Webinar Registration: The P2G Advantage

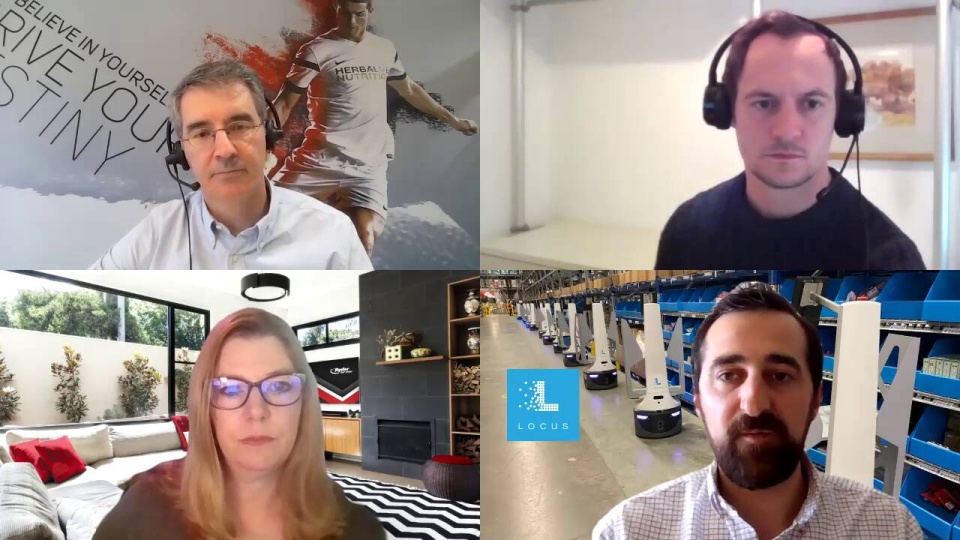

In this informative on-demand webinar, 3PL industry leaders share how they’ve implemented AMRs and warehouse automation to improve:

Webinar Registration: The P2G Advantage LEARN MORE

Today’s 3PLs are utilizing automation and robotics during the fulfillment & put-away processes to unlock productivity, efficiency, and scalability as the world takes a dramatic shift towards online shopping in light of the pandemic.

In this informative on-demand webinar, 3PL industry leaders share how they’ve implemented AMRs and warehouse automation to improve:

Leverage automated systems to mitigate impacts from turbulent patterns of supply and demand in a cost effective and scalable manner

Eliminate unproductive walking and maximize worker output by deploying technology and picking strategies that optimize picking rates in existing warehouses and greenfield buildings

Digitize your returns and reverse logistics to ensure that waste is reduced, assets re-enter the supply chain and your sustainability goals are achieved