WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

The Ever-Peak Playbook: How 3PLs Can Scale Smarter Year-Round

Mary Hart, Sr. Content Marketing Manager

In fulfillment, the idea of “peak season” used to mean long hours, extra staff, and the annual sprint toward holiday deadlines, but that rhythm has disappeared. Order volumes no longer spike once a year. Instead, they surge constantly, driven by influencer promotions, flash sales, and consumer expectations for immediate delivery.

On an episode of the “Warehouse Automation Matters” podcast, Adam Lawicki, VP of Strategy at scale3PL, described this new reality as Ever-Peak, which is the state of always-on demand that defines modern logistics. “July now looks like November,” he said. “If you’re not automating, you’re going to be left behind.”

Ever-Peak fulfillment requires a new mindset that is built around adaptability, precision, and systems that scale in real time. Here’s how scale3PL redesigned its operation to thrive under continuous pressure and what every 3PL can learn from its approach by using automation partners like Locus Robotics to enable this model.

Automate the Standard Work

The biggest threat to growth isn’t rising demand but falling behind it. scale3PL knew that manual processes, however effective in smaller bursts, would eventually create friction as volume compounded.

“We wanted to automate what we’d call the standard work — the table stakes,” Lawicki said. “That means every order ships on time, at the lowest possible cost, while our people focus on the exceptions.”

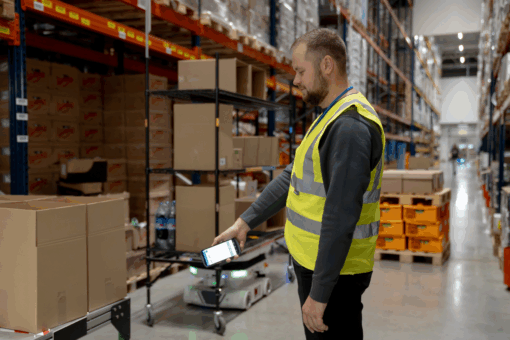

To meet that goal, scale3PL automated the baseline tasks that underpin fulfillment in picking, packing, and scanning. Those activities now run on reliable, repeatable systems that minimize delay and error. As a result, associates can dedicate their energy to improving processes rather than catching up on them.

Your Move:

- Map out every recurring task in your fulfillment flow — the ones that must happen perfectly every time.

- Apply automation where predictability exists and use human oversight where context matters.

- Reinvest efficiency gains into continuous improvement initiatives.

Redefine the Role of People

Automation and people aren’t competing forces; they’re complementary. At scale3PL, introducing technology was about freeing employees from repetitive strain so they could focus on judgment-based work.

“The automation handles what should happen automatically,” Lawicki explained. “That lets our team focus on what shouldn’t — the moments where human judgment makes all the difference.”

Because scale3PL’s systems are intuitive, new associates can learn them quickly. Training takes minutes, not days. Intuitive tools make adoption feel like relief and not resistance.

Your Move:

- Choose technology that’s intuitive and visual, so training becomes effortless.

- Use automation, including robotics and software systems, to support, not sideline, human expertise.

- Build cross-training programs that help people grow alongside your systems.

Turn Exceptions into Exceptional Experiences

Every warehouse has outliers of urgent orders, VIP shipments, or last-minute carrier cutoffs. The key is how quickly you can recover, and at scale3PL, those exceptions have become opportunities to build loyalty.

“Exceptions aren’t fires anymore,” Lawicki said. “They’re chances to win additional loyalty and trust.”

By automating the predictable parts of fulfillment, scale3PL gave its team the bandwidth to focus on these outliers. If there’s a late inbound order or a next-day air truck already at the dock, the team can act decisively because everything else is running smoothly. That agility has become a customer differentiator.

Your Move:

- Create visibility dashboards with real-time data from automation systems to flag exceptions instantly.

- Empower frontline teams to resolve issues without escalation.

- Track exceptions not as errors, but as metrics of responsiveness.

Build Systems That Flex at the Speed of Demand

Traditional warehouses rely on quarterly planning cycles, but Ever-Peak demands hourly responsiveness. scale3PL built flexibility into its operations — not as a feature, but as a discipline.

“Manual wins on day one,” Lawicki said, “but it loses by day ten. You need automation — software and mechanical — that can flex every single hour of every single day.”

This approach combines robotics, automated packaging, and warehouse management tools into a unified, adaptive ecosystem. Systems don’t wait for direction — they anticipate it with real-time data.

Your Move:

- Audit your operation for response time — how quickly can it flex up or down?

- Integrate systems so data flows seamlessly between automation layers.

- Use modular automation like Locus Robotics’ autonomous mobile robots (AMRs) that scale in increments, not leaps.

Design for Sustainability, Not Just Scale

Scaling fast is only valuable if it’s sustainable, and for scale3PL, that meant designing automation that improves both cost and culture.

“If our team has less friction, they can focus on exceptions — and that’s where value is created,” Lawicki said.

By integrating partners like Locus Robotics, Tension Packaging and Automation, and Deposco, the company built a fulfillment network that minimizes physical strain, reduces training time, and improves accuracy. The result is a more resilient workforce and a more stable business model that grows without burning out.

Your Move:

- Treat automation as an ongoing practice, not a one-time investment.

- Measure sustainability through retention, error rates, and customer satisfaction.

- Align every technology decision with your long-term operational health.

Final Takeaway

For successful Ever-Peak fulfillment, you need to sustain excellence when demand never stops, and the most successful 3PLs will be those that build automation around people, not the other way around.

As Lawicki put it:

“Automate the standard. Elevate the exceptions.”

That’s how fulfillment operations will scale smarter — not just through technology, but through balance.