WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

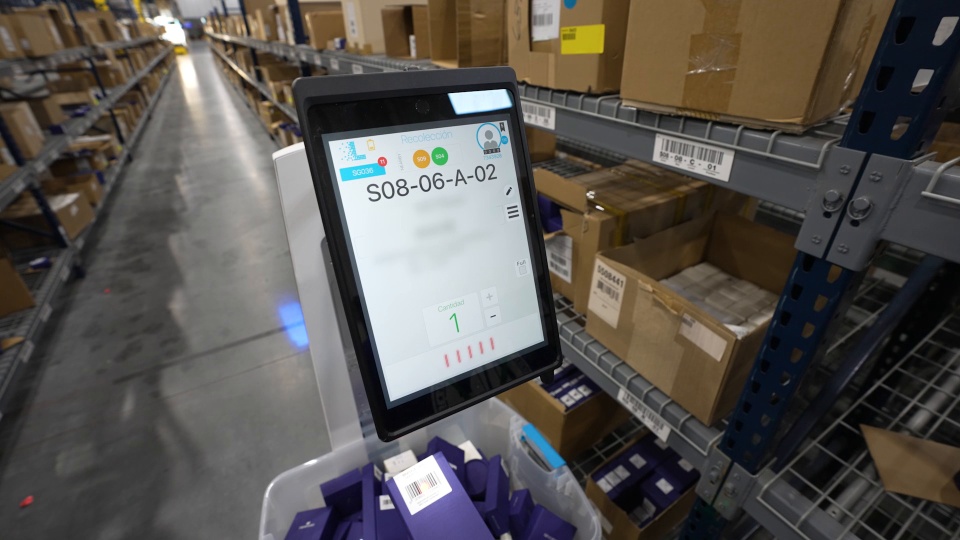

Case Study: UPS

UPS doubles productivity with Locus Robotics

To increase pick, pack, and ship speeds to meet exploding demand, UPS automated their fulfillment process with Locus Robotics. Productivity increased from 40-45 lines per hour (LPH) to 80-90 LPH with the LocusBots and close to 100 LPH in some cases.

With Locus, UPS was able to meet their strict international cut off times, while also positively motivating their warehouse associates, who liken working with the bots to a computer game.