WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Top Tips for Managing Warehouse Heat and Keeping Cool

Mary Hart, Sr. Content Marketing Manager

As a heat wave sweeps the United States, warehouse heat becomes more than an inconvenience — it impacts worker efficiency and safety. While air conditioning and proper ventilation are traditional methods to cool a warehouse, innovative solutions can significantly enhance these efforts.

According to the Bureau of Labor Statistics (BLS), the incidence of heat-related illnesses and injuries in warehouses is a critical concern. Heat stress can lead to a range of health issues, from heat exhaustion to heat stroke, which can be fatal if not properly managed. The emphasis on addressing these hazards highlights the importance of proactive measures to ensure your associates’ safety during extreme heat conditions

Here are some effective strategies for maintaining a cooler warehouse environment during extreme heat.

Top Airflow Management Tips

An effective approach to cooling a warehouse involves optimizing airflow through strategic ventilation management.

- Strategic Placement of Fans and Vents: Use large industrial fans and exhaust systems to create a cross-ventilation effect. This method ensures that hot air is pushed out while cooler air is drawn in, maintaining a steady flow of air throughout the warehouse.

- High Volume Low Speed (HVLS) Fans: These large ceiling fans move large amounts of air at low speeds, creating a gentle, consistent breeze that can significantly reduce perceived temperature and improve overall air circulation.

- Natural Ventilation: Utilize windows, skylights, and vents to harness natural airflow. Opening these during cooler parts of the day and closing them when the outside temperature rises can help maintain a comfortable indoor environment.

- Air Curtains: Install air curtains at loading docks and other frequently opened doors to prevent hot outside air from entering the warehouse while maintaining a barrier of cool, conditioned air inside.

Reduce Heat Generation with Efficient Task Management

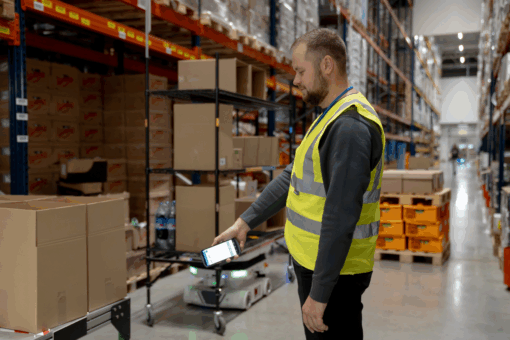

Cooling the air is essential, but reducing heat sources is equally important. AMRs can streamline tasks, minimizing the heat generated by equipment and human activity. By handling the more intensive tasks of transporting orders through your warehouse, AMRs reduce the need for forklifts and other heavy machinery that often generate significant heat during operation. Plus, they lessen the burden of walking for your associates, keeping them from overheating. This reduction in heat sources contributes to a cooler overall environment.

Smart Scheduling to Beat the Heat

If you know when the heat will be at its worst, you can schedule more labor-intensive tasks for the cooler periods, reducing overall heat stress on your associates. This approach ensures that associates are not overexerted during peak heat times, and can spend that time on less labor-intensive work. When you bring AMRs into your warehouse, this isn’t necessary as AMRs take on labor-intensive tasks.

Cooling Stations and Hydration Reminders

Integrating cooling stations within your warehouse is crucial, especially during a heat wave. These stations, strategically placed, ensure that associates have regular access to hydration and a chance to cool down. Or you could be creative and mount a cooler to a scooter to wheel it around to associates. Providing fans, misting systems, and shaded rest areas at these stations can also help associates lower their body temperatures effectively. Regular hydration breaks should be encouraged, and water stations should be easily accessible throughout the warehouse. Encouraging a culture where taking hydration breaks is normalized can significantly reduce the risk of heat-related illnesses.

Eco-Friendly Cooling Solutions

Sustainability is important for the environment, and it should extend to cooling methods in your warehouse. Integrating eco-friendly cooling technologies such as solar-powered fans or evaporative coolers can provide an environmentally conscious way of reducing warehouse temperatures. Solar-powered fans, for example, can help reduce electricity costs while providing necessary ventilation. Evaporative coolers, which use water to absorb heat from the air, can be particularly effective in dry climates, providing a natural and energy-efficient cooling method. These solutions not only aid in maintaining a cooler environment but also align with a commitment to sustainable warehouse operations.

Temperature Monitoring

When heat waves happen, it’s important to monitor the temperature in various sections of the warehouse and respond accordingly. Thermostats or other temperature sensors should be placed throughout the warehouse for real-time data, allowing for immediate action when temperatures rise above safe levels. This proactive approach can prevent heat-related issues before they become serious problems, ensuring a consistently safe working environment.

6 Traditional Ways to Cool Your Warehouse

In addition to the advanced strategies involving robotics, several traditional methods can help maintain a cooler warehouse environment:

- Insulation and Reflective Roofing: Proper insulation can significantly reduce the amount of heat entering your warehouse. Reflective roofing materials can reflect sunlight away, reducing the overall temperature inside. These methods are effective in preventing the buildup of heat and maintaining a more stable indoor climate.

- Ventilation: Proper ventilation is crucial. Installing large fans, exhaust systems, and vents can help circulate air and remove hot air from the warehouse. Cross-ventilation, where air enters from one side of the warehouse and exits from the other, can be particularly effective in promoting airflow and reducing indoor temperatures.

- Portable Air Conditioning Units: While installing a full-scale HVAC system might be cost-prohibitive, portable air conditioning units can provide targeted cooling in areas where associates are most active. These units can be moved as needed to provide relief in different parts of the warehouse, ensuring that associates stay cool throughout their shifts.

- Shade and Outdoor Cooling: For warehouses with outdoor areas, creating shaded zones with canopies or awnings can provide your associates with a place to cool down. Adding misting systems or portable fans in these areas can further enhance the cooling effect, offering associates a respite from the heat.

- Heat-Reflective Paints and Coatings: Applying heat-reflective paints or coatings to the exterior of the warehouse can help reduce the amount of heat absorbed by the building. These coatings are designed to reflect a significant portion of solar radiation, keeping the interior cooler and reducing the need for additional cooling measures.

- Employee Training and Awareness: Educating associates about the risks of heat-related illnesses and the importance of staying hydrated and taking breaks can empower them to take proactive steps in managing their health. Regular training sessions can reinforce the importance of these practices, ensuring that associates are aware of the best ways to stay safe during extreme heat.

A Cooler, Smarter Warehouse

Maintaining a cool warehouse is not just about comfort — it’s about safety, efficiency, and productivity. Combining advanced technological solutions with traditional cooling methods can create a comprehensive approach to managing your warehouse temperatures. From optimizing ventilation with strategic air flow management to implementing eco-friendly cooling solutions, and having AMRs take on labor-intensive tasks during all seasons, these strategies ensure that warehouses remain conducive environments, even in the heat of summer.

By integrating these innovative approaches, you can ensure that your warehouse stays cool, efficient, and associate-friendly, no matter how high the mercury rises. Ready to beat the heat and learn how Locus Robotics’ solutions can cool down your warehouse associates? Let’s talk!