WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Smart Manufacturing in 2020: the year of product changeovers

Jeff Cody, Director of Interactive Marketing

By David Paquin | Director of Industrial, Locus Robotics

2020 has been the year of product changeovers in supply chain. Most manufacturers that had plans to digitize in the future were hard-hit with manual changes.

- Manually moving previous product to make room for new demand

- Manually changing processes to accommodate new manufacturing

- Manually stocking new product and fulfilling orders while social-distancing

- Manually monitoring demand and changes to be ready for the next shift

- Hiring extra labor to help with the manual changes

For the early adopters of digital supply chain transformation and smart manufacturing, the changes in demand have been manageable and quick to adapt to.

- Robots move products through the warehouse, allowing workers to focus

- Robots are integrated with WMS and other systems, inheriting information and requiring no changes

- Robots enforce social distancing by design, requiring no changes

- Robots seamlessly switch between pick and putaway tasks, requiring no changes

- Robotic solutions include real-time dashboards and reporting tools that monitor the changes in demand for you, allowing you to make decisions using the most current analyses

- Robots operate as an extension of each worker, driving more productivity using the same footprint of people and space

Unfounded concerns

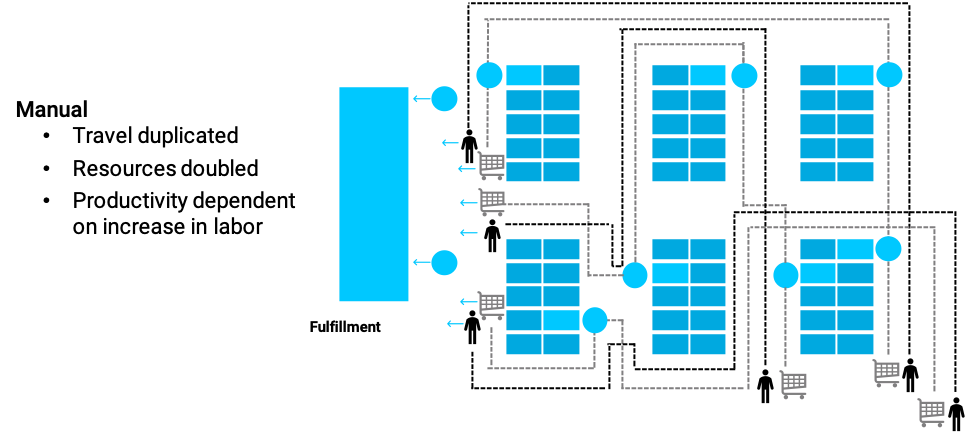

Manufacturers are not looking for temporary fixes to simply meet peak or overcome pandemic-caused conditions; the adoption of robotic technology and smart manufacturing is making permanent waves across the supply chain. Investments and research have been paving the way to a robotic future, and the pandemic is just the latest catalyst for digital transformation, according to Gartner. An increasingly global, increasingly virtual world is driving new demand at faster rates and manufacturers are looking for ways to get the right product to the right customers faster.

There is a concern among manufacturers that new technology requires a fresh greenfield re-model and they wait for the right opportunity to take the advantage. While greenfield developments are optimal for new technology, the brownfield approach is more suitable for most and technology providers are working with facilities to optimize their current operations. Manufacturers benefit the most from bringing providers to the table earlier in their plans because providers use highly accurate simulations to create the business case.

Gartner researchers encourage manufacturers to seek out new innovations that promise long-term success, and not to rely on short term results (i.e. expecting measurable returns in year one). They also stress the importance of balancing innovation with exploitation of the technology once it’s been proven to increase productivity. In the case of greenfield builds, a technology solution is implemented and then exploited to scale and lead to additional areas of opportunity for automation. Brownfield implementations are often exciting for the facility, management, and workers because the manufacturer (often through the automation provider) measures current metrics and productivity levels, which are used to compare the success of the new technology and provides a great business case for the expansion or duplication of it.

Robotic automation solutions for material handling and movement

Augmenting manufacturing environments with a robotic solution requires months of internal planning that can be reduced by bringing automation providers to the table early on. Providers have their engineers and experienced productivity designers evaluate operations (often with highly proficient simulations) and are extremely committed to the success of the solution.

Large decision factors will narrow down the list of potential robotic solutions including cost, size, infrastructure requirements, and operational downtime during installation. For example, robots that run on a grid require massive infrastructure planning and changes, and in most cases cannot be installed in the same space that current operations are running.

