WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

Resources

ResourcesWarehouse Automation Content

No results found

Warehouse Automation Matters | Episode 31 - From Film Reels to Fulfillment Robots

Explore how Conectiv evolved from Technicolor roots into a flexible 3PL using fulfillment robots, data, and automation to support diverse industries from media to medical products.

On-Demand Webinar: SupplyChainBrain Practical Uses of AI in the Warehouse

Discover how practical AI warehouse solutions drive measurable ROI. Learn real-world applications of AI in picking, orchestration, and labor optimization from Locus Robotics’ Neil Bentley.

The Warehouse Efficiency Playbook

Discover proven strategies from leading fulfillment experts. The Warehouse Efficiency Playbook shows how to scale automation, empower teams, and build long-term warehouse resilience.

Staples Canada Case Study

Discover how Staples Canada modernized fulfillment with Locus Robotics, doubling productivity, improving order accuracy by 73%, and cutting training time by 70% through flexible, scalable warehouse automation.

Warehouse Automation Matters | Episode 30 - Ever-Peak and 3PL Warehouses

Discover how scale3PL automates fulfillment to handle “Ever-Peak” demand year-round. VP of Strategy Adam Lawicki shares how automation, accuracy, and customer experience drive growth in modern 3PL operations.

Warehouse Automation Matters | Episode 29 - Beyond Price: Choosing the Right 3PL Partner

Learn what defines a successful 3PL partner as Barrett Distribution’s Bryan Corbett joins Warehouse Automation Matters to discuss culture, trust, and when to introduce warehouse automation.

On-Demand Webinar: Practical Uses of AI in the Warehouse

Learn practical examples of how leading warehouses organizations use AI to improve productivity, flexibility, and scalability.

S&S Activewear

Discover how S&S Activewear increased throughput by 50%, halved training time, and improved employee safety with Locus Robotics’ record-fast 49-day AMR deployment.

All About Warehouse Peak Season eBook

Learn how warehouse automation helps you handle peak season with ease to boost throughput, reduce labor strain, and scale operations with AI-driven robotics.

Warehouse Automation Matters | Episode 28 - The Soft Benefits and ROI of Warehouse Automation

Discover how warehouse automation delivers rapid ROI, higher accuracy, and soft benefits like employee satisfaction in this conversation with Peak Technologies' leaders on Warehouse Automation Matters.

The Evolution of Warehouse Robots

Explore the evolution of warehouse robotics, from early industrial robots to AI-powered fleets, and see how automation drives flexibility, throughput, and efficiency for modern fulfillment operations.

On-Demand Webinar: From Pen to Paper - Staples Canada Robotic Rollout

Discover how Staples Canada scaled robotics across its national warehouse network. Learn from Mert Selcuk and Locus Robotics on AMRs, WMS, workforce engagement, and throughput gains.

Warehouse Automation Matters | Episode 27 - 10 Million Picks and Counting

Discover how KSP Fulfillment reached 10 million picks with warehouse automation, improving labor stability, scaling operations, and enhancing employee experience through robotics and continuous improvement.

Checklist: Is Your Warehouse Peak-Ready? A Strategic Checklist for Smarter Automation

Prepare your warehouse for peak season with this strategic checklist. Identify stress points, assess labor and tech gaps, and plan automation for resilient, scalable operations.

Warehouse Automation Matters | Episode 26 - Rolling Out Robots the Radial Way

Radial’s David Welsh shares how scaling fulfillment robots across multiple sites improves training, workforce adoption, and consistency in warehouse operations on the Warehouse Automation Matters podcast.

Warehouse Automation Matters | Episode 25 - Automation with a Human Touch

Discover how human-centric leadership, flexible systems, and warehouse automation help Motivational Fulfillment drive efficiency, retention, and real-time decision-making across operations.

Motivational Fulfillment Delivers Higher Picks with Locus Robots

Discover how Motivational Fulfillment boosted productivity by 61% and cut labor needs by 20% using Locus Robotics to deliver faster picks, higher accuracy, and improved associate safety across multiple sites.

Verify Everything Research Report

Explore how Zero Trust Architecture strengthens warehouse cybersecurity. This research report from Locus Robotics' security leader covers risks, best practices, and strategies for securing automated fulfillment environments.

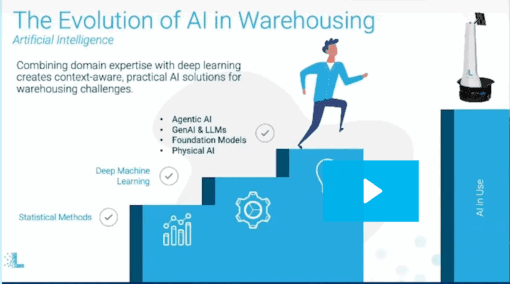

Warehouse Automation Matters | Episode 24 - Real AI for Real Warehouses

Explore how Locus Robotics uses physical, trustworthy, and holistic AI to optimize warehouse operations, improve throughput, and deliver real ROI. Featuring Oscar Mendez, Head of AI.

On-Demand Webinar: Flexibility on Warehouse Front Lines

Discover how top warehouses stay agile under pressure. This on-demand webinar explores real-world lessons in flexibility, scalable throughput, and avoiding the density trap with Locus Robotics.

