WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Productivity is multiplying during Peak for 3PL sites with robots

Jeff Cody, Director of Interactive Marketing

The world is waiting to see how Peak 2020 will perform against predictions in this unpredictable economy. How, then, can we possibly start preparing for Peak 2021? Not even the best among us can predict what the consumer market will be like in a month, much less a year.

That’s exactly our point.

The best strategy is to prepare for the unexpected, and for 3PLs the key is warehouse automation. Autonomous warehouse robots have been a game-changer.

Betting big on the unexpected

DHL, USPS, FedEx, and UPS have all deployed the future-proofing strategies of warehouse automation prior to 2020. This race to automate has been accelerated in advance of this year’s Peak as delivery volumes increased by 20% from a year earlier for UPS and FedEx, and 50% for USPS.

The stress this year is not just about rapid delivery; 3PLs are adapting their facilities to best handle the flood of online orders leading up to the holidays due to brick-and-mortar sale declines caused by the pandemic. The key challenge is staying ahead of volume with a limited labor pool, and robotic warehouse automation has proven to be a successful extension of the workforce that multiplies the productivity of each worker. For 3PLs that have invested early in warehouse robots, it will prove to be a profitable year. For those that haven’t, Peak 2020 will be both a missed opportunity and a great time to start plans for warehouse automation in Peak 2021.

What is driving 3PLs to automate?

Warehouse automation has been a significant competitive advantage for 3PLs. The costs of implementing warehouse robots can be painful for their clients that have short-term contracts of 1-3 years, but the ROI comes back quicker when the costs are shared with other tenants in the facility. These clients may not have the opportunity to be early adopters, but they are eager second-generation adapters with high potential for growth.

Multi-tenant building capabilities

Multi-tenant building capabilities

3PLs are looking for automation solutions that can be shared between multiple or all tenants in a warehouse facility. They’re also expecting a seamless transition in the event of turnovers as contracts expire and new ones are signed.- Flexibility and scalability

Scalability is one of the most important factors to 3PLs for a solution because contracts and volumes change frequently. A flexible solution has the ability to scale up and down robot quantities for the throughput needed at any given time, ensuring there are no resources sitting largely underutilized for most of the year. - Time to productivity

Approaching peak hiring season, managers are concerned about the volatility of the labor market and the time it takes to train new workers. 3PLs are interested in solutions that require little training to get an associate up to full productivity sooner. Traditionally, a training period would include learning the scheme of the warehouse, its aisles, bays, and how RF devices work. Warehouse automation can reduce these difficult parts of training. - Cost management: Capital versus Operating expenses

Large capital expenses take time to approve and process, if the facility has it in the budget to make. It’s more palpable for 3PLs to allocate this expense to the operating budget, which sees month-over-month savings; instead of a single large purchase that depreciates over time, the facility can more accurately spread the value of warehouse automation over time and allow for flexibility when more robotic units need to be added. - Putaway

What are 3PLs, who’ve implemented robotic warehouse automation for picking tasks, looking to automate next? They are looking at putaway for restocks and returns, one of the slowest and least profitable functions. An automation investment that can do both picking and putaway functions provide a greater ROI. Allowing associates to task interleave seamlessly creates a harmonious workflow of inbound and outbound work with unparalleled task density.

Robotic automation solutions for 3PLs

Warehouse automation with robotic solutions requires a few short months of internal planning that can be further reduced by bringing warehouse automation providers to the table early on. Instead of planning for large structural and warehouse floor changes, today’s automation technology often requires zero infrastructure changes to install and integrates smoothly. Providers have their engineers and experienced productivity designers evaluate operations (often with highly proficient simulations) and are extremely committed to the success of the solution.

Large decision factors will narrow down the list of potential robotic warehouse solutions including cost, size, infrastructure requirements, and operational downtime during installation. For example, warehouse robots that run on a grid require massive infrastructure planning and changes, and in most cases cannot be installed in the same space that current operations are running.

Robotic arms can pick items effectively but cannot be the only solution implemented; they require a hybrid automation solution, working in tandem with conveyor belts and other robots or machines to fulfill orders, which is very costly. For these reasons, many companies are turning to a multi-bot solution that requires little infrastructure changes, can be installed in working operations, and multiplies the productivity of workers while returning an ROI within months instead of years.

The multi-bot solution

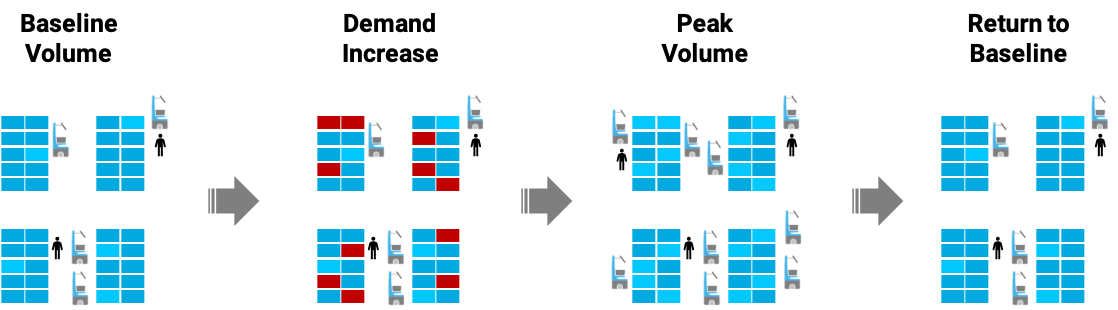

The multi-bot solution uses autonomous mobile robots (AMR) and runs on a Robots-as-a-Service (RaaS) model, essentially removing the up-front capital costs that cripple many plans to automate. Warehouses monitor their demand in real-time and place an order for additional robots when volume increases, then send them back to return to the baseline operation. The fleet of robots is also safe enough to operate in dense environments, fulfilling orders of various sizes/materials, or traveling narrow aisles to many locations.

A multi-bot solution is so flexible, it is capable of high performance in hybrid human-centric environments with full social-distancing cooperation as well as dark fulfillment centers. Being highly portable, it does not limit facilities to keep unbusy robots in a particular site as robots can be moved between multiple sites based on demand. This power of flexibility strengthens operations to weather through the most unexpected demand increases or changes; it future-proofs the entire operation.

Small and large 3PLs reap the benefits of a multi-bot solution to solve some of the most difficult problems including order accuracy, training, contract turnover, and limits in capital expenditure. Warehouse workers express positivity and excitement about their robot coworkers and experience improved personal job performance as their order accuracy reaches near-perfect rates. In current pandemic conditions, a multi-bot solution provides social distancing measures as part of its design, maintaining an operation’s high productivity while complying with health safety guidelines.

Watch what executives and managers are saying about the Locus multi-bot solution in their operations. IT integration teams from various companies also offer their perspectives on deploying a multi-bot solution.