WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Locus Robotics Introduces LocusONE, The Warehouse Orchestration Platform Powering Centrally Managed Multi-Bot AMR Automation

Data science-driven platform seamlessly orchestrates large fleets of multiple robot form factors in very large warehouses to deliver predictable, efficient, and scalable productivity results.

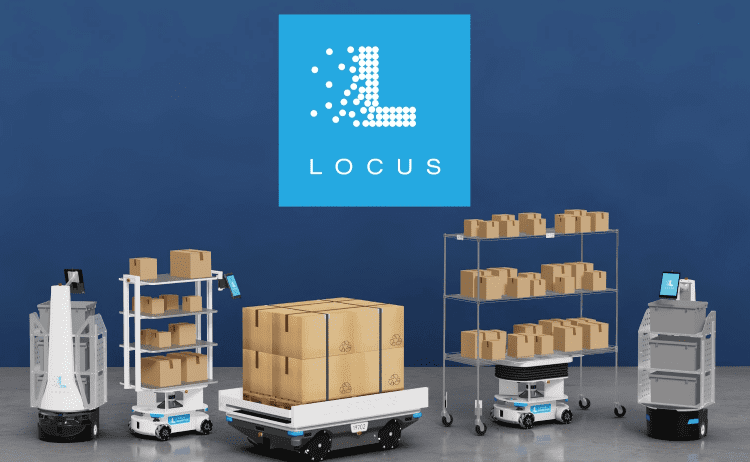

Locus Robotics, the leader in autonomous mobile robots (AMRs) for fulfillment warehouses, announces LocusONE, the industry’s first data science-driven warehouse automation platform to enable seamless operation and management of large quantities of multiple AMR form factors as a single, coordinated fleet in all sizes of warehouses. LocusONE uses proprietary data science to support

the full breadth of material movement needs found in today’s fulfillment and distribution warehouses.

“LocusONE makes it easy to deploy and manage large numbers of AMRs — and multiple form factors — within very large warehouses to work together as a single, orchestrated fleet,” said Rick Faulk, CEO of Locus Robotics. “Based on Locus’s proprietary data science engine, LocusONE enables operators to gain the flexibility and critical business intelligence needed to efficiently handle material payloads from 3 ounces to 3,000 pounds.”

The LocusONE platform supports a thousand or more robots, operating in sites as large as one million square feet or more, executing multiple use cases simultaneously in a single, intelligent, and orchestrated solution. With LocusONE, LocusBots engage in a diverse array of tasks — including each picking and putaway, case picking and putaway, replenishment, pallet building, routine routes, point-to-point transport, counting, and more — within a single warehouse. The data science behind the scenes optimizes the mix of tasks throughout the day to achieve optimal warehouse productivity.

LocusONE integrates with any WMS system to provide flexible and dynamic fleet management and enables easy deployment of a mix of Locus Origin, Vector, and Max AMRs tailored to meet each warehouse’s specific needs. Regular enhancements are released as over-the-air updates to Locus’s installed base of more than 250 customer sites.

“Locus lets DHL Supply Chain deploy the right bot for our customers’ varied needs, all centrally coordinated and managed on one platform. With Locus’s powerful data science strategy, delivered through the LocusView dashboards, LocusONE plays an important role in providing the key business intelligence insight we need to optimize operational efficiency and improve service quality for our customers,” said Sally Miller, CIO North America & DSC Digital Transformation Officer of DHL Supply Chain North America. “Partnering with Locus has helped us deliver on our commitment to continuous innovation and digital transformation across the entire supply chain”.

Locus’s powerful data science foundation makes it possible to smoothly navigate hundreds – or even a thousand or more – bots in a single footprint as well as deliver predictive and actionable management guidance – in real time – to dramatically improve throughput across a multitude of use cases. LocusONE includes Locus’s award-winning LocusView package, which delivers data-driven, actionable insights across more than two dozen insightful reports and real-time dashboards, including labor guidance, predictive insights for work completion, operational comparisons against targets or time periods, order pool tracking and guidance, mission analysis and optimization, key performance visualization, and more.

LocusONE further extends Locus’s position as the industry’s AMR leader for automation and digitalization of warehouses, distribution, and fulfillment centers to efficiently meet increasing order volumes, labor shortages, and rising consumer expectations.

“As warehouses become increasingly complex, the ability to rely on a dependable data analytics strategy is essential to their smooth operation. Having the ability to deploy a flexible, seamless and proven AMR management platform to meet a broad range of use cases has become a must-have in the warehouse fulfillment industry,” said Ash Sharma, Senior Research Director at Interact Analysis. “This innovative platform demonstrates how critical multi-form factor interoperability is in today’s fulfillment warehouse and reflects Locus Robotics’ commitment to innovation, ease of use, and broad industry vision over the past few years.”

“LocusONE’s ability to integrate rapidly and efficiently with other automation technology – such as sortation or packaging systems – ensures that a nimble, scalable robotics solution can be easily deployed into both brownfield and greenfield environments”, noted Faulk.

“The LocusONE platform enables Kenco to create a seamless fulfillment experience that delivers enhanced productivity, while improving employee morale and visibility. We rely on the LocusView dashboards to monitor progress and inform our labor management throughout the day,” said Kristi Montgomery, Vice President, Innovation, Research & Development Kenco Logistics. “LocusONE’s real-time insights allow us to delight our customers, and that’s what matters most to Kenco.”

LocusONE is available through the company’s all-inclusive, Robots-as-a-Service (RaaS) business model. Locus Origin, Vector, and Max can be easily added to existing and new workflows, enabling operations to dynamically scale and adapt to changing market demands. In a study done by Peerless Research Group, nearly half of respondents said they would prefer to buy their robotics solution as an entire integrated system that includes hardware, software, support, and maintenance.

Locus’s Recycle, Refurbish, and Repurpose initiative is the first in the AMR industry to actively drive sustainability across all aspects of the business — from manufacturing and deployment to support and maintenance — at sites around the world. Locus is continually working to identify and implement best-practice strategies and tactics designed to reduce overall waste across all areas of our organization.

About Locus Robotics

Locus Robotics’ revolutionary, multi-bot solution incorporates powerful and intelligent autonomous mobile robots that operate collaboratively with human workers to dramatically improve piece‐handling, case-handling, and pallet-moving productivity 2X–3X, while optimizing labor and making efficient use of warehouse space. Locus helps retailers, 3PLs, and specialty warehouses efficiently meet and exceed the increasingly complex and demanding requirements of fulfillment environments. Easily integrating into large-scale new and existing warehouse infrastructures without disrupting workflows, Locus transforms productivity without transforming the warehouse.

Headquartered in Wilmington, Massachusetts, Locus’s EMEA presence is centrally located in Amsterdam, with APAC presence located in Singapore.

In 2022 alone, Locus Robotics has won more than 17 industry awards, including being named to the Inc. 500 for the second year in a row and a 2022 IFOY Award for its Autonomous Mobile Robot Solution in the Automated Guided Vehicle (AGV/AMR) category.

Headquarters Location: U.S.A.