WP: How to achieve 400 UPH with Locus Fast Pick

WP: How to achieve 400 UPH with Locus Fast Pick Download Now!

How P2G Creates Unlimited Warehouse Throughput with Fast Pick

Mary Hart, Sr. Content Marketing Manager

Picture this: Your warehouse is buzzing with activity as orders flood in from a viral social media promotion on TikTok, and the demand for that product spiked overnight. Normally, this kind of sudden rush would create bottlenecks in your warehouse fulfillment process, leading to slowdowns, inefficiencies, potentially inaccuracies, and missed shipping deadlines. But what if your Person-to-Goods (P2G) solution could provide you with unlimited throughput without the need for the expensive fixed G2P infrastructure that you might be evaluating?

P2G warehouse automation solutions are ideal for warehouses that need unmatched flexibility in their operations and the benefits increase further with Locus Robotics’ Fast Pick functionality, which gives P2G solutions throughput that is even better than traditional G2P solutions.

With Fast Pick, the line between P2G and G2P begins to blur. Fast Pick allows warehouse operations that use P2G to gain throughput without requiring the investment and fixed nature of a fully automated system like an Automated Storage and Retrieval System (AS/RS). It’s like getting the best of both worlds, especially for high-velocity, bulk picking scenarios.

How Fast Pick Works in a Warehouse

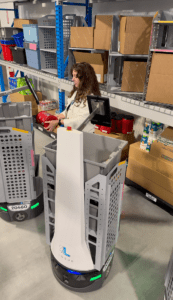

Fast Pick was designed to simplify bulk and high-velocity picking tasks. In a typical P2G solution, associates collaborate with multiple robots, working one at a time in designated aisles to pick goods and place them on the robots for further processing. While associates may need to walk to the next available robot, they still benefit from the efficiency of a multi-bot system. With Fast Pick, the process allows associates to stay relatively stationary to cut down even further on walking time, as multiple robots come to them, stationed at ideal pick locations.

For fast-moving items like promotional goods (such as an item that’s included with each purchase) or viral products, Fast Pick enables associates to pick directly from bulk storage, like pallets or gaylords, rather than having to take the time to unpack and to store items in individual totes or bins first. By picking directly from these larger storage containers, Fast Pick dramatically reduces the number of steps involved in fulfilling orders, allowing for unit-per-hour (UPH) and lines-per-hour (LPH) rates to skyrocket.

Here’s a look at the numbers:

- When you consider that the average manual picking rate is around 40-60 UPH according to industry data, it’s easy to see how Fast Pick can improve your warehouse operations.

- With a single associate working alongside four Locus robots, Fast Pick enables the picking of 300-400 units per hour from bulk locations.

- Add a second associate, and that number can jump to 600-800 UPH without the need for a fixed, complex infrastructure.

Unmatched Flexibility Without the Complexity

Now, let’s talk about warehouse flexibility. Traditional G2P systems, while efficient, can be restrictive as they typically require complex setups with fixed locations for products through an AS/RS or similar fully automated solution. This makes them great for warehouses with highly predictable, repetitive orders, but not so much for fast-changing, dynamic fulfillment needs, which is what we see more of in the warehousing industry.

Now, let’s talk about warehouse flexibility. Traditional G2P systems, while efficient, can be restrictive as they typically require complex setups with fixed locations for products through an AS/RS or similar fully automated solution. This makes them great for warehouses with highly predictable, repetitive orders, but not so much for fast-changing, dynamic fulfillment needs, which is what we see more of in the warehousing industry.

Fast Pick offers a different kind of flexibility for your warehouse. By keeping the human associate at the pick station and relying on autonomous robots to do the “goods-to-person” legwork, warehouses can adjust quickly to surges in demand or changes in product flow. This feature also allows you to manage SKU velocity seamlessly. Each pick location can be programmed dynamically for Fast Pick, so if a SKU is a high runner today and another takes its place tomorrow, no reconfiguration is necessary.

There’s no need to worry about inducting every product into a tightly structured system when Fast Pick allows associates to pick directly from the incoming bulk storage, eliminating several steps from the process. This makes it ideal for:

- High-demand e-commerce products, such as items featured in flash sales or viral trends.

- Retail environments where promotional goods or seasonal items require quick turnover.

- Healthcare logistics, where small but high-volume items need to be picked with speed and accuracy.

When to Consider Fast Pick: More than Just Speed

While Fast Pick offers an undeniable advantage in terms of speed and throughput, the benefits extend beyond just moving items quickly. For warehouses dealing with seasonal peaks, fluctuating demand, or unpredictable trends, Fast Pick provides the kind of agility needed to stay competitive and it's easy to configure and modify.

Think about a time when you had a limited edition product launch and there was a sudden spike in sales as customers rushed to get that product while it was available. Under a traditional P2G system, your associates would have to wait for products to be decanted and fed into an AS/RS or other G2P system before they could locate the items that you’ve brought in for picking, wasting productive time. With Fast Pick, the items can be picked directly from the pallet or bulk storage container as soon as they arrive, bypassing the usual bottlenecks in the process. It’s this ability to “short-circuit” the putaway step that sets Fast Pick apart from other picking systems.

According to research from eMarketer and Insider Intelligence, global eCommerce sales are expected to more than double prepandemic levels by 2025 to $7.4 trillion, and much of that growth is driven by the demand for faster, more efficient delivery times. This means that operations can no longer rely solely on static solutions; they need dynamic systems that can pivot and scale as needed. Fast Pick is built for that exact challenge.

The Future of P2G with a G2P Twist

As warehouse automation continues to evolve, Fast Pick represents the way that warehouses themselves can also evolve for the best. It enhances the strengths of P2G systems by integrating elements of G2P efficiency without the cost, complexity, or rigidity of an ASRS solution.

Warehouse speed isn’t just an advantage; it’s a necessity for any warehouse that wants to stay in business. And with Fast Pick, the distinction between P2G and G2P starts to fade, allowing warehouses to operate at peak efficiency with unmatched flexibility and scalability, even during times of unpredictability.

Fast Pick is just one example of how we’re helping businesses transform their operations, improving throughput, flexibility, and overall performance. Could your warehouse benefit from faster, more efficient fulfillment and unlimited throughput? Let’s talk!