle (left). In the technical cycle, products and materials are kept in circulation for as long as possible while in the biological cycle, nutrients from biodegradable materials are returned to the earth to regenerate.

The focus of this blog is on the technological cycle, which covers items that are not biodegradable such as metals and plastics. In this cycle, products and materials maintain their highest possible value, while opportunities to generate value come through retaining the greatest proportion of labor and energy embedded in products.

The technical cycle of the circular economy functions through circles of activity between users; service providers; product manufacturers; and parts manufacturers. Each practice aims to maintain the highest value of a product by extending its period of use.

Circle 1: Share

The first circle in the technical cycle is sharing. In a circular economy, the practice of sharing is the use of a product by multiple users. For example, arranging a carpool so that a car can be shared by several people is less resource intensive than building more cars.

Circle 2: Maintain / Prolong

The second circle in the technical cycle is maintaining/prolonging. In a circular economy, the practice of maintaining or prolonging, keeps a product in its existing state of quality, functionality, and/or cosmetically to guard against failure or decline. In this case, the service provider keeps the product running smoothly through regular maintenance and repairs.

Circle 3: Reuse / Redistribute

The third circle in the technical cycle is reusing/ redistributing. In a circular economy, the practice of redistributing diverts a product from one market to another customer, so it is used at high value instead of becoming waste. For example, a supermarket can redistribute surplus edible food to a foodbank.

Circle 4: Refurbish / Remanufacture

The fourth circle in the technical cycle is refurbishing and remanufacturing. In a circular economy, the practice of refurbishing returns a product to good working order. This can include repairing or replacing components, updating specifications, and improving cosmetic appearance. For example, a car manufacturer can remanufacture the engine of a car along with other components when they are no longer useable.

Circle 5: Recycle

The fifth circle in the technical cycle is recycling. In a circular economy, the practice of recycling transforms a product or component into its basic materials or substances and processes them into new materials. Embedded energy and value are lost in the recycling process, therefore in a circular economy recycling is the last resort action.

