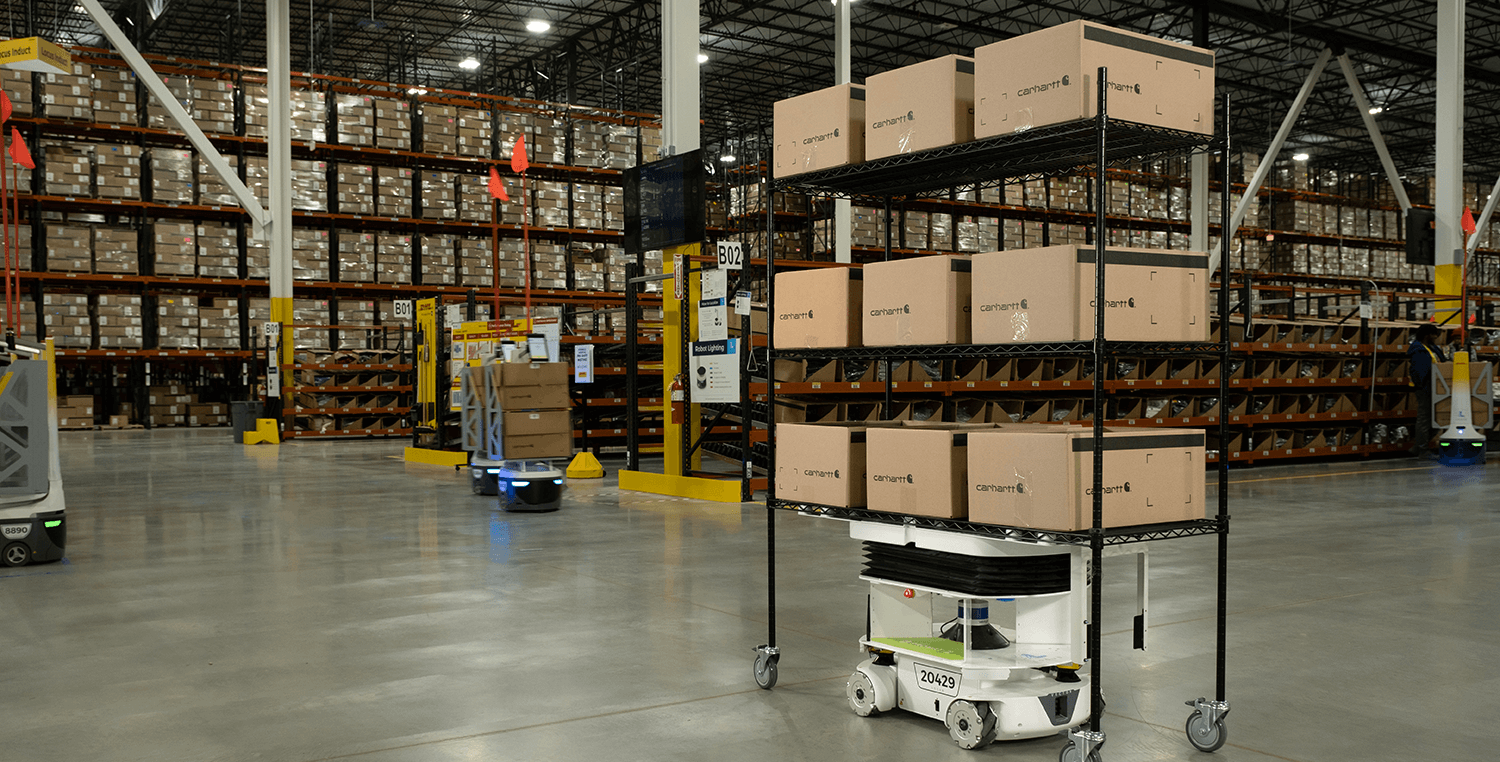

WP: How to achieve 400 UPH with Locus Fast Pick

The Power of Interleaving Warehouse Workflows

Locus Putaway is, in its simplest form, reverse warehouse picking. During

putaway, a warehouse associate takes an item and puts it back into a

bin rather than picking an item out of the bin. Simultaneously pick orders, manage returns, and replenish your warehouse pick space using the same robotic technology.