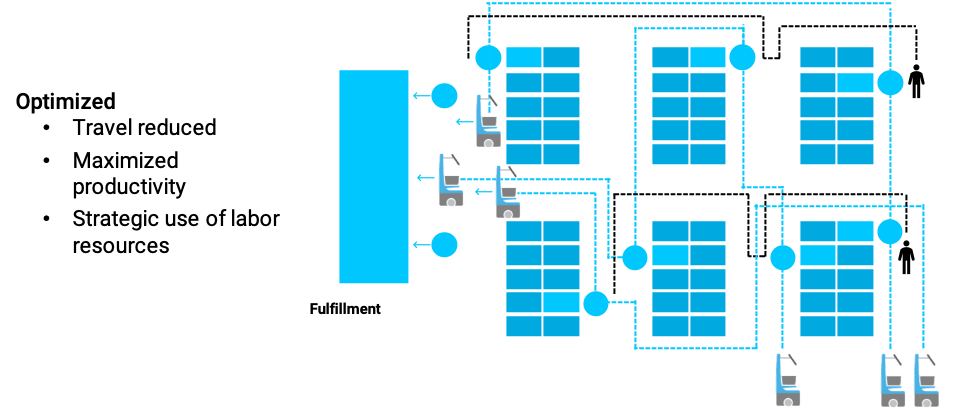

Robotic arms can move items effectively but cannot be the only solution implemented; they require a hybrid automation solution, working in tandem with conveyor belts and other robots or machines to fulfill orders, which is very costly. For these reasons, many manufacturers are turning to a multi-bot solution that requires little infrastructure changes, can be installed in working operations, and multiplies the productivity of workers while returning an ROI within months instead of years.

The multi-bot solution

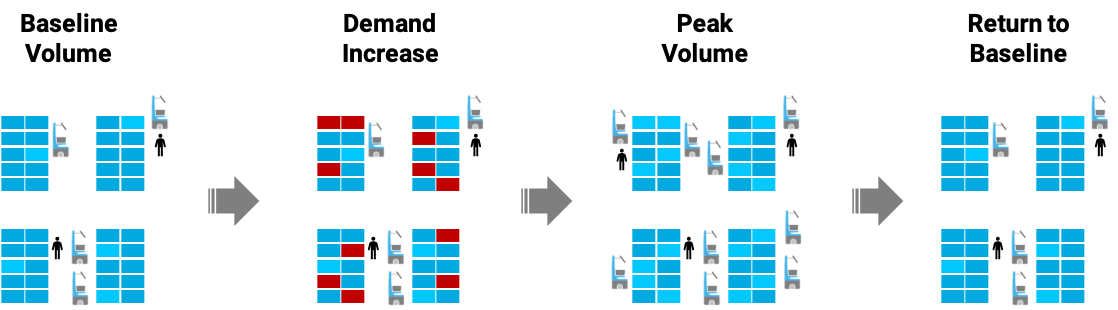

The multi-bot solution uses autonomous mobile robots (AMR) and runs on a Robots-as-a-Service (RaaS) model, essentially removing the up-front capital costs that cripple many plans to automate. Manufacturers monitor their demand in real-time and place an order for additional robots when volume increases, then send them back to return to the baseline operation. The fleet of robots is also safe enough to operate in dense environments, fulfilling orders of various sizes/materials, or traveling narrow aisles to many locations.

A multi-bot solution is so flexible, it is capable of high performance in hybrid human-centric environments with full social-distancing cooperation as well as dark fulfillment centers. Being highly portable, it does not limit facilities to keep unbusy robots in a particular site as robots can be moved between multiple sites based on demand. This power of flexibility strengthens operations to weather through the most unexpected demand increases or changes; it future-proofs the entire operation.

Small and large manufacturers reap the benefits of a multi-bot solution to solve some of the most difficult problems including order accuracy, training, contract turnover, and limits in capital expenditure. Workers express positivity and excitement about their robot coworkers and experience improved personal job performance as their order accuracy reaches near-perfect rates. In current pandemic conditions, a multi-bot solution provides social distancing measures as part of its design, maintaining an operation’s high productivity while complying with CDC guidelines.

Watch what executives and managers are saying about the Locus multi-bot solution in their operations. IT integration teams from various companies also offer their perspectives on deploying a multi-bot solution.