This white paper explores how Locus Robotics’ Fast Pick functionality helps warehouses achieve up to 400 units per hour by blending the flexibility of Person-to-Goods (P2G) with the speed of Goods-to-Person (G2P) systems. It highlights real-world use cases in e-commerce, healthcare, and retail, showing how Fast Pick boosts throughput, reduces complexity, and adapts to dynamic fulfillment demands.

Discover how mezzanines optimize vertical warehouse space with automation, boost efficiency, and future proof operations. Learn design tips and best practices from the “Warehouse Automation Matters” podcast.

Learn how Fast Pick by Locus Robotics enables unlimited warehouse throughput with P2G flexibility. Streamline bulk and high-demand picking for faster, scalable, and efficient fulfillment tailored to dynamic operational needs.

Discover how modern warehouse automation enhances efficiency beyond picking. From case handling to data-driven insights, explore flexible, scalable solutions for your warehouse operations.

In this webinar, Kait Peterson, Vice President of Product Marketing at Locus Robotics was joined by Casimira “Casey” Federspiel and Song Gao of DHL Supply Chain to discuss the reasons for mezzanines and pick towers in a warehouse, along with why integrating automation into these levels is critical for peak optimization.

Implementing vertical storage solutions and robotics can significantly boost warehouse throughput, helping operators manage labor costs, space constraints, and rising demand despite economic uncertainties and limited new warehouse construction.

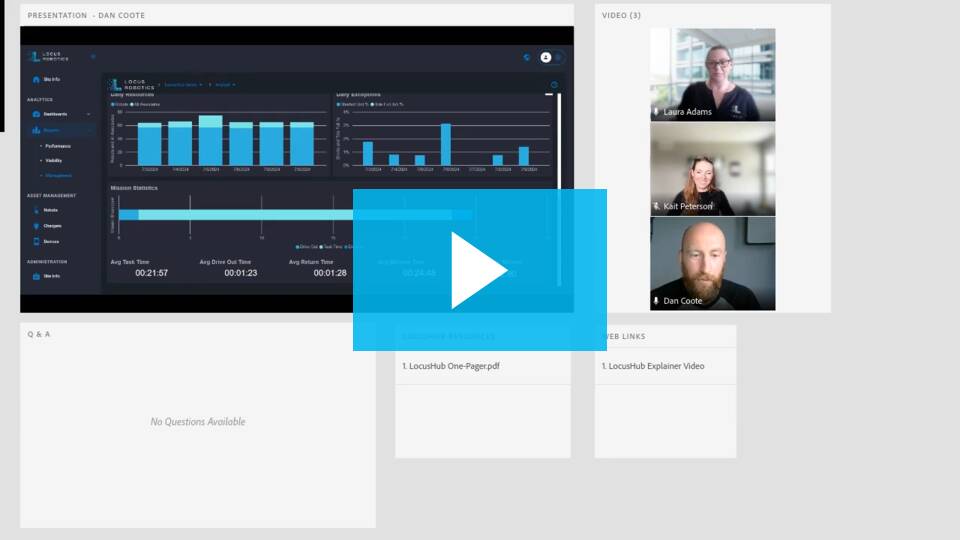

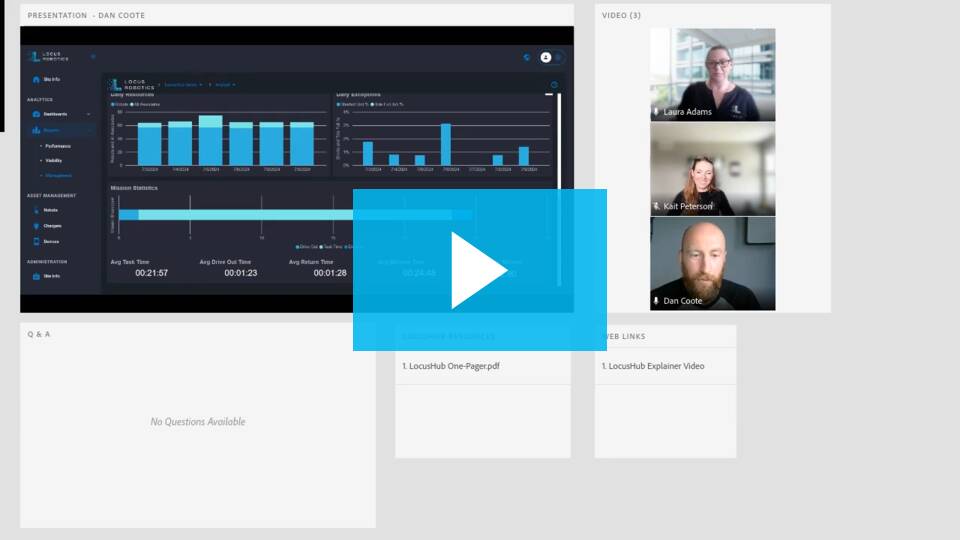

The webinar reviewed LocusHub reports, introduced the Analyst Report, and demonstrated key metrics analysis with timeline graphs.

More than 80% of warehouses aren’t automated because they’re still using old, ineffective manual processes. Use this checklist to determine if your warehouse could be more efficient with automation.

With over 180 locations and four million square meters of storage space, Rhenus Logistics faced a labor challenge in their Hörselgau facility. They implemented Locus Robotics on their mezzanine, which improved training time and increased productivity by over 50%. During peak season, Rhenus scaled up from 135 bots to 162 with the Robots-as-a-Service model. The partnership between Rhenus and Locus has been successful, and they are considering a solution for their level zero with Locus.

For warehouse managers and executives alike, warehouse productivity is top of mind. How can you get as much out of your warehouse space as possible without moving to a new facility?