Webinar Registration: The P2G Advantage

“When we were picking on the batch cart system, we were averaging 71 units per hour; today, as I’m looking at our board, we’re at 155 UPH.”

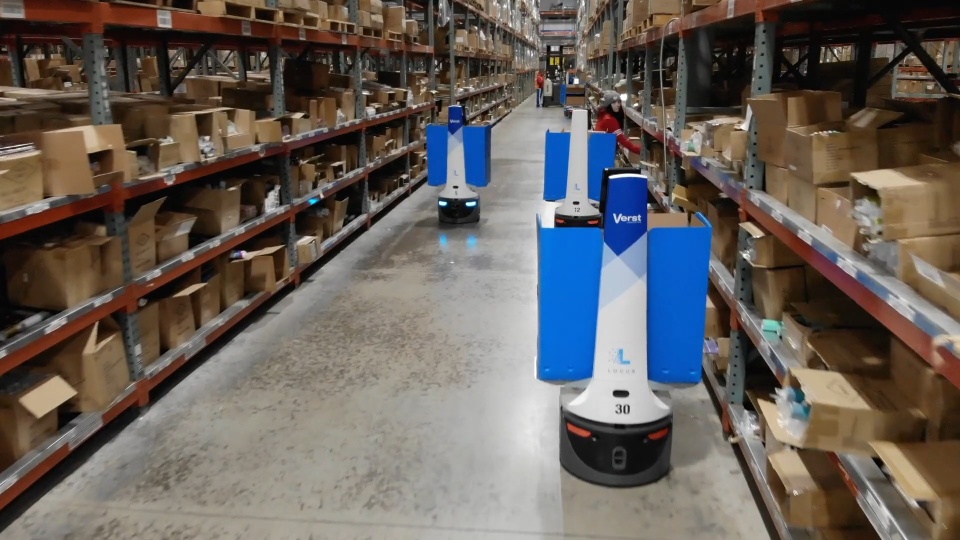

Verst Logistics

Verst Logistics more than doubled its productivity by implementing the Locus solution while reducing onboarding and training costs, doubling pick space square footage, and increasing pick accuracy to 99.9%.