Recapping ProMat and LogiMat 2025, Locus Robotics previewed Array, introduced R2G automation, and showcased AI-powered fulfillment systems that redefine flexibility, speed, and efficiency in warehouse operations.

Get a preview of Array, the industry’s most advanced AI-powered, zero-touch fulfillment system for warehouse automation.

Discover how AI and data analytics are transforming warehouse operations. Learn from Barrett Distribution Centers’ Derek Morse about optimizing inventory, reducing costs, and overcoming data challenges in modern warehousing.

Optimize warehouse efficiency with real-time data. Learn how live metrics improve decision-making, prevent bottlenecks, and balance labor with automation.

Locus Robotics celebrates International Women’s Day by recognizing women in leadership. Learn how we foster an inclusive workplace, empower women to lead, and drive industry-wide change in warehouse automation.

Discover how warehouse automation eliminates bottlenecks, boosts productivity, and enhances workforce efficiency. Learn how flexible automation drives real results and helps warehouses scale dynamically.

Discover how AI-driven robots and forklifts can safely collaborate in warehouses. Learn how Locus Robotics uses machine learning for smarter navigation, reducing congestion, and improving efficiency.

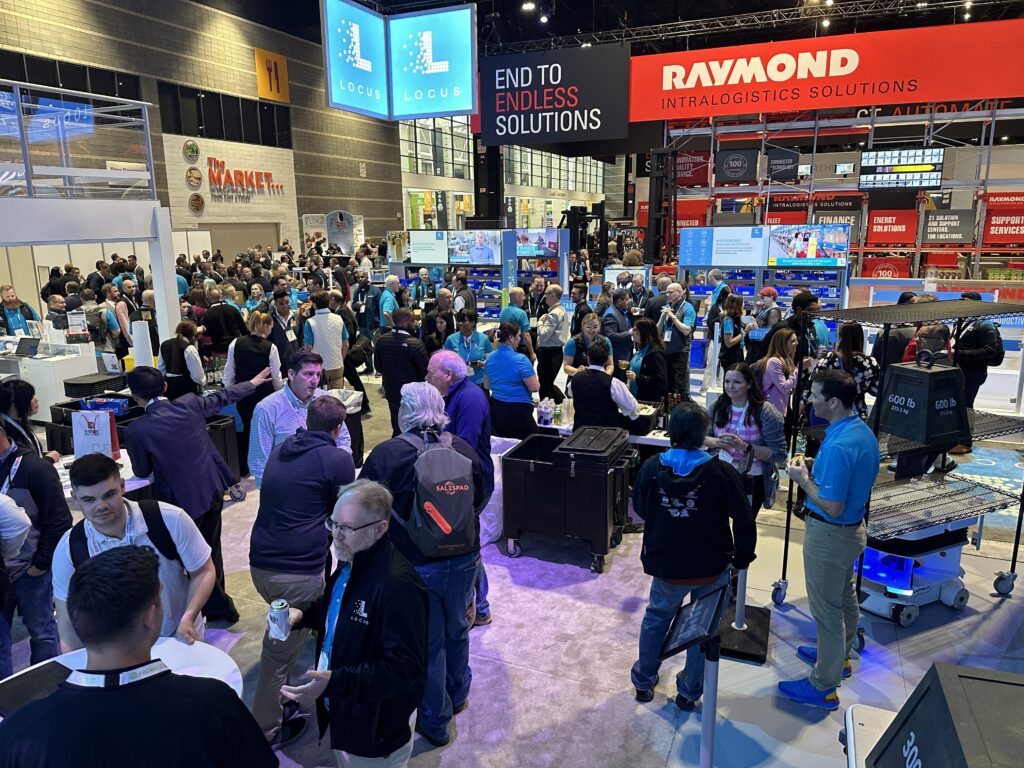

Discover the latest in warehouse automation at ProMat 2025! Visit Locus Robotics at Booth #S2703 for live demos, expert insights, and must-attend sessions on robotics, AI, and logistics innovation.

Discover how opportunity cost impacts warehouse automation decisions. Learn the hidden costs of maintaining manual processes and why automation can drive cost savings, performance gains, and long-term scalability.

Discover five ways warehouse automation optimizes operations, from boosting speed and accuracy to increasing throughput. Learn how data-driven automation improves efficiency, reduces costs, and prepares warehouses for peak seasons.

P2G automation offers warehouse CFOs faster ROI, financial flexibility, and risk mitigation compared to ASRS and G2P solutions. Discover why scalable, cost-effective robotics are the smarter choice for warehouse efficiency.

Retail warehouses use AI and robotics to enhance efficiency, improve employee experience, and meet customer expectations. Learn how Fragrance.com leverages automation for scalability and competitiveness.

Flexible automation empowers warehouses to scale, optimize labor, and adapt to demand shifts seamlessly. Learn how agility drives efficiency and resilience in modern warehouse operations.

