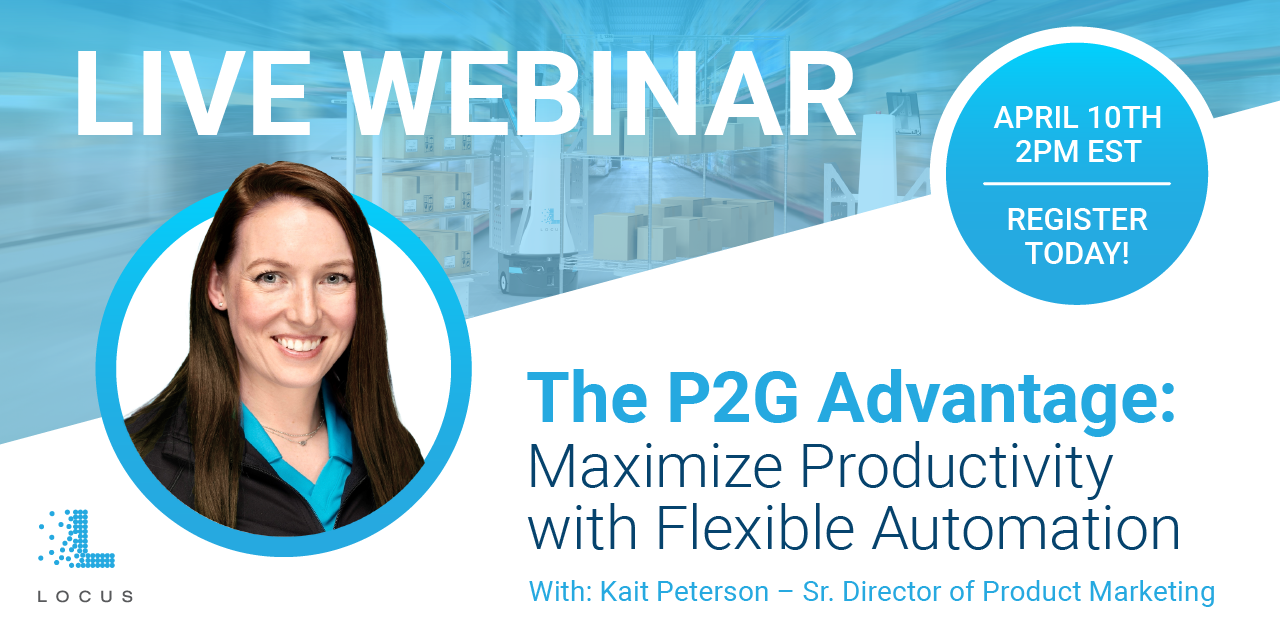

Webinar Registration: The P2G Advantage

Webinar Registration: The P2G Advantage LEARN MORE

Resources

ResourcesWarehouse Automation Content

No results found

Top Advantages of P2G Warehouse Automation

The demand for flexible, scalable solutions that create efficiency and productivity in your warehouse has never been more critical. Download this on-demand webinar to learn the top benefits of Persons-to-Goods (P2G) over Goods-to-Person (G2P) warehouse automation, including: * Streamlined operations * Boosted productivity * Improved accuracy * Increased employee retention Whether you're grappling with fluctuating order volumes, seeking to reduce labor costs, or aiming to enhance your team's efficiency, our Senior Director of Product Marketing, Kait Peterson will illuminate the path to achieving these goals through the strategic adoption of P2G warehouse automation.

Premier® Yarns Doubles Daily Picks with LocusBots

Premier Yarns had a significant surge in online orders, escalating from 20 to 400-500 orders daily, leading to operational challenges including supply shortages. In response, the company collaborated with Carolina Handling to integrate Locus Robotics' technology, enhancing their order processing capacity and efficiency. They doubled their daily shipments to an average of 1,000 per day and improved order shipping time from 5-10 business days to 2-3 days. This technological adoption not only increased pick accuracy and doubled daily picks but also enhanced employee satisfaction by reducing physical strain and improving aisle management.

Concordance innovates healthcare fulfillment with automation

Case Study about GEODIS, which sought to enhance e-commerce fulfillment productivity for a major women's apparel brand during peak seasons despite labor shortages, achieving a 2X productivity improvement with the deployment of 28 LocusBots in their facility.

GEODIS Improves UPH to 98+ with Locus Vector

The GEODIS team decided to use autonomous mobile robots (AMRs) to optimize logistics operations in the warehouse and chose Locus Robotics as their vendor. GEODIS integrated 12 Locus Vector with Cart AMRs across a 40,000 square feet picking area. The Vector AMRs are unique — they can attach and handle carts, allowing for the transportation of heavier products and increasing the throughput of orders per mission."

Rhenus - Higher LPH Mezzanine Picking

Locus Robotics enabled iForce to efficiently manage peak order volumes, surpass forecasts, enhance retention rates, and reduce training time for new associates in their 3PL warehouse operations.

Available in multiple languages

Available in these additional languages

German

Transport Carts Easily with Locus Vector

GEODIS needed an automation solution to help transport cartons of orders in their busy Texas location. They chose Locus Vector with Cart from Locus Robotics to do the carrying and walking for their associates. When orders are ready, Locus Vector with Cart navigates easily through the warehouse aisles, and collects goods from pickers. Once the orders are complete, Locus Vector with cart brings the cartons over for hand off at the packing station. Locus Vector with Cart moves carts and loads/unloads material for warehouse use cases including picking, putaway, cart picking, and more.

The Total Guide to Warehouse Automation

Is your warehouse still relying on outdated, manual processes? Do you struggle with labor shortages, safety issues, and meeting customer demands? Now is the time to evolve.

The 2024 Warehouse Automation Buyer’s Guide for Robotic Solutions

Discover the Right Robotic Automation System to Improve Your Warehouse Operations

New Robots Emerge for Pallet Moving

After the COVID 19 boom in e commerce, many robotic suppliers have shifted and are focusing on the need to efficiently handle boxes, cases, totes, and palettes. In this insightful session, you’ll hear from the moderator, Eugene Demaitre, Editorial Director of Peerless Media; Jason Walker, VP of Market Development at Locus Robotics; and Ruddick Lawrence, CTO and Co-founder of Rapid Robotics.

Bluegrass Supply Chain

Bluegrass Supply Chain has implemented autonomous mobile robots (AMRs) into their logistics operations, resulting in a 200% increase in efficiency and reduced human errors. The AMRs have also allowed for scalability based on demand, resulting in cost savings and improved safety for team members. The integration of AMRs has yielded substantial improvements in efficiency, flexibility, scalability, cost savings, worker safety, customer experience, and sustainability.

How the Locus Robotics AMR Solution is Transforming the Future of Warehousing

"How the Locus Robotics AMR Solution is Transforming the Future of Warehousing" talks about the challenges faced by the warehousing and logistics industry during the COVID-19 pandemic, highlighting the importance of AMRs as a solution to boost productivity in warehouses and thrive in the evolving economic landscape.

Available in multiple languages

Available in these additional languages

Dutch

French

German

Spanish

The Intersection of Public Generative AI, Robotics, and Data Protection

"The Intersection of Public Generative AI, Robotics, and Data Protection" talks about the risks posed by public models of generative AI pose, and how to implement the appropriate controls.