WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Debunking the Top 7 Myths of Warehouse Robots

Mary Hart, Sr. Content Marketing Manager

Robots working in a warehouse isn’t the future. They’re here and they’ve been around for a while. In fact, the world’s first industrial robot was created in the United States back in 1962 by Unimation, and it was deployed in General Motors’ die-casting facility. Even with that background, warehouses, managers, and workers alike still have questions and misconceptions about warehouse robots and bringing them into a warehouse.

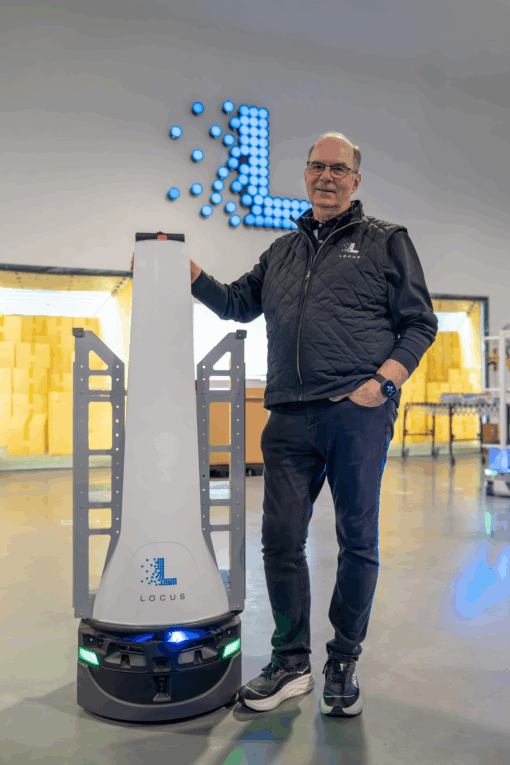

Some of the myths discussed below do hold true for various types of robotics systems, but for this blog post, we’re focusing on the myths about autonomous mobile robots (AMRs) from Locus Robotics including Locus Origin, Locus Vector, and Locus Max. Let’s take a look at them and uncover the truth about warehouse robots.

MYTH 1: AMRs can only be used for picking.

FACT 1: Warehouse robots like AMRs are much more versatile than their predecessors, like automated guided vehicles (AGVs). AMRs are being used successfully in every aspect of your warehouse, from receiving all the way through putaway and picking to packing and shipping. In receiving, LocusBots can be used to transport materials from one dock door to another or to the putaway area; in putaway, LocusBots do the walking and bring returned materials to the correct areas. For packing and shipping, there are a number of ways that LocusBots can help. With Locus Origin, the associates perform discrete picking to Origin, and then Origin delivers the items to a packing station.

With Locus Vector or Max, the robots can deliver materials to the packing stations. If the pallets are shipped out by Less than Truckload (LTL), Vector or Max can transport the pallet directly from the picking aisles. The pallet will be wrapped while it’s on the robot, and then Vector or Max can deliver it to the staging area where a forklift can concentrate its activities at the outbound loading dock. This process also increases safety by keeping human associates out of that area and keeping the forklifts in that area.

MYTH 2: AMRs are too small and you can only get work done with big carts.

FACT 2: Warehouse robots like AMRs run the gamut of payload size, with Locus Max able to carry up to 3,000 pounds. Our original bot, Locus Origin, can carry up to 80 pounds. The bigger carts are what warehouses know, but that doesn’t make them better. In fact, pulling or pushing those heavy carts leads to increased injury risk, according to the Canadian Centre for Occupational Health and Safety. The CCOHS states that these heavy carts increase the risk of toes, feet, and lower legs being bumped or crushed by the cart and strains in the back, shoulders, and arms. For successful warehouse operations, safety is important, and you can get the work done by big carts performed with even more efficiency through AMRs.

MYTH 3: AMRs can only be used on the main floor of a warehouse and not on mezzanines.

FACT 3: Real estate costs and space is an issue for many warehouses. If you can’t move to a new location with more square feet, you can instead do more with the small or enterprise-level space that you have with vertical fulfillment on multi-level or mezzanine levels. For the best results, you can (and should) have LocusBots on every level. Our robotics-enabled warehouse execution platform uses the multi-bot approach to optimize multi-level fulfillment speeds by orchestrating tasks, clustering picks, and initiating pick-and-pass directions for work that needs to be transported to a new level. For warehouses, the Locus software system works directly with your Warehouse Management System (WMS) to create a smart pick path for all of your products on every level throughout the building. Our pick and pass functionality supports discrete order picking from one floor to the other, and helps you manage the orders that go from one floor to the next.

MYTH 4: AMRs only work for Brownfield sites.

FACT 4. Warehouse robots like AMRs in the form of LocusBots are equally suited for current facilities, known as Brownfield sites, AND for brand-new facilities, known as Greenfield sites, alike. In fact, when you choose AMRs from Locus Robotics as your form of automation for your Greenfield site, you can run automation on your facility’s bare floor on day one, which can help you get your Greenfield sites operational and profitable quickly. From there, it’s just a matter of adding conveyors, multi-levels, and/or mezzanines as needed.

MYTH 5: AMRs are the warehouse robotics starter set and just for small companies.

FACT 5: Warehouse robots like AMRs work well in small warehouses and large, enterprise warehouses and fulfillment centers. Instead of starting out with just 10 LocusBots and seeing how that goes, many of our customers have already heard of or seen the proven results and want that efficiency for their operation by starting with 100 LocusBots or more.

AMRs also help by increasing your picking speed/velocity, and we’re not talking in the tens or hundreds of picks. Just look at iForce, which achieved 1 million picks in just 10 weeks after they brought on LocusBots in their same footprint with their current labor force.

MYTH 6: AMRs cost a lot in upfront money.

FACT 6: At Locus Robotics, we use the Robots-as-a-Service (RaaS) model. In this model, warehouses obtain our AMRs through a cloud-based subscription service instead of purchasing the robots outright. With RaaS, your facility’s automation costs shift from capital expenses (CapEx), which refers to major purchases that you plan to use for years, to day-to-day operational expenses (OpEx). The minimal initial investment creates a simpler budget approval process, dramatically shortens your time to ROI from years to months, and helps to free up the budget for other uses.

When your warehouse brings on autonomous mobile robots (AMRs) in a RaaS model, you are paying for the robots you need when your facility needs them. That could be during a normal peak season for your warehouse or when a lengthy special promotion is going out and you’re going to need more robots to help your human associates fulfill those orders.

MYTH 7: AMRs are taking jobs from workers.

FACT 7: Warehouse robots like AMRs work alongside human associates. They’re taking the place of the jobs that can’t be filled and do the mundane, physically exhausting work that humans shouldn’t have to do. For warehouse workers, there are many benefits of working with LocusBots, including the quick training time, but one of the top benefits is making their jobs less strenuous. Human associates in warehouses that don’t use AMRs may have to walk between 12 to 14 miles a day pulling a heavy cart. When a facility brings in our AMRs, the bots do the majority of the walking while the associates can stay in one section and focus on tasks that require a human brain.

With Locus Robotics, our AMRs shatter the myths of warehouse robots daily by providing increased efficiency results on day one, speeding up productivity, and improving employee retention.

Are you curious about how Locus Robotics can help your small or enterprise-level warehouse or fulfillment center improve productivity across the entire floor and mezzanines?

Talk to us and we’ll tell you more!"