WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Must-Have WMS Features for Today’s Automated Warehouse

Amit Levy, EVP of Sales and Strategy, Made4net

Warehouse Management Systems (WMS) are no longer just about managing inventory and printing pick tickets. In this high-velocity, automation-driven environment, a top-tier warehouse management system must be the digital control tower for the entire warehouse that is capable of orchestrating labor, inventory, and increasingly, fleets of robots and automated systems.

The days of buying WMS solutions solely for barcoding and basic inventory tracking are behind us. To compete in a world defined by same-day delivery expectations, labor shortages, and relentless SKU proliferation, warehouse leaders need intelligent, real-time systems that can adapt, scale, and tightly integrate with emerging technologies.

Here are 7 modern, must-have WMS features every advanced operation should look for:

- Deep Integration with Warehouse Automation and Robotics

- Real-Time Task Collaboration, Orchestration and Interleaving

- Advanced Labor Management and Workforce Optimization

- Omnichannel Execution and Multi-Workflow Flexibility

- Configurable, Modular Architecture Built for Speed and Scale

- Cloud-Native Deployment with Enterprise-Grade Security and Reliability

- Actionable Analytics and Embedded Intelligence

Deep Integration with Warehouse Automation and Robotics

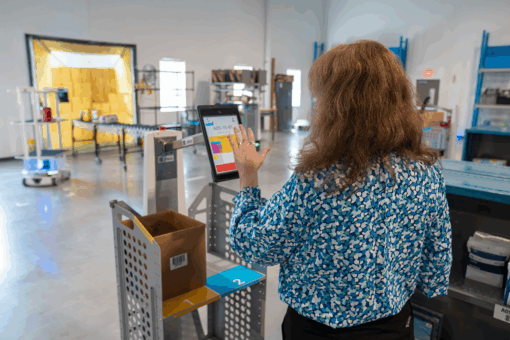

As more organizations deploy Autonomous Mobile Robots (AMRs) from Locus Robotics; automated storage and retrieval systems (AS/RS); conveyor systems; and put walls, the ability of a WMS to seamlessly connect with this ecosystem is essential.

A modern WMS must offer basic data exchange as well as built-in connectors to popular material handling equipment (MHE) systems, robust integration frameworks (like APIs and event-based messaging), and the flexibility to adapt to new automation technologies as they emerge. These capabilities create a unified foundation where machines and systems operate in sync, setting the stage for dynamic task coordination and warehouse-wide orchestration.

Real-Time Task Collaboration, Orchestration, and Interleaving

Top-performing WMS platforms go beyond task assignment to act as intelligent command centers, orchestrating real-time collaboration between human workers and robotic systems.

Task engines within the WMS dynamically allocate work based on factors like worker proximity, robot availability, workload balance, and shifting warehouse priorities. This enables intelligent task interleaving, where travel paths and idle time are minimized, and every movement — whether by a picker, a Locus Robot, or both working together — is optimized for productivity.

Advanced Labor Management and Workforce Optimization

In a tight labor market, optimizing every worker's output is non-negotiable. Today’s WMS must offer labor tracking, embedded labor standards, engineered metrics, predictive scheduling, and dynamic workload balancing. Sophisticated labor management systems even deliver real-time feedback and gamification tools to keep teams engaged and motivated.

These features work to improve throughput, help reduce overtime, increase employee retention, and align performance with strategic KPIs.

Omnichannel Execution and Multi-Workflow Flexibility

One warehouse. Many channels. That’s the new norm, and it’s putting pressure on traditional fulfillment models. Whether you're shipping direct-to-consumer (D2C), replenishing retail stores, fulfilling wholesale orders, or handling returns, your WMS needs to support multiple workflows simultaneously without missing a beat.

Omnichannel execution requires a high degree of flexibility, enabling the system to manage different order types, service levels, and handling requirements, all from the same inventory pool. And as order volumes and complexity grow, automation becomes a necessity.

Automated solutions like AMRs, person-to-goods (P2G), goods-to-person (G2P) systems, and put walls help speed up order processing and reduce errors in high-volume, high-SKU environments. The WMS must not only support these technologies but also orchestrate them effectively, dynamically assigning tasks and adjusting workflows in real time to meet aggressive service level agreements (SLAs).

Configurable, Modular Architecture Built for Speed and Scale

Modern supply chains are anything but static, and leading WMS must be built on modular, microservices-based architecture to keep up with constant change, whether it’s a new facility, automation upgrade, or SKU expansion.

A well-architected WMS is like a flexible brain as it adapts, responds, and grows with your operation. Technical agility is just as important as functional depth.

Configurability is key, so look for systems with no-code / low-code tools that empower internal teams to adjust workflows, screens, and rules without waiting on IT or external support.

Cloud-Native Deployment with Enterprise-Grade Security and Reliability

Cloud-based WMS software offers major advantages in uptime, scalability, cost control, and cybersecurity. Whether multi-tenant or single-tenant SaaS, cloud deployments eliminate the burden of infrastructure management and enable faster time-to-value, often in weeks instead of months.

Additionally, leading providers deliver robust disaster recovery, data redundancy, and encrypted access controls, which are critical for both compliance and peace of mind.

Actionable Analytics and Embedded Intelligence

What good is data if it’s not actionable? Top WMS platforms now include real-time dashboards, predictive analytics, and machine learning algorithms that surface opportunities for improvement before they become problems.

Whether it’s forecasting labor needs, flagging inventory discrepancies, or analyzing picking efficiency by zone, your WMS should empower you to continuously improve operations with data-driven decisions.

Future-Ready WMS Recommendations

Selecting the right WMS starts with aligning the system’s capabilities to your strategic goals and not just your current pain points. Whether you're adopting robotics, consolidating channels, or scaling into new markets, you need a solution that’s ready to evolve with you.

Made4net’s WarehouseExpert WMS was designed with this future in mind. It delivers core WMS functionality alongside advanced capabilities such as real-time automation orchestration, task interleaving, intelligent labor management, and omnichannel execution. Built on a flexible, Microsoft-based technology stack, it’s ideal for operations that demand configurability, scalability, and seamless integration with MHE, robotics, and best-in-class supply chain partners like Locus.

Ready to modernize your warehouse?

Talk to a Made4net expert today and learn how WarehouseExpert can power your next phase of growth.

BIO:

As Executive Vice President of Sales & Strategy, Amit Levy is responsible for developing and leading the overall sales strategy for Made4net products, as well as overseeing partnerships and building growth strategy. Levy brings over 25 years of experience managing sales and implementations of supply chain execution software throughout global markets.