Smart warehouses powered by AI, robotics, and data analytics drive efficiency, flexibility, and scalability. Discover why this is a pivotal year for warehouse transformation.

Protect your data this Data Privacy Day! Learn key personal and organizational steps to enhance privacy, security, and compliance. See how Locus Robotics prioritizes data protection.

Locus Robotics celebrates the milestones of customers that achieved record picks and streamlined operations with warehouse automation. Discover how these partnerships redefined warehouse efficiency and productivity.

Discover how mezzanines optimize vertical warehouse space with automation, boost efficiency, and future proof operations. Learn design tips and best practices from the “Warehouse Automation Matters” podcast.

Explore key strategies for warehouse automation in 2025: flexibility, throughput, and intelligence. Learn how to optimize operations with mobile tech, AI-driven insights, and scalable solutions. Part 3 of 3.

Discover how warehouse automation enhances flexibility, efficiency, and safety to tackle post-holiday returns. Learn strategies from nGroup leaders on optimizing 3PL and retail putaway operations for long-term success.

Discover 10 key warehouse automation trends for 2025, including mobile robotics, AI-driven insights, and RaaS. Learn how these innovations will shape the future of logistics and supply chain operations.

Explore the top warehouse automation milestones and trends, including AI-driven solutions and human-robot collaboration, and discover innovations shaping the future of logistics. Part 1 of 3.

Learn how Fast Pick by Locus Robotics enables unlimited warehouse throughput with P2G flexibility. Streamline bulk and high-demand picking for faster, scalable, and efficient fulfillment tailored to dynamic operational needs.

Discover how modern warehouse automation enhances efficiency beyond picking. From case handling to data-driven insights, explore flexible, scalable solutions for your warehouse operations.

Explore data-driven complex warehouse cartonization, sustainability, and holiday cheer from a licensed Santa Claus.

Stay ahead with the latest warehouse automation trends for eCommerce, from Warehouse Execution Systems to autonomous mobile robots. Check how to optimize inventory and boost efficiency with advanced automation technology.

Master peak season with top eCommerce strategies: boost efficiency, manage labor, leverage AMR automation, and optimize inventory to meet high demand and consumer expectations seamlessly in your warehouse.

Explore the spooky side of outdated warehouses with manual processes and fixed automation! Discover how LocusBots can eliminate inefficiency and labor shortages, turning warehouse nightmares into productivity dreams this Halloween.

Explore how the rise of online pharmacies is reshaping logistics, from cold chain management to drone deliveries. Hear insights from Guy Courtin of Tecsys on how the pharmaceutical industry is adapting to these new supply chain challenges.

Discover the top warehouse automation trends for 2025, including collaborative robotics, AI-driven optimization, scalable automation, and sustainability initiatives, as industry experts share insights on how these innovations are transforming the future of warehouse operations.

Debunk common warehouse automation myths, from job replacement fears to high costs. Learn how automation enhances job satisfaction, is flexible, scalable, and delivers rapid ROI while empowering your workforce and boosting efficiency.

Discover how right-sized packaging reduces costs, boosts warehouse efficiency, and supports sustainability. Learn from Paccurate’s Greg Walls on how packaging automation is transforming modern warehousing by optimizing carton sizes and minimizing waste.

Start your warehouse automation journey with expert insights from Andy Johnston of GEODIS. Learn how to identify key challenges, assess readiness, and find the right partners to implement effective automation solutions.

Discover how 3PL Fulfillment is evolving with automation. Learn from DHL’s insights on integrating robotics for increased efficiency, improved worker satisfaction, and scalable solutions to meet peak demand in the logistics and supply chain industry.

Discover how AMRs are designed for simplicity, ease of use, and seamless integration, debunking myths about complexity and showcasing their benefits for warehouses of all sizes, from small operations to large enterprises.

Discover how AMRs offer scalable, flexible, and cost-effective automation solutions for warehouses of all sizes, delivering rapid ROI, increased productivity, and enhanced operational efficiency while working alongside human workers for a more efficient operation.

Explore the future of warehouse automation with insights from industry leaders on robotics, AI, and collaborative technology trends. Discover how to choose the right tools and scale operations for success in a competitive landscape.

Learn strategies to manage diverse inventory, fulfill orders quickly, and leverage AMRs to enhance productivity during back-to-school and holiday rushes, ensuring seamless transitions between these critical shopping periods.

Gain insights on preparing your warehouse for peak season with expert advice on planning, technology use, and empowering human workers. Learn strategies to streamline operations, maintain service levels, and tackle the challenges of increased order volumes effectively.

Discover how warehouse automation with robots is easier than you think. Learn about seamless integration, flexibility, and rapid ROI with AMRs, enhancing efficiency and worker satisfaction in your warehouse.