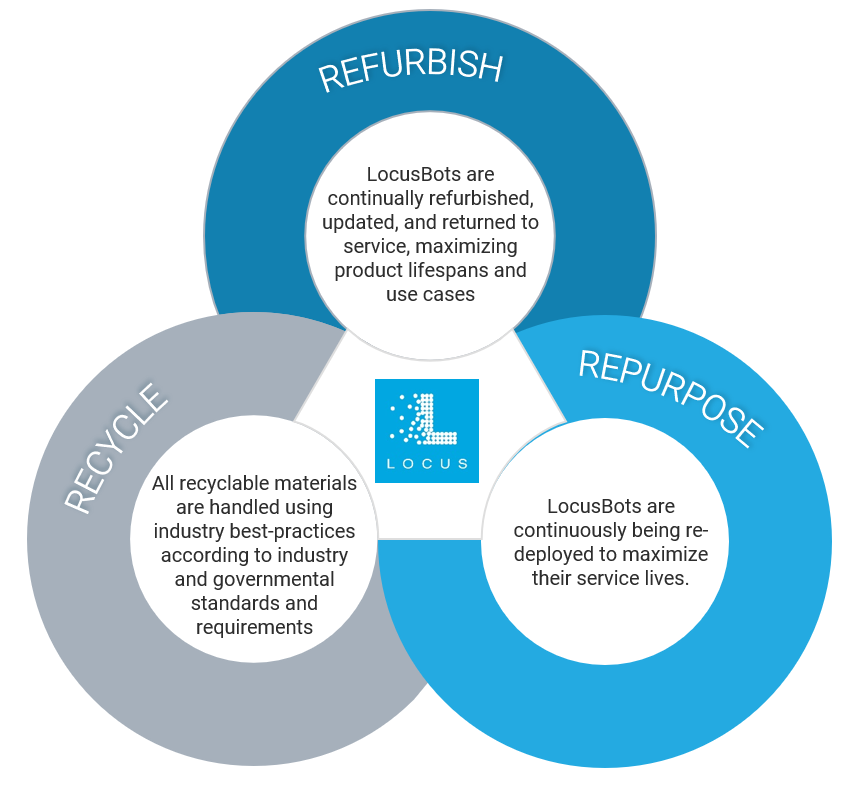

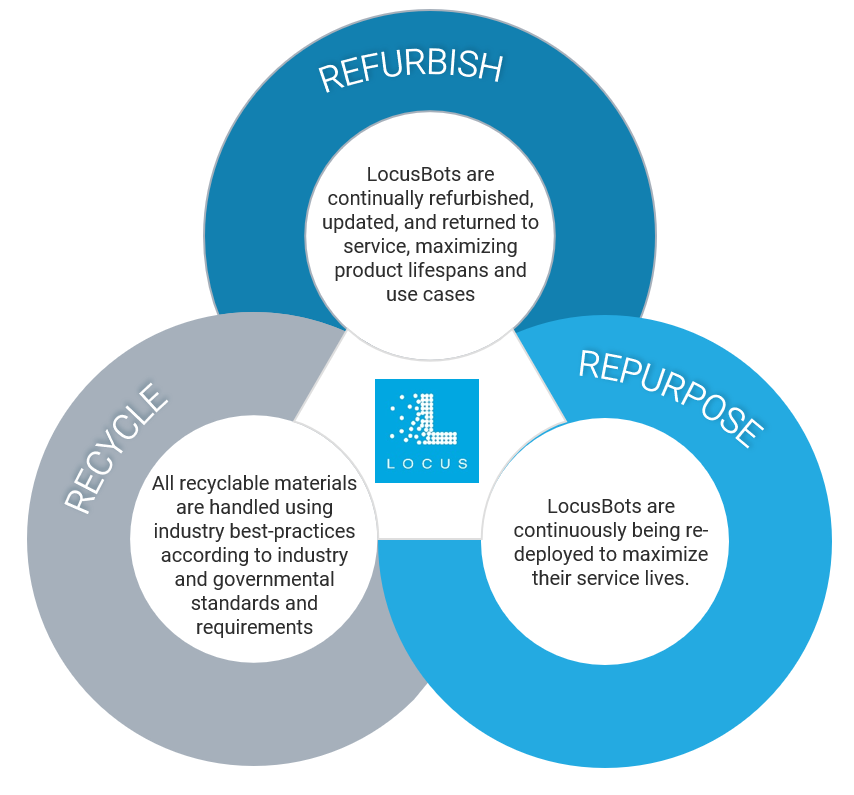

As we review the “3 Rs” of our Locus Robotics’ sustainability initiative: Refurbish, Repurpose, Recycle, you will see how each “R” is a fundamental aspect of four of the five circular economy technical cycles described above.

- Repurpose: The practice of repurposing is where our robots-as-a-service (RaaS) model comes into play as an interaction between Locus, the product manufacturer and our customers, the user. Since customers do not own the LocusBots, we sustainably maintain the robots in the field. Through this subscription model, customers receive a fleet of Locus’s autonomous mobile robots (AMRs). Customers can increase or decrease their number of LocusBots are their needs change. This often occurs during a warehouse’s peak season when facilities recruit more bots to manage the increase in order volume. Customers can either convert those LocusBots to permanent use in their warehouse or the bots can be sent back to Locus for refurbishment. Once a LocusBot is refurbished, Locus repurposes the LocusBot to other customers. No robots go to waste.

- Locus Robotics Field Service Team preventive maintenance (PM) prolongs the life of the bot while operating and also repairs/refurbishes product in the field with no disruption to Customers.

- Refurbish: LocusBots are continually updated and returned to service, therefore ensuring their highest value, and maximizing product lifespans. The typical lifespan for a LocusBot would typically be five to seven years given the evolution of technology. However, Locus’s refurbishing processes extend the life of a LocusBot well beyond this time period.

- Recycle: The major components in LocusBots include ABS plastic, metal casings, batteries, printed circuit boards, and related electronics. Because the useful life of each component varies, recycling is only done when a component or part is unable to be refurbished or repurposed.

Here at Locus Robotics, we actively drive sustainability across all aspects of our business. We comply with globally recognized social and environmental standards, and our primary goals is to create and deliver high quality, innovative warehouse automation that remains highly efficiency through its service life to identifying and implementing best-practice strategies and tactics to reduce overall waste across all areas of our organization.

Contact us to find out more!