Warehouse Automation Matters | Episode 23 - LCAP and Warehouse Automation Explained

Discover how LCAP helps modernize warehouse operations. Datex leaders Bryan Batchelder and Dave Castanon join Warehouse Automation Matters to share real examples of low-code platforms transforming warehouse agility and ROI.

Warehouse Automation Matters | Episode 22 - Make Smarter WMS Decisions

In this episode of Warehouse Automation Matters, Amit Levy of Made4Net and host Mary Hart discuss the integration of automation in warehousing, emphasizing the importance of collaboration between warehouse managers and IT, the role of AI and machine learning, the necessity of mapping current processes for efficiency, and the critical aspects of selecting the right partners for warehouse solutions.

Dental City Automates Warehouse Fulfillment with Locus Robots

Discover how Dental City increased picking productivity by 300% and achieved 99% order accuracy by automating fulfillment with Locus Robotics’ AMRs, without expanding their warehouse footprint.

AI in the Warehouse eBook

Explore how AI is transforming warehouses with physical, explainable, and holistic intelligence to boost productivity.

Warehouse Automation Matters | Episode 21 - Right-Sized Packaging and Warehouse Automation

In this episode of Warehouse Automation Matters, host Mary Hart spoke with Bryan Boatner, Global Managing Director of Automation at Ranpak, on the importance of automation in warehouse operations with a focus on right-sized packaging, waste reduction, and the role of data in optimizing processes.

Warehouse Automation Matters | Episode 20 - Navigating the Automation Landscape

In this episode of Warehouse Automation Matters, Mary Hart interviewed Mert Selcuk, Senior Manager of Supply Chain Strategy and Capabilities at Staples Canada. They discussed the warehouse automation landscape and focused on the implementation challenges, strategies, and technologies involved.

Life After Deployment: Unlocking Continuous Warehouse Optimization

Optimization and Solution Design (OSD) team helps customers get the most out of their Locus fleet long after the initial deployment.

Case Study Deep Dive: How Automation is Changing the Warehouse

Over half of fulfillment centers worldwide are now embracing some form of automation as a strategy to enhance efficiency, productivity, and overall operational resilience.

Flexible Warehouses: The Case for AMRs in Modern Warehousing

You’ll learn why warehouses need flexibility to adapt to fluctuating demands due to changes in volume, product lines, or distribution channels.

Warehouse Automation Matters | Episode 19 - 3PL Fulfillment Lessons from the Front Lines

In this episode of Warehouse Automation Matters, Mary Hart interviewed Chris Caouette, Chief Revenue Officer at North Bay Distribution, on challenges and innovations in the 3PL and e-commerce fulfillment space.

MAERSK

Peak season and higher volumes from end customers led Maersk to look for a new solution that didn't involve associates pushing manual carts through a large warehouse with training times of 2-3 weeks.

The Smart Warehouse Playbook

Explore how warehouse robotics delivers faster ROI, reduces operational costs, and boosts fulfillment efficiency. This playbook offers data, case studies, and ROI models to guide smart automation decisions.

On-Demand Webinar: Maximize Warehouse Productivity with Flexible Automation

Discover how flexible automation boosts warehouse productivity, cuts labor costs, and delivers unlimited throughput. Watch the on-demand webinar to explore AI-powered strategies for scalable, accurate, and efficient fulfillment.

Warehouse Automation Matters | Episode 18 - Beauty Fulfillment, Perfectly Packed

In this episode, Mary Hart spoke with Austin Feagins from Staci Americas about the complexities of technology and compliance in beauty product fulfillment. They discuss the unique challenges faced by the beauty industry, including high customer expectations and strict regulations.

Boulanger

Quick and easy integration and deployment, along with Locus’s flexibility helps Boulanger exceed customer expectations.

Warehouse Automation Matters | Episode 17 - Agility in Warehouse Operations

Discover how agile supply chain strategies and AI-powered warehouse design help operations stay ahead of market shifts. In this webinar, Mary Hart talks with ThruPut Partners’ Kevin Hume.

Take P2G to 400 UPH with Locus Fast Pick

This white paper explores how Locus Robotics’ Fast Pick functionality helps warehouses achieve up to 400 units per hour by blending the flexibility of Person-to-Goods (P2G) with the speed of Goods-to-Person (G2P) systems. It highlights real-world use cases in e-commerce, healthcare, and retail, showing how Fast Pick boosts throughput, reduces complexity, and adapts to dynamic fulfillment demands.

Warehouse Automation Matters | Episode 16 - Making Data Work for Your Warehouse

Discover how Barrett Distribution Centers leverages data-driven decision-making to optimize warehouse operations. Learn key KPIs, slotting strategies, and AI trends in this Warehouse Automation Matters episode with Derek Morse.

Warehouse Automation Matters | Episode 15 - Improving Retail Warehouses with AI and Robotics

In this conversation, Mary Hart interviewed Barbara Porter, COO of Fragrance.com, about top trends in retail warehouse automation. They discussed the significant impact of AI and robotics on operational efficiency, the importance of sustainability, and the challenges faced when integrating new technologies.